Kev piav qhia txog khoom

WOMIC STEEL kuj muaj lub chaw ua haujlwm tsim khoom zoo rau cov khoom siv hlau casting thiab cov khoom siv hlau forged hauv sab qaum teb Suav teb. Ntau cov khoom siv hlau casting tau muab rau thoob plaws ntiaj teb, xws li Mexico, South-America, Ltalis, Tebchaws Europe, Tebchaws Meskas, Nyiv Pooj, Russia, South-East Asia thiab lwm yam. Nrog rau kev paub txog cov txheej txheem hlau casting thiab forged steel ntau, WOMIC STEEL kuj txhim kho cov txheej txheem thev naus laus zis tas li. Lub iav loj loj ntawm lub tshuab zeb girth, ntau hom iav, iav ncej, txhawb nqa roller, tooj liab mining siv slag pots, tshuab, Electric Shovel spare parts (track shoe), crusher parts (Mantles & Concave, Bowl Liners), thiab lub puab tsaig txav tau tsim los ntawm nws tau nyiam ntau tus neeg siv khoom txawv teb chaws tuaj xyuas lub tuam txhab. Thiab ua rau lawv txaus siab rau peb cov khoom.

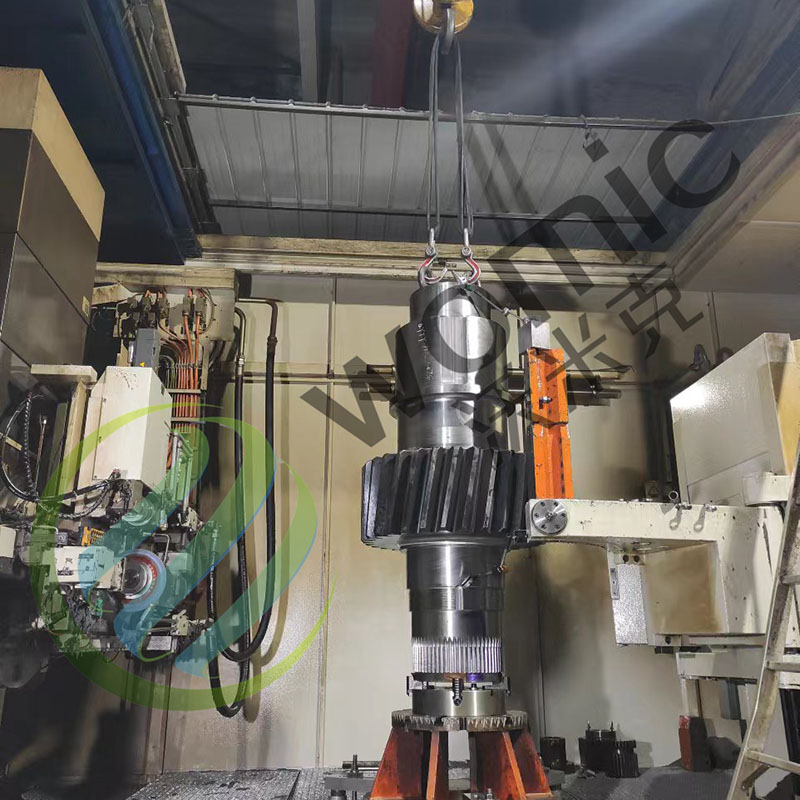

Tom qab 20 xyoo kev tsim khoom thiab kev muag khoom hauv kev lag luam casting, tam sim no peb muaj pab pawg neeg txawj ntse thiab muaj kev paub dhau los, tshwj xeeb hauv kev tsim cov hlau loj thiab loj heev. Cov txheej txheem tsim khoom siv kev sib koom ua ke, kev teeb tsa ib zaug ntawm cov hlau molten 450 tons, thiab qhov hnyav siab tshaj plaws ntawm cov castings tuaj yeem ncav cuag li 300 tons. Kev lag luam khoom lag luam suav nrog kev khawb av, cement, nkoj, forging, metallurgy, choj, kev txuag dej, Ib qho chaw machining (pawg) (5 TK6920 CNC boring thiab milling tshuab, 13 CNC 3.15M ~ 8M ob chav kem ntsug lathe (pawg), 1 CNC 120x3000 hnyav phaj dov tshuab, 6 pawg ntawm φ1.25m-8m iav hobbing tshuab (pawg)) thiab lwm yam.

Cov khoom siv tsim khoom thiab cov khoom siv kuaj tau ua tiav lawm. Lub peev xwm nqa tau siab tshaj plaws ntawm ib lub tsheb yog 300 tons, nrog rau ib lub cub hluav taws xob arc ntawm 30 tons thiab 80 tons, ib lub cub hluav taws xob LF ob chav chaw nres tsheb ntawm 120 tons, ib lub tshuab tua blasting lub rooj tig ntawm 10m * 10m, peb lub cub hluav taws xob kub siab kho cua sov ntawm 12m * 7m * 5m, 8m * 4m * 3.5m, 8m * 4m * 3.3m, thiab 8m * 4M * 3.3m. Thaj chaw lim dej 30,000 square meters hluav taws xob arc cub hluav taws xob tshem tawm cov plua plav.

Lub chaw kuaj mob ywj pheej muaj cov chaw kuaj tshuaj lom neeg, lub tshuab ntsuas nyeem ncaj qha, lub tshuab kuaj kev cuam tshuam, lub tshuab kuaj tensile, lub tshuab kuaj qhov tsis zoo ultrasonic, Leeb hardness tester, Metallographic phase microscope, thiab lwm yam.

Txhua lub sijhawm peb lees txais kev tshuaj xyuas ntawm qhov chaw, yog li koj yuav ntseeg tias cov hlau castings thiab cov khoom forged tsim los ntawm WOMIC STEEL muaj qhov zoo thiab lub neej ntev, uas tuaj yeem ua tau raws li cov neeg siv khoom xav tau.

Yuav kom daws tau qhov teeb meem ntawm kev ua qias tuaj ntau thiab kev siv hluav taws xob ntau,

WOMIC STEEL siv cov cub hluav taws xob nruab nrab zaus thiab cov khoom siv plua plav ntsia rau hauv lub chaw ua haujlwm. Tam sim no, qhov chaw ua haujlwm ntawm lub chaw ua haujlwm tau zoo dua qub. Yav dhau los, coke tau hlawv, tab sis hluav taws xob tam sim no siv, uas tsis tsuas yog txo kev siv hluav taws xob, txuag hluav taws xob thiab tiv thaiv ib puag ncig, tab sis kuj txhim kho qhov tseeb ntawm cov khoom.

WOMIC STEEL yuav txhim kho cov khoom siv kho vajtse ntawm lub Hoobkas, txhawb nqa cov khoom siv automation, kev siv cov txheej txheem tsis siv neeg los khaws cov khoom, kev ntxuav thiab polishing, thiab kev txau tshuaj tsis siv neeg, thiab lwm yam, kom nce qib ntawm kev ua haujlwm tsis siv neeg ntawm cov txheej txheem ntau lawm mus rau ntau dua 90%, thiab txuas ntxiv txhim kho thev naus laus zis.

Qhov sib txawv ntawm cov khoom siv hlau casting thiab cov khoom siv hlau forged:

Ua ntej, cov txheej txheem ntau lawm yog txawv

Cov txheej txheem tsim khoom ntawm kev forgings thiab steel castings yog txawv. Forged steel yog hais txog txhua yam khoom siv forged thiab forgings tsim los ntawm txoj kev forging; Cast steel yog cov hlau siv los casting castings. Forging yog dov cov khoom siv raw mus rau hauv cov duab thiab qhov loj me xav tau los ntawm kev cuam tshuam thiab yas deformation ntawm cov khoom siv hlau. Hauv kev sib piv, steel castings yog ua los ntawm kev nchuav cov hlau molten rau hauv tus qauv ua ntej, uas tau khov thiab txias kom tau txais cov duab thiab qhov loj me xav tau. Forged steel feem ntau yog siv rau hauv kev tsim khoom ntawm qee qhov tseem ceeb ntawm lub tshuab; Cast steel feem ntau yog siv los tsim qee cov duab nyuaj, nyuaj rau forge lossis txiav forming thiab xav tau lub zog siab thiab plasticity qhov chaw.

Qhov thib ob, cov qauv khoom siv sib txawv

Cov qauv khoom ntawm cov forgings thiab steel castings kuj txawv. Cov forgings feem ntau yog sib xws dua thiab muaj lub zog zoo dua thiab qaug zog tiv taus. Vim yog cov qauv crystalline ntom ntom ntawm cov forgings, lawv tsis yooj yim rau deformation thiab thermal cracking thaum raug load. Qhov sib piv, cov qauv ntawm cov hlau cam khwb cia yog xoob, uas yooj yim los tsim cov yas deformation thiab qaug zog puas tsuaj nyob rau hauv qhov kev ua ntawm load.

Qhov thib peb, cov yam ntxwv ntawm kev ua tau zoo sib txawv

Cov yam ntxwv kev ua tau zoo ntawm kev forgings thiab castings kuj txawv. Forgings muaj kev hnav thiab corrosion tsis kam thiab yog tsim rau lub zog siab thiab cov khoom thauj ntau zaus. Nyob rau hauv sib piv, qhov hnav tsis kam thiab corrosion tsis kam ntawm cov hlau cam khwb cia yog qhov tsis zoo, tab sis lawv muaj plasticity zoo.