Kev Taw Qhia:

API 5L yog ib qho qauv txheem uas tau tsim los ntawm American Petroleum Institute (API) rau cov kav hlau tsis muaj qhov thiab cov kav hlau uas siv rau hauv cov txheej txheem thauj mus los hauv kev lag luam roj av thiab roj av. Womic Steel, lub tuam txhab tsim cov kav hlau API 5L, muaj ntau yam khoom uas ua tau raws li ntau qib thiab cov lus qhia. Tsab xov xwm no muab kev sib piv ntxaws ntxaws ntawm cov tshuaj lom neeg, cov khoom siv kho tshuab, thiab cov qauv xeem rau ntau qib API 5L, ob qho tib si PSL1 thiab PSL2 hla peb hom kav dej: ERW (Electric Resistance Welded), LSAW (Longitudinal Submerged Arc Welded), thiab SMLS (Seamless).

Muaj Peev Xwm Tsim Khoom thiab Ntau Yam:

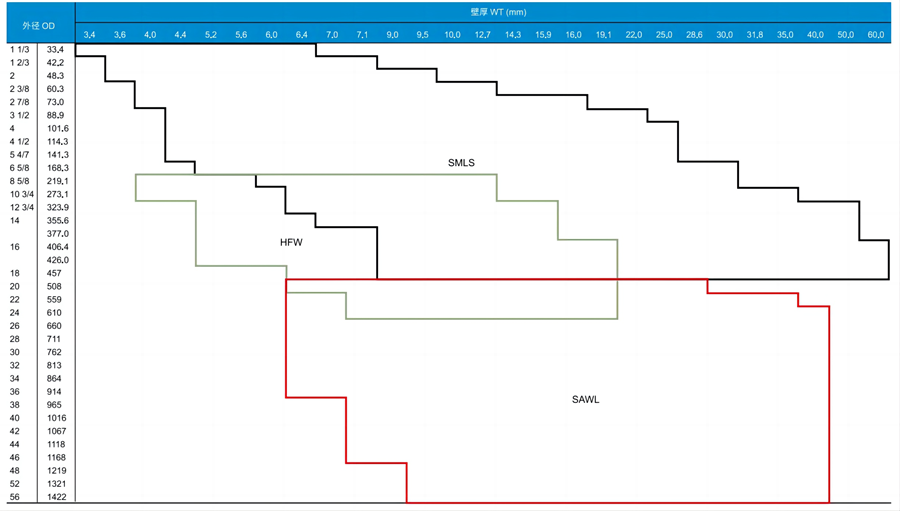

| 制造方法 | 钢级起 | 钢级止 | 外径起 OD Tsawg kawg mm | 外径止 | 壁厚起 | 壁厚止 | 生产能力 |

| SMLS | B | X80Q | 33.4 | 457 | 3.4 | 60 | 200000 |

| HFW | B | X80M | 219.1 | 610 | 4.0 | 19.1 | 200000 |

| SAWL | B | X100M | 508 | 1422 | 6.0 | 40 | 500000 |

Kev kam rau sab nraud

| 标准 | 外径范围 | 外径公差 | 椭圆度 | ||||

| 管体 | 管端 | 管体 | 管端 | ||||

| 无缝 | 焊管 | 无缝 | 焊管 | 无缝 | 焊管 | ||

| API SPEC SO 3183 | D<60.3 hli | +0.4 hli/-0.8 hli | +1.6 hli/-0.4 hli | ||||

| 60.3mm≤D≤168.3mm | +0.75%/-0.75% | ≤2.0% | ≤1.5% | ||||

| 168.3 hli | +0.5%/-0.5% | ||||||

| 320 hli | +1.6 hli/-1.6 hli | ||||||

| 426 hli | +0.75%/-0.75% | +3.2 hli/-3.2 hli | |||||

| 610 hli | +1.0%/-1.0% | +0.5%/-0.5% | ±2.0 hli | ±1.6 hli | ≤1.5% | ≤1.0% | |

| 800 hli | +4 hli/-4 hli | ||||||

| 1000 hli | +1.0%/-1.0% | +4 hli/-4 hli | ≤15 hli | ≤1.0% | |||

| 1300 hli | +1.0%/-1.0% | +4 hli/-4 hli | ≤15 hli | ≤13 hli | |||

Lus Cim: D yog lub nominal sab nraud ntawm lub yeeb nkab.

Kev kam rau siab ntawm phab ntsa tuab

| 标准 | 外径范围 | 壁厚范围 | 壁厚公差 | 壁厚公差 |

| 无缝 | 焊管 | |||

| API SPEC ISO 3183 | - | t≤4.0 hli | +0.6 hli/-0.5 hli | +0.5 hli/-0.5 hli |

| - | 4.0 hli | +15%/-12.5% | ||

| - | 5.0 hli | +10%/-10% | ||

| - | 15.0mmst <25.0 hli | +1.5 hli/-1.5 hli | ||

| - | 25.0mm≤t <30.0 hli | +3.7mm/-3.0mm | ||

| - | 30.0mm≤t <37.0 hli | +3.7 hli/-10.0% | ||

| - | t≥37.0 hli | +10.0%/-10.0% |

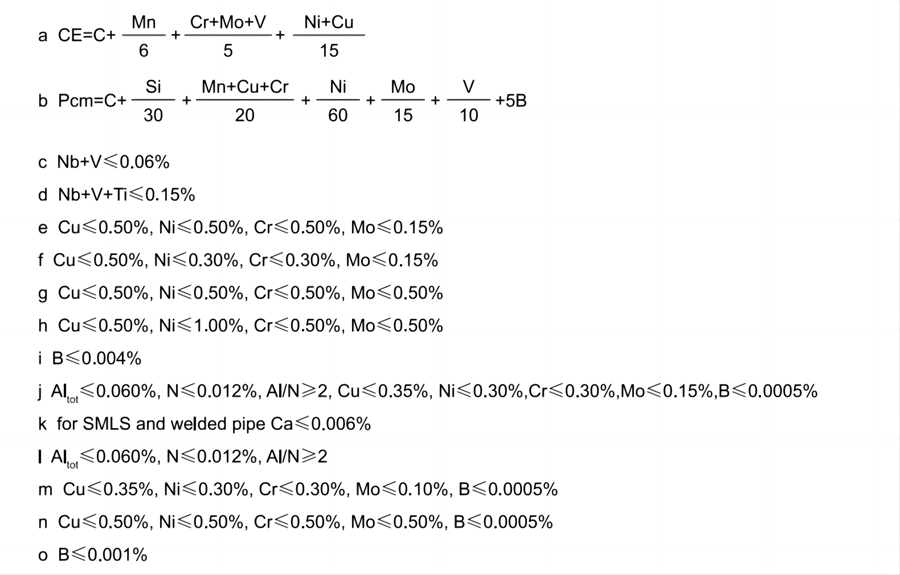

Kev Tshuaj Xyuas Tshuaj

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | T | CE | Pcm | 备注 |

| siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | |||||

| API SPEC 5L | 无缝管 | PSL1 | L210 los yog A | 0.22 |

| 0.90 | 0.030 | 0.030 |

|

|

|

|

| e,o |

| L245 los yog B | 0.28 |

| 1.20 | 0.030 | 0.030 |

|

|

|

|

| c, d, e, o | |||

| L290 los yog X42 | 0.28 |

| 1.30 | 0.030 | 0.030 |

|

|

|

|

| de,o | |||

| L320 los yog X46 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L360 los yog X52 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L390 los yog X56 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L415 los yog X60 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L450 los yog X65 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| ntawm,o | |||

| L485 los yog X70 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| PSL2 | L245N los yog BN | 0.24 | 0.40 | 1.20 | 0.025 | 0.015 |

|

| 0.04 | 0.43 | 0.25 | c,f,o | ||

| L290N los yog X42N | 0.24 | 0.40 | 1.20 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320N los yog X46N | 0.24 | 0.40 | 1.40 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L360N los yog X52N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L390N los yog X56N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L415N los yog X60N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | Raws li tau pom zoo | d,g,o | ||||

| L245Q los yog BQ | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L290Q los yog X42Q | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320Q los yog X46Q | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| 13600 los yog ×52Q | 0.18 | 0.45 | 1.50 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L390Q los yog X56Q | 0.18 | 0.45 | 1.50 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L415Q los yog X60Q | 0.18 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L450Q los yog X65Q | 0.18 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L485Q los yog X70Q | 0.18 | 0.45 | 1.80 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L555Q los yog X80Q | 0.18 | 0.45 | 1.90 | 0.025 | 0.015 |

|

|

| Raws li tau pom zoo | h,i | ||||

| 酸性服 | L245NS los yog BNS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 |

|

| 0.04 | 0.36 | 0.22 | c, d, j, k | ||

| L290NS los yog X42NS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.05 | 0.05 | 0.04 | 0.36 | 0.22 | j,k | |||

| L320NS los yog X46NS | 0.14 | 0.40 | 1.40 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.38 | 0.23 | dj,k | |||

| L360NS los yog X52NS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,j,k | |||

| L245QS los yog BQS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | j,k | |||

| L290QS los yog X42QS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | j,k | |||

| L320QS los yog X46QS | 0.15 | 0.45 | 1.40 | 0.020 | 0.008 | 0.05 | 0.05 | 0.04 | 0.36 | 0.23 | j,k | |||

| L360QS los yog X52QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.39 | 0.23 | d,j,k | |||

| L390QS los yog X56QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.40 | 0.24 | d,j,k | |||

| L415QS los yog X60QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.08 | 0.05 | 0.04 | 0.41 | 0.25 | dj,k | |||

| L450QS los yog X65QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,j,k | |||

| L485QS los yog X70QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,j,k | |||

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | Ti | CEa | Pcm | 备注 |

| siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | |||||

| AP|SPEC 5L | 无缝管 | 海上服 | L245NO los yog BNO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 |

|

| 0.04 | 0.36 | 0.22 | c, d, kuv, m |

| L290NO los yog X42NO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 | 0.36 | 0.22 | l,m | |||

| L320NO los yog X46NO | 0.14 | 0.40 | 1.40 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.38 | 0.23 | d, kuv, m | |||

| L360NO los yog X52NO | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,kuv | |||

| L245QO los yog BQO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | l,m | |||

| L290QO los yog X42Q0 | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | l,m | |||

| L320QO los yog X46QO | 0.15 | 0.45 | 1.40 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 | 0.36 | 0.23 | l,m | |||

| L360QO los yog X52QO | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.39 | 0.23 | d, kuv, n | |||

| L390QO los yog X56Q0 | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.40 | 0.24 | d, kuv, n | |||

| L415QO los yog X60QO | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.08 | 0.05 | 0.04 | 0.41 | 0.25 | d, kuv, n | |||

| L455QO los yog X65QO | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d, kuv, n | |||

| L485Q0 los yog X70Q0 | 0.17 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.05 | 0.06 | 0.42 | 0.25 | d,l,n | |||

| L555QO los yog X80QO | 0.17 | 0.45 | 1.85 | 0.020 | 0.010 | 0.10 | 0.06 | 0.06 | Raws li tau pom zoo | d, kuv, n | ||||

| 焊管 | PSL1 | L245 los yog B | 0.26 |

| 1.20 | 0.030 | 0.030 |

|

|

|

|

| cd,e,c | |

| L290 lossis X42 | 0.26 |

| 1.30 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L320 lossis X46 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L360 los yog X52 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L390 lossis X56 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L415 lossis X60 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L450 los yog X65 | 0.26 |

| 1.45 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L485 los yog X70 | 0.26 |

| 1.65 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| PSL2 | 1245M los yog BM | 0.22 | 0.45 | 1.20 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | ||

| L290M los yog X42M | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320M los yog X46M | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L360M los yog X52M | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,f,o | |||

| L390M los yog X56M | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,f,o | |||

| L415M los yog X60M | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L450M los yog X65M | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L485M los yog X70M | 0.12 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L555M los yog X80M | 0.12 | 0.45 | 1.85 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | T | CEa | Pcm | 备注 |

| siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | |||||

| API SPEC 5L | 焊管 | 酸性服 | L245MS los yog BMS | 0.10 | 0.40 | 1.25 | 0.020 | 0.002 | 0.04 | 0.04 | 0.04 |

| 0.19 | j,k |

| L290MS los yog X42MS | 0.10 | 0.40 | 1.25 | 0.020 | 0.002 | 0.04 | 0.04 | 0.04 |

| 0.19 | j,k | |||

| L320MS los yog X46MS | 0.10 | 0.45 | 1.35 | 0.020 | 0.002 | 0.05 | 0.05 | 0.04 |

| 0.20 | j,k | |||

| L360MS los yog X52MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.05 | 0.06 | 0.04 |

| 0.20 | j,k | |||

| L390MS los yog X56MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.06 | 0.08 | 0.04 |

| 0.21 | d,j,k | |||

| L415MS los yog X60MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.08 | 0.08 | 0.06 |

| 0.21 | d,j,k | |||

| L450MS los yog X65MS | 0.10 | 0.45 | 1.60 | 0.020 | 0.002 | 0.10 | 0.08 | 0.06 |

| 0.22 | d,j,k | |||

| L485MS los yog X70MS | 0.10 | 0.45 | 1.60 | 0.020 | 0.002 | 0.10 | 0.08 | 0.06 |

| 0.22 | dj,k | |||

| 海上服 | L245MO los yog BMO | 0.12 | 0.40 | 1.25 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 |

| 0.19 | l,m | ||

| L290MO los yog X42MO | 0.12 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 |

| 0.19 | l,m | |||

| L320MO los yog X46MO | 0.12 | 0.45 | 1.35 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 |

| 0.20 | Kuv,m | |||

| L360MO los yog X52MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 |

| 0.20 | d, kuv, n | |||

| L390MO los yog X56MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.06 | 0.08 | 0.04 |

| 0.21 | d,l,n | |||

| L415MO los yog X60MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.08 | 0.08 | 0.06 |

| 0.21 | d, kuv, n | |||

| L450MO los yog X65MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.222 | d, kuv, n | |||

| L485MO los yog X70MO | 0.12 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.22 | d,l,n | |||

| L555MO los yog X80MO | 0.12 | 0.45 | 1.85 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.24 | d, kuv, n |

| 标准 | 等级 | 钢级 |

| 屈服强度 | 抗拉强度 | 延伸率 | 屈强比 | 焊缝抗拉强度 |

| API SPEC 5L | PSL1 | L210 los yog A | Tsawg kawg | 210 | 335 | a |

| 335 |

| L245 los yog B | Tsawg kawg | 245 | 415 | a |

| 415 | ||

| L290 los yog X42 | Tsawg kawg | 290 | 415 | a |

| 415 | ||

| L320 los yog X46 | Tsawg kawg | 320 | 435 | a |

| 435 | ||

| L360 los yog X52 | Tsawg kawg | 360 | 460 | a |

| 460 | ||

| L390 los yog X56 | Tsawg kawg | 390 | 490 | a |

| 490 | ||

| L415 los yog X60 | Tsawg kawg | 415 | 520 | a |

| 520 | ||

| L450 los yog X65 | Tsawg kawg | 450 | 535 | a |

| 535 | ||

| L485 los yog X70 | Tsawg kawg | 485 | 570 | a |

| 570 | ||

| PSL2 | L245N los yog BN | Tsawg kawg | 245 | 415 | a |

| 415 | |

| Qhov siab tshaj plaws | 450 | 655 |

| 0.93 |

| |||

| L290N los yog X42N | Tsawg kawg | 290 | 415 | a |

| 415 | ||

| Qhov siab tshaj plaws | 495 | 655 |

| 0.93 |

| |||

| L320N los yog X46N | Tsawg kawg | 320 | 435 | a |

| 435 | ||

| Qhov siab tshaj plaws | 525 | 655 |

| 0.93 |

| |||

| L360N los yog X52N | Tsawg kawg | 360 | 460 | a |

| 460 | ||

| Qhov siab tshaj plaws | 530 | 760 |

| 0.93 |

| |||

| L390N los yog X56N | Tsawg kawg | 390 | 490 | a |

| 490 | ||

| Qhov siab tshaj plaws | 545 | 760 |

| 0.93 |

| |||

| L415N los yog X60N | Tsawg kawg | 415 | 520 | a |

| 520 | ||

| Qhov siab tshaj plaws | 565 | 760 |

| 0.93 |

| |||

| L450Q los yog X65Q | Tsawg kawg | 450 | 535 | a |

| 535 | ||

| Qhov siab tshaj plaws | 600 | 760 |

| 0.93 |

| |||

| L485Q los yog X70Q | Tsawg kawg | 485 | 570 | a |

| 570 | ||

| Qhov siab tshaj plaws | 635 | 760 |

| 0.93 |

| |||

| L555Q los yog X80Q | Tsawg kawg | 555 | 625 | a |

| 625 | ||

| Qhov siab tshaj plaws | 705 | 825 |

| 0.93 |

| |||

| L625M los yog X90M | Tsawg kawg | 625 | 695 | a |

| 695 | ||

| Qhov siab tshaj plaws | 775 | 915 |

| 0.95 |

| |||

| L690M los yog X100M | Tsawg kawg | 690 | 760 | a |

| 760 | ||

| Qhov siab tshaj plaws | 840 | 990 |

| 0.97 |

| |||

| L830M los yog X120M | Tsawg kawg | 830 | 915 | a |

| 915 | ||

| Qhov siab tshaj plaws | 1050 | 1145 |

| 0.99 |

| 标准 | 等级 | 钢级 |

| 屈服强度 | 抗拉强度 | 延伸率 | 屈强比 | 焊缝抗拉强度 |

| API SPEC 5L | 酸性服 | L245NS los yog BNS | Tsawg kawg | 245 | 415 | a |

| 415 |

| Qhov siab tshaj plaws | 450 | 655 |

| 0.93 |

| |||

| L290NS los yog X42NS | Tsawg kawg | 290 | 415 | a |

| 415 | ||

| Qhov siab tshaj plaws | 495 | 655 |

| 0.93 |

| |||

| L320NS los yog X46NS | Tsawg kawg | 320 | 435 | a |

| 435 | ||

| Qhov siab tshaj plaws | 525 | 655 |

| 0.93 |

| |||

| L360NS los yog X52NS | Tsawg kawg | 360 | 460 | a |

| 460 | ||

| Qhov siab tshaj plaws | 530 | 760 |

| 0.93 |

| |||

| L390QS los yog X56QS | Tsawg kawg | 390 | 490 | a |

| 490 | ||

| Qhov siab tshaj plaws | 545 | 760 |

| 0.93 |

| |||

| L415QS los yog X60QS | Tsawg kawg | 415 | 520 | a |

| 520 | ||

| Qhov siab tshaj plaws | 565 | 760 |

| 0.93 |

| |||

| L450QS los yog X65QS | Tsawg kawg | 450 | 535 | a |

| 535 | ||

| Qhov siab tshaj plaws | 600 | 760 |

| 0.93 |

| |||

| L485QS los yog X70QS | Tsawg kawg | 485 | 570 | a |

| 570 | ||

| Qhov siab tshaj plaws | 635 | 760 |

| 0.93 |

| |||

| 海上服 | L245NO los yog BNO | Tsawg kawg | 245 | 415 | a | - | 415 | |

| Qhov siab tshaj plaws | 450 | 655 |

| 0.93 |

| |||

| L290NO los yog X42NO | Tsawg kawg | 290 | 415 | a |

| 415 | ||

| Qhov siab tshaj plaws | 495 | 655 |

| 0.93 |

| |||

| L320NO los yog X46NO | Tsawg kawg | 320 | 435 | a |

| 435 | ||

| Qhov siab tshaj plaws | 520 | 655 |

| 0.93 |

| |||

| L360NO los yog X52NO | Tsawg kawg | 360 | 460 | a |

| 460 | ||

| Qhov siab tshaj plaws | 525 | 760 |

| 0.93 |

| |||

| L390QO los yog X56QO | Tsawg kawg | 390 | 490 | a |

| 490 | ||

| Qhov siab tshaj plaws | 540 | 760 |

| 0.93 |

| |||

| L415QO los yog X60QO | Tsawg kawg | 415 | 520 | a | - | 520 | ||

| Qhov siab tshaj plaws | 565 | 760 |

| 0.93 |

| |||

| L450QO los yog X65QO | Tsawg kawg | 450 | 535 | a | - | 535 | ||

| Qhov siab tshaj plaws | 570 | 760 |

| 0.93 |

| |||

| L485Q0 los yog X70Q0 | Tsawg kawg | 485 | 570 | a |

| 570 | ||

| Qhov siab tshaj plaws | 605 | 760 |

| 0.93 |

| |||

| L555QO los yog X80QO | Tsawg kawg | 555 | 625 | a |

| 625 | ||

| Qhov siab tshaj plaws | 675 | 825 |

| 0.93 |

Lus Cim: a: Qhov tsawg kawg nkaus elongation siv cov qauv hauv qab no: A1 = 1940 * A0.2 / U0.9

| 钢级 | 管体最小横向冲击功(1(2)(3) | 焊缝最小横向冲击功(1(2(3)) | |||||

| D≤508 | 508 hli | 762 hli | 914 hli | 1219 hli | D <1422 hli | D = 1422 hli | |

| ≤L415 lossis X60 | 27(20) | 27(20) | 40(30) | 40(30) | 40(30) | 27(20) | 40(30) |

| >L415 los yog X60 | 27(20) | 27(20) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) |

| >L450 los yog X65 | 27(20) | 27(20) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) |

| >L485 los yog X70 | 40(30) | 40(30) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) |

Lus Cim: (1) Cov nqi hauv lub rooj yuav tsum haum rau cov qauv loj tag nrho.

(2) Tus nqi sab hauv bracket yog tus nqi tsawg kawg nkaus, sab nraud bracket yog tus nqi nruab nrab.

(3) Kub Ntsuas: 0°C.

Cov Qauv Kev Xeem:

Cov kav dej API 5L uas Womic Steel tsim tawm raug kuaj xyuas kom zoo kom ntseeg tau tias lawv ua tau raws li cov qauv zoo tshaj plaws. Cov qauv kuaj suav nrog:

Kev Tshuaj Xyuas Tshuaj:

Cov tshuaj lom neeg ntawm cov hlau raug tshuaj xyuas kom paub tseeb tias nws ua tau raws li cov kev cai ntawm API 5L specification.

Kev tshuaj ntsuam tshuaj lom neeg yog ua los ntawm kev siv lub tshuab ntsuas ncaj qha los txiav txim siab qhov sib xyaw ua ke ntawm cov hlau.

Kev Ntsuas Tshuab:

Cov khoom siv kho tshuab xws li lub zog tawm los, lub zog tensile, thiab elongation raug sim kom ntseeg tau tias lawv ua tau raws li cov kev cai tshwj xeeb.

Kev kuaj xyuas tshuab yog ua tiav los ntawm kev siv lub tshuab kuaj tensile 60-tuj los ntsuas lub zog thiab ductility ntawm cov hlau.

Kev Ntsuas Hydrostatic:

Kev sim hydrostatic yog ua los xyuas qhov kev ncaj ncees ntawm cov yeeb nkab thiab xyuas kom meej tias nws tuaj yeem tiv taus qhov kev xav tau siab ntawm nws daim ntawv thov.

Cov kav dej raug ntim nrog dej thiab raug rau siab, nrog rau lub sijhawm sim thiab qib siab uas tau teev tseg los ntawm cov qauv API 5L.

Kev Ntsuas Tsis Ua Rau Puas Tsuaj (NDT):

Cov txheej txheem NDT xws li kev kuaj ultrasonic (UT) thiab kev kuaj cov khoom sib nqus (MT) yog siv los nrhiav cov qhov tsis zoo lossis kev tsis sib txuas hauv cov yeeb nkab.

UT siv los txheeb xyuas cov qhov tsis zoo sab hauv, thaum MT siv los nrhiav cov qhov tsis zoo ntawm qhov chaw.

Kev Ntsuas Kev Cuam Tshuam:

Kev ntsuam xyuas kev cuam tshuam yog ua los ntsuas qhov tawv ntawm cov hlau ntawm qhov kub qis.

Qhov kev sim cuam tshuam Charpy feem ntau yog siv los ntsuas lub zog cuam tshuam uas cov hlau nqus tau.

Kev Ntsuas Qhov Nyuaj:

Kev ntsuam xyuas qhov nyuaj yog ua los ntsuas qhov nyuaj ntawm cov hlau, uas tuaj yeem qhia nws lub zog thiab kev haum rau cov ntawv thov tshwj xeeb.

Kev ntsuas Rockwell hardness feem ntau yog siv los ntsuas qhov nyuaj ntawm cov hlau.

Kev Tshuaj Xyuas Microstructure:

Kev tshuaj xyuas microstructure yog ua los ntsuam xyuas cov qauv nplej thiab qhov zoo ntawm cov hlau.

Lub tshuab microscope metallurgical siv los tshuaj xyuas cov microstructure ntawm cov hlau thiab txheeb xyuas txhua yam tsis zoo.

Los ntawm kev ua raws li cov qauv kev xeem nruj no, Womic Steel ua kom nws cov kav dej API 5L ua tau raws li qhov yuav tsum tau ua zoo tshaj plaws thiab muab kev ua tau zoo hauv ntau yam kev siv hauv kev lag luam.

Txheej Txheem Tsim Khoom:

1. Cov Kav Hlau Tsis Muaj Qhov Txuas:

- Kev Xaiv Khoom Siv Raw: Cov hlau billets zoo raug xaiv rau kev tsim cov kav hlau seamless.

- Kev Ua Kub thiab Kev Tho: Cov billets raug cua sov rau qhov kub siab thiab tom qab ntawd tho kom tsim tau lub plhaub khoob.

- Dov thiab Sizing: Lub plhaub tho qhov ces dov thiab ncab mus rau qhov inch thiab thickness xav tau.

- Kev Kho Mob Kub: Cov kav dej raug rau cov txheej txheem kho mob kub xws li annealing lossis normalizing kom txhim kho lawv cov khoom siv kho tshuab.

- Kev Ua Tiav: Cov kav dej dhau los ntawm cov txheej txheem ua tiav xws li kev ncaj, txiav, thiab kev tshuaj xyuas.

- Kev Ntsuas: Cov kav dej raug kuaj ntau yam, suav nrog kev ntsuas hydrostatic, kev ntsuas ultrasonic, thiab kev ntsuas eddy tam sim no, kom ntseeg tau tias lawv zoo.

- Kev Kho Mob Nto: Cov kav dej yuav raug coated lossis kho kom tiv thaiv kev xeb thiab txhim kho lawv qhov tsos.

- Ntim thiab Xa Khoom: Cov kav dej raug ntim thiab xa mus rau cov neeg siv khoom kom zoo.

2. LSAW (Longitudinal Submerged Arc Vuam) Cov Kav Hlau:

- Kev Npaj Phaj: Cov phaj hlau zoo tau npaj rau kev tsim cov kav dej LSAW.

- Kev Tsim: Cov phaj raug tsim ua ib daim duab "U" siv lub tshuab ua ntej khoov.

- Kev Vuam: Cov phaj zoo li "U" ces raug vuam ua ke siv cov txheej txheem vuam submerged arc.

- Kev nthuav dav: Cov xov hlau txuas tau nthuav dav mus rau qhov txoj kab uas xav tau siv lub tshuab nthuav dav sab hauv lossis sab nraud.

- Kev Tshuaj Xyuas: Cov kav dej raug tshuaj xyuas seb puas muaj qhov tsis zoo thiab qhov loj me.

- Kev Ntsuas Ultrasonic: Cov kav dej raug kuaj ultrasonic kom pom cov qhov tsis zoo sab hauv.

- Beveling: Cov yeeb nkab kawg yog beveled rau vuam.

- Kev Txheej thiab Cim: Cov kav dej yuav raug txheej thiab cim raws li cov neeg siv khoom xav tau.

- Ntim thiab Xa Khoom: Cov kav dej tau ntim thiab xa mus rau cov neeg siv khoom.

3. HFW (Kev Vuam Zaus Siab) Cov Kav Hlau:

- Kev Npaj Coil: Cov coils hlau tau npaj rau kev tsim cov kav dej HFW.

- Kev Tsim thiab Vuam: Cov kauj vuam raug tsim ua ib lub cylindrical thiab tom qab ntawd welded siv kev vuam zaus siab.

- Kev Kub Weld Seam: Lub weld seam raug cua sov rau qhov kub vuam siv siv cov cua sov induction siab.

- Kev Ntsuas: Cov yeeb nkab vuam raug ntsuas raws li qhov xav tau txoj kab uas hla thiab tuab.

- Kev Txiav thiab Beveling: Cov yeeb nkab raug txiav mus rau qhov ntev xav tau thiab cov kawg raug beveled rau kev vuam.

- Kev Tshuaj Xyuas: Cov kav dej raug tshuaj xyuas seb puas muaj qhov tsis zoo thiab qhov loj me.

- Kev Ntsuas Hydrostatic: Cov kav dej raug kuaj xyuas seb puas muaj zog thiab xau los ntawm kev siv kev ntsuas hydrostatic.

- Kev Txheej thiab Cim: Cov kav dej raug txheej thiab cim raws li cov neeg siv khoom xav tau.

- Ntim thiab Xa Khoom: Cov kav dej tau ntim thiab xa mus rau cov neeg siv khoom.

Cov txheej txheem tsim khoom ntxaws ntxaws no ua kom ntseeg tau tias muaj qhov zoo thiab kev ntseeg siab ntawm cov kav dej hlau tsis muaj qhov tsis sib xws, LSAW, thiab HFW uas Womic Steel tsim tawm, ua tau raws li cov kev cai nruj ntawm ntau yam lag luam.

Kev Kho Mob Nto:

Kev kho qhov chaw ntawm cov kav dej hlau yog qhov tseem ceeb rau kev txhim kho nws txoj kev tiv thaiv corrosion thiab kev pabcuam lub neej. Womic Steel siv ntau txoj kev kho qhov chaw nyob ntawm ntau yam kev xav tau los ntawm cov neeg siv khoom, suav nrog:

1. Kev Kub-Dip Galvanizing: Cov yeeb nkab hlau raug muab tso rau hauv cov zinc molten los tsim cov txheej tiv thaiv zinc-hlau alloy, txhim kho nws txoj kev tiv thaiv corrosion. Kev kub-dip galvanizing yog qhov tsim nyog rau cov kav dej ib txwm muaj thiab cov kav dej siab qis.

2. Cov Tshuaj Pleev Xim Tiv Thaiv Kev Xeb: Cov tshuaj pleev xim tiv thaiv kev xeb feem ntau suav nrog cov tshuaj pleev xim epoxy, cov tshuaj pleev xim polyethylene, thiab cov tshuaj pleev xim polyurethane. Cov tshuaj pleev xim no tiv thaiv kev oxidation thiab xeb ntawm qhov chaw ntawm cov yeeb nkab hlau, ua rau nws lub neej ua haujlwm ntev dua.

3. Kev Siv Xuab Zeb: Kev siv tshuab xuab zeb ceev ceev yog siv los ntxuav cov yeeb nkab hlau, tshem tawm xeb thiab cov khoom tsis huv ntawm qhov chaw, muab lub hauv paus zoo rau kev kho cov txheej txheem tom ntej.

4. Kev Kho Kom Zoo: Cov yeeb nkab hlau nto tuaj yeem pleev xim nrog cov xim tiv thaiv xeb, cov xim asphalt, thiab lwm yam xim kom txhim kho nws txoj kev tiv thaiv xeb, tsim nyog rau cov kav dej hauv av thiab cov kav dej hauv cov chaw ib puag ncig marine.

Cov txheej txheem kho saum npoo no tiv thaiv cov kav dej hlau kom tsis txhob xeb thiab puas tsuaj, ua kom nws ntseeg tau thiab ruaj khov hauv ntau qhov chaw ib puag ncig hnyav.

Ntim thiab Kev Thauj Mus Los:

Womic Steel ua kom muaj kev ntim khoom zoo thiab kev thauj mus los ntawm cov kav dej hlau, muab cov kev xaiv yooj ywm kom tau raws li ntau yam kev xav tau ntawm cov neeg siv khoom:

1. Kev Thauj Khoom Loj: Yog tias koj xaj ntau, cov hlau kav dej tuaj yeem xa tuaj ua ntau siv cov neeg thauj khoom loj tshwj xeeb. Cov hlau raug thauj ncaj qha rau hauv lub nkoj yam tsis muaj ntim khoom, tsim nyog rau kev thauj khoom ntau yam uas pheej yig.

2. LCL (Tsawg dua Lub Thawv Thauj Khoom): Rau cov xaj me me, cov hlau kav dej tuaj yeem xa tuaj ua LCL cargo, qhov twg ntau daim ntawv xaj me me raug muab tso ua ke rau hauv ib lub thawv. Txoj kev no pheej yig rau cov khoom me me thiab muab cov sijhawm xa khoom yooj yim dua.

3. FCL (Thawv Thauj Khoom Tag Nrho): Cov neeg siv khoom tuaj yeem xaiv kev xa khoom FCL, qhov twg ib lub thawv puv nkaus rau lawv qhov kev txiav txim. Txoj kev no ua rau lub sijhawm thauj khoom sai dua thiab txo qhov kev pheej hmoo ntawm kev puas tsuaj thaum lub sijhawm tuav.

4. Kev Thauj Khoom Los Ntawm Huab Cua: Yog tias koj xav tau kev pab sai, kev thauj khoom los ntawm huab cua muaj rau kev xa khoom sai. Txawm hais tias kim dua li kev thauj khoom los ntawm dej hiav txwv, kev thauj khoom los ntawm huab cua muab kev thauj mus los sai thiab txhim khu kev qha rau kev xa khoom uas xav tau lub sijhawm ceev.

Womic Steel ua kom ntseeg tau tias txhua yam khoom xa tuaj raug ntim kom ruaj ntseg kom tiv thaiv kev puas tsuaj thaum lub sijhawm thauj mus los. Cov hlau feem ntau yog qhwv rau hauv cov ntaub ntawv tiv thaiv thiab khi rau hauv cov thawv lossis ntawm cov pallets kom ntseeg tau tias muaj kev ruaj khov thaum lub sijhawm thauj mus los. Tsis tas li ntawd, lub tuam txhab ua haujlwm nrog cov neeg koom tes xa khoom muaj npe nrov kom ntseeg tau tias kev xa khoom raws sijhawm thiab kev tswj hwm kev thauj mus los zoo.

Cov Xwm Txheej Thov:

Cov kav dej API 5L uas Womic Steel tsim tawm yog siv dav hauv kev lag luam roj av thiab roj av rau kev thauj mus los ntawm roj, roj av, thiab lwm yam kua dej. Lawv kuj siv rau hauv ntau yam lag luam xws li kev ua tshuaj lom neeg, kev tsim hluav taws xob, thiab kev tsim kho.

Xaus lus:

Womic Steel yog ib lub tuam txhab tsim cov kav dej API 5L uas ntseeg siab tau, muab cov khoom zoo uas ua tau raws li cov kev cai nruj ntawm cov roj av thiab cov roj av. Nrog rau kev tsom mus rau qhov zoo, kev ntseeg siab, thiab kev txaus siab ntawm cov neeg siv khoom, Womic Steel tseem yog qhov kev xaiv zoo rau cov neeg siv khoom thoob ntiaj teb.

Lub sijhawm tshaj tawm: Lub Peb Hlis-22-2024