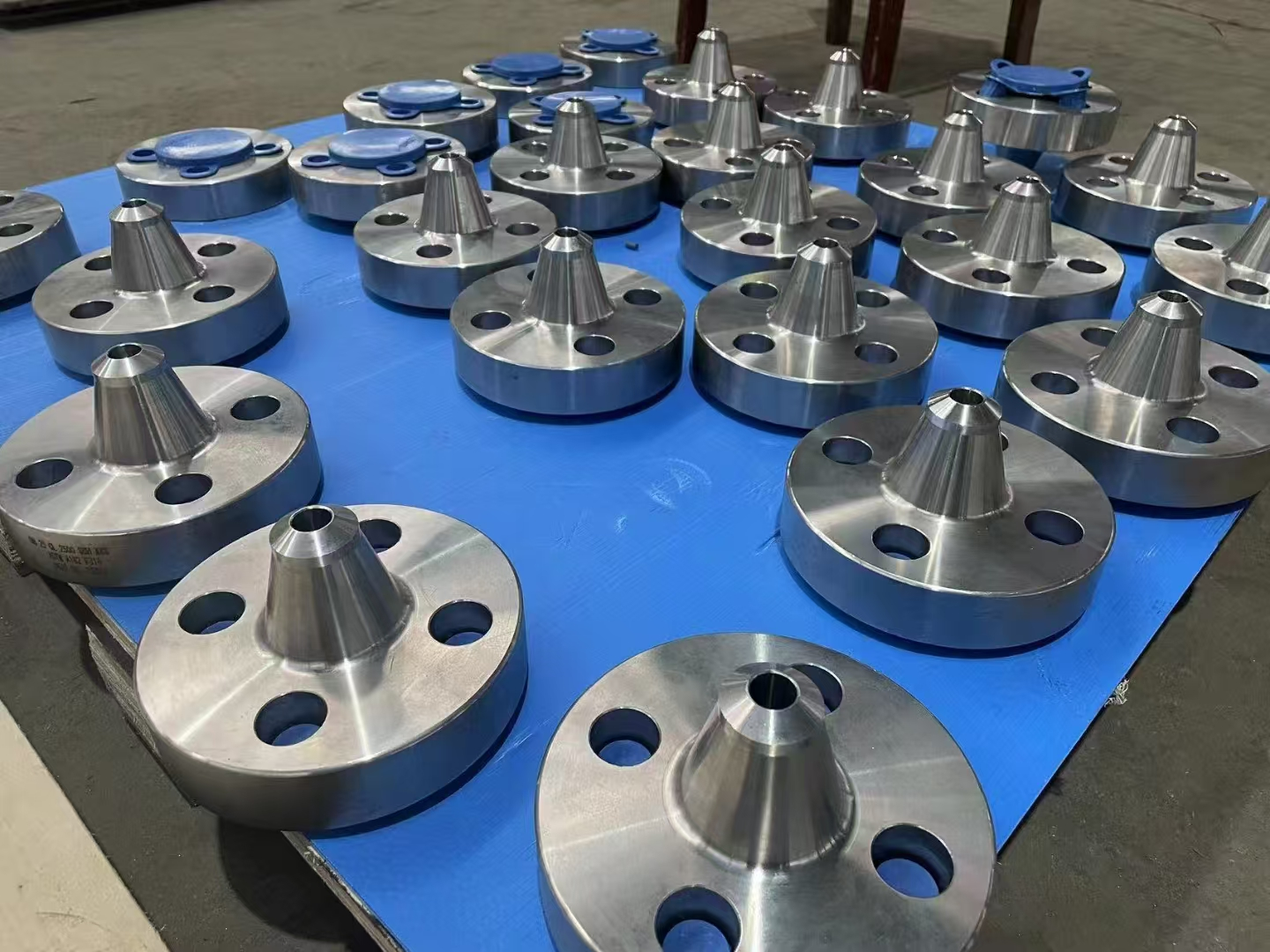

ASTM A182 Cov Flanges Hlau Uas Tau Forged Los Yog Rolled Alloy-Steel, Cov Khoom Siv Forged, Thiab Cov Li Qub

ASTM A182 yog ib qho tseem ceeb rau cov flanges hlau uas raug forged los yog dov, cov khoom siv forged, thiab cov li qub uas tsim los siv rau hauv qhov kub thiab txias thiab siab. Cov qauv no muab cov lus qhia rau cov tshuaj lom neeg sib xyaw, cov khoom siv kho tshuab, cov txheej txheem sim, thiab lwm yam tseem ceeb uas ua kom ntseeg tau tias cov khoom no ruaj khov thiab ntseeg tau hauv cov ntawv thov tseem ceeb.

Ntawm Womic Steel, peb tsim ntau yam khoom uas ua raws li ASTM A182 tus qauv, muab cov khoom zoo tshaj plaws thiab kev ua haujlwm raug. Hauv tsab xov xwm no, peb yuav tshawb nrhiav cov ntsiab lus tseem ceeb ntawm tus qauv no thiab qhia txog Womic Steel lub peev xwm tsim khoom thiab cov txiaj ntsig ntawm kev xaiv peb ua koj tus neeg muag khoom.

Cov Hom Khoom Uas ASTM A182 Them

ASTM A182 npog ntau yam khoom siv hlau forged lossis dov, suav nrog:

1. Cov flanges - Cov no yog siv los txuas cov kav dej, cov li qub, cov twj tso kua mis, thiab lwm yam khoom siv hauv lub kaw lus kav dej.

2. Cov Khoom Siv Forged - Cov no suav nrog lub luj tshib, tees, reducers, caps, thiab unions siv rau hauv cov kab ke siab.

3. Cov Li Qub - Tsim los rau kev tswj cov dej ntws hauv qhov chaw kub siab.

4. Lwm Cov Khoom Forged lossis Rolled - Cov no suav nrog cov li qub thiab cov fittings siv rau hauv cov pa dej, roj, thiab lwm yam tshuab siab.

Ntawm Womic Steel, peb tsim cov khoom no hauv ntau qhov ntau thiab tsawg, cov ntaub ntawv, thiab cov qauv teeb tsa, kom ntseeg tau tias lawv ua tau raws li koj cov kev xav tau tshwj xeeb.

Cov Khoom Siv thiab Cov Tshuaj Lom Zem

Tus qauv ASTM A182 qhia txog ntau qib khoom siv, suav nrog cov hlau carbon, cov hlau tsis tshua muaj alloy, thiab cov hlau tsis xeb, txhua tus muaj cov kev cai sib txawv ntawm cov tshuaj lom neeg. Nov yog qee cov ntaub ntawv tseem ceeb uas suav nrog hauv ASTM A182:

1. Qib F1 - Cov hlau carbon nrog cov khoom sib xyaw uas tso cai rau nws ua haujlwm hauv qhov kub nruab nrab.

2. Qib F5, F9, F11, F22 - Cov hlau tsis tshua muaj hlau uas tsim los kom tiv taus qhov kub thiab txias thiab kev nyuaj siab ntau dua.

3. Qib F304, F304L, F316, F316L - Cov hlau tsis xeb Austenitic, siv dav rau lawv txoj kev tiv thaiv xeb hauv ntau qhov chaw ua tshuaj lom neeg.

Rau txhua qib, cov tshuaj lom neeg raug tswj hwm kom zoo kom ua tau raws li cov kev cai ASTM nruj. Hauv qab no yog cov ntsiab lus rau txhua yam khoom siv cov tshuaj lom neeg thiab cov khoom siv kho tshuab.

Cov Tshuaj Lom Zem thiab Cov Khoom Siv Kho Tshuab

1. Qib F1 - Cov Hlau Carbon

Cov Tshuaj Muaj pes tsawg leeg:

Cov pa roj carbon (C): 0.30-0.60%

Manganese (Mn): 0.60-0.90%

Silicon (Si): 0.10-0.35%

Sulfur (S): ≤ 0.05%

Phosphorus (P): ≤ 0.035%

Cov Khoom Siv Kho Tshuab:

Lub zog Tensile (MPa): ≥ 485

Lub zog tawm los (MPa): ≥ 205

Kev ntev (%): ≥ 20

2. Qib F5 - Hlau Alloy Qis

Cov Tshuaj Muaj pes tsawg leeg:

Cov pa roj carbon (C): 0.10-0.15%

Manganese (Mn): 0.50-0.80%

Chromium (Cr): 4.50-5.50%

Molybdenum (Mo): 0.90-1.10%

Sulfur (S): ≤ 0.03%

Phosphorus (P): ≤ 0.03%

Cov Khoom Siv Kho Tshuab:

Lub zog Tensile (MPa): ≥ 655

Lub zog tawm los (MPa): ≥ 345

Kev ntev (%): ≥ 20

3. Qib F304 - Austenitic Stainless Steel

Cov Tshuaj Muaj pes tsawg leeg:

Cov pa roj carbon (C): ≤ 0.08%

Manganese (Mn): 2.00-2.50%

Chromium (Cr): 18.00-20.00%

Nickel (Ni): 8.00-10.50%

Sulfur (S): ≤ 0.03%

Phosphorus (P): ≤ 0.045%

Cov Khoom Siv Kho Tshuab:

Lub zog Tensile (MPa): ≥ 515

Lub zog tawm los (MPa): ≥ 205

Kev ntev (%): ≥ 40

4. Qib F316 - Austenitic Stainless Steel (Tiv Thaiv Kev Kub Ntxhov)

Cov Tshuaj Muaj pes tsawg leeg:

Cov pa roj carbon (C): ≤ 0.08%

Manganese (Mn): 2.00-3.00%

Chromium (Cr): 16.00-18.00%

Nickel (Ni): 10.00-14.00%

Molybdenum (Mo): 2.00-3.00%

Sulfur (S): ≤ 0.03%

Phosphorus (P): ≤ 0.045%

Cov Khoom Siv Kho Tshuab:

Lub zog Tensile (MPa): ≥ 515

Lub zog tawm los (MPa): ≥ 205

Kev ntev (%): ≥ 40

Cov Khoom Siv Kho Tshuab thiab Cov Kev Xav Tau Cuam Tshuam

Cov khoom siv kho tshuab xws li lub zog tensile, lub zog yield, thiab elongation yog qhov tseem ceeb rau kev ua kom ntseeg tau tias cov khoom forged ua haujlwm tau zoo nyob rau hauv kev nyuaj siab. ASTM A182 qhia meej txog cov khoom no rau txhua qib khoom siv, nrog rau cov kev cai sib txawv raws li cov xwm txheej ntawm daim ntawv thov.

Kev ntsuam xyuas kev cuam tshuamyog lwm qhov tseem ceeb ntawm tus qauv, kom ntseeg tau tias cov khoom forged tuaj yeem tiv taus qhov hloov pauv sai sai ntawm qhov kub lossis kev cuam tshuam. Piv txwv li, tus qauv yuav xav tau kev sim Charpy V-notch kom ntseeg tau tias muaj zog hauv qhov kub qis.

Cov Txheej Txheem Tsim Khoom thiab Cov Kev Cai Kho Mob Kub

Womic Steel ua raws li cov txheej txheem tsim khoom nruj kom ntseeg tau tias txhua yam khoom ASTM A182 ua tau raws li cov qauv zoo tshaj plaws. Qhov no suav nrog:

Forging thiab dov - Peb cov tshuab ua haujlwm zoo tshaj plaws ua kom txhua qhov yog forged lossis dov rau qhov ntev thiab kev kam rau siab.

Kev Kho Mob Kub - Kev kho cua sov yog qhov tseem ceeb rau kev ua tiav cov khoom siv kho tshuab xav tau. ASTM A182 xav tau cov voj voog kho cua sov tshwj xeeb nyob ntawm qib khoom siv, xws li annealing, quenching, thiab tempering kom txhim kho kev tawv thiab lub zog.

Kev vuam – Peb muab cov kev daws teeb meem vuam rau cov khoom ASTM A182, kom ntseeg tau tias kev sib txuas txhim khu kev qha thiab tsis xau. Cov txheej txheem vuam raug tswj hwm kom zoo kom ntseeg tau tias cov khoom vuam ua tau raws li lossis tshaj qhov muaj zog ntawm cov khoom siv hauv paus.

Kev Tshuaj Xyuas thiab Kev Ntsuas

Peb ua cov kev pabcuam dav davkev tshuaj xyuas thiab kev simlos xyuas kom meej tias txhua yam khoom ua tau raws li tus qauv ASTM A182. Qhov no suav nrog:

Kev Tshuaj Xyuas Pom - Rau qhov tsis zoo ntawm qhov chaw lossis qhov tsis zoo.

Kev Ntsuas Tsis Ua Rau Puas Tsuaj (NDT) - Xws li kev kuaj ultrasonic thiab kev tshuaj xyuas radiographic kom pom cov qhov tsis zoo sab hauv.

Kev Ntsuas Tshuab - Kev ntsuas lub zog tensile, lub zog yield, thiab kev cuam tshuam los xyuas kom meej tias cov khoom siv ua haujlwm raws li kev ntxhov siab.

Kev Tshuaj Xyuas Tshuaj - Xyuas kom meej tias cov tshuaj lom neeg sib xyaw ua raws li tus qauv qhia.

Tag nrho peb cov khoom raug tswj xyuas kom zoo, thiab peb muab cov ntawv pov thawj kom ntxaws txog kev ua raws li txhua qhov kev txiav txim.

Cov Lus Qhia Txog Khoom thiab Qhov Loj

At Womic Steel, peb muab ntau yam khoom ASTM A182 hauv ntau qhov ntau thiab tsawg thiab cov lus qhia. Peb cov khoomqhov loj mesuav nrog:

Cov flanges: Txij li 1/2" mus txog 60" hauv txoj kab uas hla.

Cov Khoom Siv Forged: Txij li 1/2" mus txog 48" hauv txoj kab uas hla.

Cov li qub: Kev cai loj me kom haum rau koj qhov system xav tau.

Peb cov khoom muaj nyob rau hauv ntau yam kev ntsuas siab thiab cov ntaub ntawv, kom ntseeg tau tias peb tuaj yeem ua tau raws li qhov xav tau tshwj xeeb ntawm koj qhov project.

Cov txiaj ntsig ntawm kev ntim khoom, kev xa khoom, thiab kev thauj mus los

Peb nkag siab txog qhov tseem ceeb ntawm kev xa khoom raws sijhawm thiab ruaj ntseg. Womic Steel muabkev ntim khoom raws li koj xav tauuas tiv thaiv kev ncaj ncees ntawm cov khoom thaum lub sijhawm thauj mus los. Txawm hais tias nws yog los ntawm kev xa khoom hauv thawv lossis kev daws teeb meem tshwj xeeb, peb xyuas kom meej tias koj daim ntawv xaj tuaj txog raws sijhawm thiab nyob rau hauv qhov zoo meej.

Peb likev txawj ntse txog kev thauj mus losthiab kev koom tes ncaj qha nrog cov tuam txhab xa khoom tso cai rau peb muab cov nqi sib tw thiab cov kev daws teeb meem xa khoom yooj ywm.

Kev Kho Kom Haum thiab Cov Kev Pabcuam Ntxiv

Ntxiv rau peb cov khoom lag luam txheem ntau yam, Womic Steel muajkev tsim khoom tshwj xeebrau cov kev xav tau tshwj xeeb. Peb tuaj yeem hloov kho qhov loj me, cov ntaub ntawv, thiab cov khoom tiav kom haum rau koj daim ntawv thov tshwj xeeb.

Cov Kev Pabcuam Ua Haujlwmsuav nrog:

Kev siv tshuab - Rau kev kho kom haum rau koj cov kev xav tau.

Kev vuam - Rau kev sib txuas flange lossis cov khoom siv sib txuas.

Cov Kev Pabcuam Txheej Txheem thiab Tiv Thaiv Kev Xeb - Muab kev tiv thaiv ntev raws li koj cov kev xav tau ib puag ncig.

Vim li cas thiaj xaiv Womic Steel?

Peev Xwm Tsim Khoom: Peb muaj cov chaw tsim khoom zoo tshaj plaws uas muaj peev xwm tsim tau ntau yam khoom.

Kev Paub Txog Kev Txawj NtsePeb pab neeg muaj cov engineers thiab cov kws tshaj lij uas mob siab rau kev tsim cov khoom zoo.

Qhov Zoo ntawm Kev Muab Khoom SivPeb muaj kev sib raug zoo nrog cov neeg muab khoom siv raw, ua kom xa khoom raws sijhawm thiab cov nqi zoo dua.

Cov Kev Xaiv Kho Kom HaumPeb muab cov kev daws teeb meem yooj ywm kom ua tau raws li cov kev xav tau tshwj xeeb ntawm cov haujlwm, suav nrog kev vuam, kev siv tshuab, thiab kev txheej.

Xaus lus

LubASTM A182 tus qauvua kom ntseeg tau tias cov khoom siv forged thiab dov steel muaj kev ntseeg siab thiab kev ua tau zoo hauv cov ntawv thov tseem ceeb. Womic Steel yog koj tus khub ntseeg siab rau cov khoom zoo tsim los ntawm tus qauv no, muab kev txhawb nqa dav dav los ntawm cov lus qhia txog kev siv tshuab mus rau kev xa khoom. Txawm hais tias koj xav tau qhov ntau thiab tsawg, vuam, lossis cov txheej txheem tshwj xeeb, peb muab cov kev daws teeb meem tshwj xeeb los ua kom tau raws li koj xav tau, ua kom muaj kev ua tau zoo tshaj plaws thiab kev xa khoom ntseeg tau.

Lub Vas Sab: www.womicsteel.com

Email: sales@womicsteel.com

Xov tooj/WhatsApp/WeChat: Victor: +86-15575100681 los yog Jack: +86-18390957568

Lub sijhawm tshaj tawm: Plaub Hlis-21-2025