1. Txheej txheem cej luam ntawm cov khoom

Womic Steel yog ib lub chaw tsim khoom uas ntseeg siab tau ntawm cov kav dej tooj liab zoo uas ua raws liASTM B88cov qauv, tshwj xeeb tshaj yog covHom Lkev qhia tshwj xeeb ua los ntawmC12200 (phosphorus-deoxidized, phosphorus seem ntau)tooj liab. Cov kav dej tooj liab no siv dav hauvcov kav dej, HVAC, kev tiv thaiv hluav taws, roj, thiab cov tshuab hluav taws xob dav davvim lawv txoj kev tiv thaiv corrosion zoo heev, durability, thiab formability.

C12200 tooj liab muaj feem pua siab ntawm tooj liab ntshiab thiab me ntsis phosphorus, ua rau nws weldability thiab tiv taus hydrogen embrittlement. Hom L kav dej sib npaug zoo ntawm phab ntsa tuab thiab qhov hnyav, muab kev ntseeg siab hauv ob qho tib si saum av thiab hauv av.

2. Ntau Yam Khoom

- Sab Nraud Txoj Kab uas hla (OD):6 hli txog 219 hli

- Phab ntsa tuab (WT):0.3 hli txog 10 hli

- Ntev:Tus qauv ntev ntawm3m, 5m, 6m, nrogqhov ntev uas hloov kho tau raws li qhov thov

- Cov raj xa dej:Muaj nyob rau hauv25m los yog 50m kaujrau kev teeb tsa yooj ywm hauv cov khoom siv hloov pauv cua sov

- Xaus tiav:Plain end, ntxuav thiab deburred; muaj nrog lossis tsis muaj lub hau

3. Kev Tawm Tsam Qhov Ntev (ASTM B88 C12200 Cov Raj Tooj Liab)

Womic Steel ua kom muaj qhov tseeb ntawm qhov ntev rauC12200cov raj xa dej ua raws liASTM B88cov qauv. Cov kev kam rau siab hauv qab no siv tau:

ASTM B88 - Rooj 1: Qhov Loj, Qhov Hnyav, thiab Kev kam rau siab rau Qhov Loj ntawm Cov Raj Dej Tooj Liab

| Qhov Loj Nominal (hauv.) | Sab Nraud Txoj Kab uas hla (hauv.) | Kev kam rau siab OD (Annealed) | OD Kev kam rau siab (Kos) | Hom K Phab Ntsa (hauv.) | Hom K Tol. (hauv.) | Hom L Phab Ntsa (hauv.) | Hom L Tol. (hauv.) | Hom M Phab Ntsa (hauv.) | Hom M Tol. (hauv.) |

| 1/4 | 0.375 | 0.002 | 0.001 | 0.035 | 0.0035 | 0.03 | 0.003 | C | C |

| 3/8 | 0.5 | 0.0025 | 0.001 | 0.049 | 0.005 | 0.035 | 0.004 | 0.025 | 0.002 |

| 1/2 | 0.625 | 0.0025 | 0.001 | 0.049 | 0.005 | 0.04 | 0.004 | 0.028 | 0.003 |

| 5/8 | 0.75 | 0.0025 | 0.001 | 0.049 | 0.005 | 0.042 | 0.004 | C | C |

| 3/4 | 0.875 | 0.003 | 0.001 | 0.065 | 0.006 | 0.045 | 0.004 | 0.032 | 0.003 |

| 1 | 1.125 | 0.0035 | 0.0015 | 0.065 | 0.006 | 0.05 | 0.005 | 0.035 | 0.004 |

| 1 1/4 | 1.375 | 0.004 | 0.0015 | 0.065 | 0.006 | 0.055 | 0.006 | 0.042 | 0.004 |

| 1 1/2 | 1.625 | 0.0045 | 0.002 | 0.072 | 0.007 | 0.06 | 0.006 | 0.049 | 0.005 |

| 2 | 2.125 | 0.005 | 0.002 | 0.083 | 0.008 | 0.07 | 0.007 | 0.058 | 0.006 |

| 2 1/2 | 2.625 | 0.005 | 0.002 | 0.095 | 0.01 | 0.08 | 0.008 | 0.065 | 0.006 |

| 3 | 3.125 | 0.005 | 0.002 | 0.109 | 0.011 | 0.09 | 0.009 | 0.072 | 0.007 |

| 3 1/2 | 3.625 | 0.005 | 0.002 | 0.12 | 0.012 | 0.1 | 0.01 | 0.083 | 0.008 |

| 4 | 4.125 | 0.005 | 0.002 | 0.134 | 0.013 | 0.11 | 0.011 | 0.095 | 0.01 |

| 5 | 5.125 | 0.005 | 0.002 | 0.160 | 0.016 | 0.125 | 0.012 | 0.109 | 0.011 |

| 6 | 6.125 | 0.005 | 0.002 | 0.192 | 0.019 | 0.14 | 0.014 | 0.122 | 0.012 |

| 8 | 8.125 | 0.008 | 0.002/-0.004 | 0.271 | 0.027 | 0.2 | 0.02 | 0.17 | 0.017 |

| 10 | 10.125 | 0.008 | 0.002/-0.006 | 0.338 | 0.034 | 0.25 | 0.025 | 0.212 | 0.021 |

| 12 | 12.125 | 0.008 | 0.002/-0.006 | 0.405 | 0.04 | 0.28 | 0.028 | 0.254 | 0.025 |

A Qhov nruab nrab ntawm txoj kab uas hla sab nraud ntawm lub raj yog qhov nruab nrab ntawm qhov siab tshaj plaws thiab qhov tsawg tshaj plaws ntawm txoj kab uas hla sab nraud, raws li txiav txim siab ntawm ib qho seem ntawm lub raj.

B Qhov siab tshaj plaws ntawm txhua qhov chaw.

C Qhia tias cov khoom siv tsis muaj feem ntau lossis tsis muaj kev kam rau siab tau tsim.

Cov kev kam rau siab no ua kom ntseeg tau tias cov raj xa dej ua tau raws likev xav tau siab thiab zoo, ua rau lawv haum rauCov ntawv thov kev lag luam thiab kev siv dej hiav txwv uas xav tau ntau.

3. Cov Tshuaj Lom Zem (C12200 - ASTM B88)

Khoom Cov khoom sib xyaw (% los ntawm qhov hnyav)

Tooj liab (Cu) MinB≥ 99.9 (xws li nyiaj)

Phosphorus (P) 0.015 – 0.040

Cov pa oxygen yuav tsum yog 10 ppm siab tshaj.

B Tooj Liab + Nyiaj ≤ 0.04

Cov phosphorus ua rau weldability thiab tiv taus kev tawg ntawm kev ntxhov siab, thaum tswj tau qhov kub thiab hluav taws xob conductivity siab.

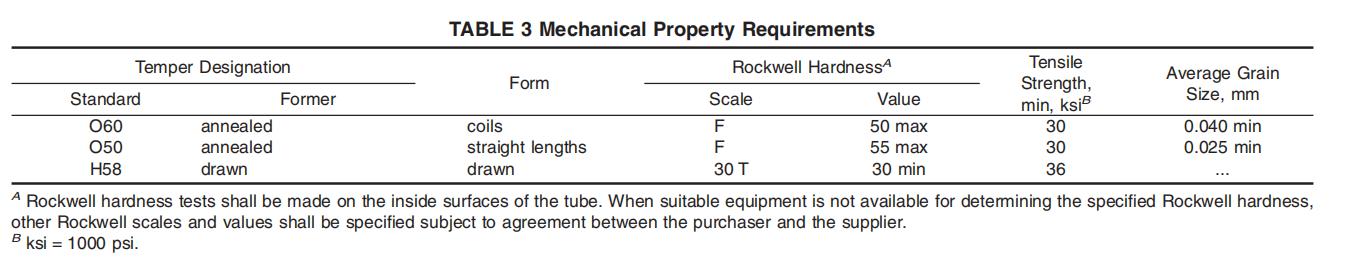

4. Cov Khoom Siv Kho Tshuab

Cov yeeb nkab tooj liab hom L feem ntau yog muab los ntawm cov kav dej tawv (kos), tsim nyog rau cov tshuab siab thiab kev teeb tsa ncaj.

5. Cov Cai Xa Khoom

Womic Steel xa cov kav dej tooj liab Hom L hauv cov xwm txheej hauv qab no:

Kub tawv (H58):Cov qhov ntev ncaj rau cov tshuab siab

Kub hnyiab (O60):Muaj raws li qhov kev thov rau cov ntawv thov uas xav tau kev khoov thiab kev tsim

6. Txheej Txheem Tsim Khoom

Womic Steel ua kom muaj kev raug siab thiab zoo los ntawm cov kauj ruam hauv qab no:

- Melting & Casting:Tooj liab uas muaj purity siab raug yaj thiab pov rau hauv cov billets.

- Kev rho tawm:Cov billets raug extruded rau hauv tubular daim ntawv.

- Kev Kos Duab Txias:Cov hlab ntsha raug rub mus rau qhov loj thiab tuab kawg.

- Kev Kub Hnyiab (xaiv tau):Yog tias xav tau, kho cua sov rau qhov kub mos.

- Kev Ncaj Ncees & Kev Txiav:Cov kav dej raug txiav rau qhov ntev tus qauv lossis kev cai.

- Kev Ntxuav thiab Kev Tshuaj Xyuas:Cov chaw sab hauv thiab sab nraud raug ntxuav thiab kuaj xyuas.

- Kev Cim & Ntim Khoom:Cov kav dej tau cim nrog ASTM B88, hom, thiab qhov loj me rau kev taug qab.

7. Kev Ntsuas & Kev Tshuaj Xyuas

Womic Steel ua kom muaj cov qauv zoo tshaj plaws los ntawm kev uakev kuaj xyuas thiab kev tshuaj xyuas nruj, suav nrog:

- Kev Tshuaj Xyuas Txog Cov Tshuaj Lom Zem:Kev txheeb xyuas siv cov tshuaj spectrographic lossis cov tshuaj ntub dej

- Kev Ntsuas Tensile:Xyuas kom lub zog thiab elongation ua tau raws li ASTM B88 cov cai

- Kev Ntsuas Qhov Nyuaj:Ntsuas siv covTxoj kev Vickers

- Kev Ntsuas Kev Nthuav Dav:Kev nthuav dav ntawm qhov kawg ntawm lub raj los ntawm30%siv ib qho45 ° conical mandrel

- Kev Ntsuas Kev Sib Nraus:Kev ntsuam xyuas ntawmdeformability thiab tsis kam rau cracking

- Kev Ntsuas Tam Sim No Eddy (ECT):Kev kuaj pom ntawmqhov tsis zoo ntawm qhov chaw thiab hauv qab

- Kev Ntsuas Siab Hydrostatic:Xyuas kom cov raj muaj zoglub siab sab hauv tsis muaj qhov xau

8. Kev kuaj qauv

Kev kuaj thiab kuaj xyuas yog ua raws li ASTM B88 thiab cov txheej txheem QA sab hauv. Cov qauv kuaj raug xaiv los ntawm txhua pawg rau:

l Cov ntsiab lus tshuaj lom neeg

l Cov khoom siv kho tshuab

l Qhov tseeb ntawm qhov ntev

l Qhov chaw mob

9. Ntim Khoom

Yuav kom paub tseeb tiaskev tuav pov hwm thiab kev thauj mus los kom muaj kev nyab xeeb, Womic Steel muabkev daws teeb meem ntim khoom ruaj khov, suav nrog:

- Txheej Txheem Tiv Thaiv Oxidation:Txheej tiv thaiv tau siv los tiv thaiv xeb thaum lub sijhawm khaws cia thiab thauj mus los

- Cov hau kawg:Cov yas lossis hlau hau ntawm cov kav dej kom tiv thaiv kev ua qias tuaj

- Kev Muab Ua Ib Pawg:Siv cov yas los yog hlau los khi kom ruaj khov

- Ntoo Crate:Ntim rau hauvcov ntoo uas tsis ntub dejnrog cov ua npuas ncauj tiv thaiv

- Kev Sau Npe:Txhua pob khoom muaj daim ntawv lo nrogOD, WT, ntev, temper, batch number, thiab hnub tsim khoom

10. Kev Thauj Mus Los & Kev Xa Khoom

Womic Steel ua kom ntseeg tau tiaskev xa khoom raws sijhawm thiab ruaj ntseglos ntawm:

- Kev Thauj Khoom Hiav Txwv:Ruaj ntsegKev xa khoom hauv thawv rau kev faib khoom thoob ntiaj teb

- Kev Thauj Mus Los Ntawm Tsheb Ciav Hlau & Kev:Kev xa khoom txhim khu kev qha rau cov neeg siv khoom hauv cheeb tsam

- Kev Tswj Xyuas Tshwj Xeeb:Cov kev xaiv tswj huab cua rau cov ntawv thov rhiab heev

- Cov Ntaub Ntawv Qhia Txog:Xws liDaim Ntawv Pov Thawj Kev Xeem Zeb (MTC), Cov Ntawv Qhia Txog Kev Ua Raws Cai ntawm Cov Khoom Siv, thiab Kev Pov Hwm

- Kev Tiv Thaiv Kev Kub Ntxhov Zoo Tshaj Plaws:Zoo heev raumarine, tshuaj lom neeg, thiab kev siv cua sov hloov pauv

- Kev Tsim Khoom Zoo:Nruj heevkev kam rau siab ntawm qhov ntevrau kev ua tau zoo tshaj plaws

- Kev daws teeb meem tshwj xeeb:Cov qhov loj me, cov xim kub, thiab cov txheej txheem kom ua tau raws li cov kev xav tau tshwj xeeb

- Kev Ntsuas Kom Paub Ntau Yam:Xyuas kom ua raws li tag nrhoASTM B88

- Kev Sib Txuas Lus Thoob Ntiaj Teb:Kev xa khoom thoob ntiaj teb sai thiab txhim khu kev qha

11. Cov txiaj ntsig ntawm kev xaiv Womic Steel

12. Cov Ntawv Thov

Peb liASTM B88 C12200Cov raj xa dej zoo tagnrho rau:

- Kev Lag Luam Hiav Txwv: Cov condenser txias los ntawm dej hiav txwv, cov kav dej, thiab cov khoom sib pauv cua sov hauv nkoj

- Cov Chaw Fais Fab:Cov pa condenser thiabcov tshuab cua txias

- Cov Nroj Tsuag Desalination:Cov kav dej uas tiv taus xeb rau cov dej ntsev

- Kev Ua Tshuaj:Cov raj xa dej kub siab, kub siab

- HVAC & Tub Yees: Cov kauj cua txias thiab cov tshuab cua txias hauv kev lag luam

Xaus lus

Womic Steel cov kav dej tooj liab ASTM B88 C12200 Hom L muaj kev ua tau zoo heev, ruaj khov, thiab tiv taus xeb, ua rau lawv yog qhov kev xaiv zoo tshaj plaws rau ntau yam kav dej. Nrog kev ua raws li cov qauv ASTM thiab kev lees paub zoo tag nrho, peb xyuas kom meej tias txhua qhov kev xa khoom ua tau raws li qhov kev cia siab siab tshaj plaws hauv kev ua haujlwm thiab kev ntseeg siab.

Peb txaus siab rau peb tus kheejkev pabcuam kho kom haum, cov voj voog tsim khoom sai, thiabkev xa khoom thoob ntiaj teb, xyuas kom meej tias koj cov kev xav tau tshwj xeeb tau raug ua tiav nrog kev ua tib zoo thiab kev ua tau zoo.

Lub Vas Sab: www.womicsteel.com

Email: sales@womicsteel.com

Xov tooj/WhatsApp/WeChat: Victor: +86-15575100681 los yog Jack: +86-18390957568

Lub sijhawm tshaj tawm: Lub Ib Hlis-21-2026