Womic Steel tshwj xeeb hauv kev tsim cov kav hlau zoo uas ua raws liDIN 2391cov qauv. Peb cov kav dej yog tsim los rau ntau yam kev siv, suav nrog cov qauv, tshuab, thiab cov txheej txheem thauj mus los. Siv cov thev naus laus zis tsim khoom siab heev thiab cov txheej txheem tswj xyuas zoo, peb xyuas kom meej tias peb cov khoom ua tau raws li cov qauv thoob ntiaj teb, muab kev ruaj khov, kev ua haujlwm raug, thiab kev ua tau zoo tsis sib xws.

Peb cov kav hlau yog qhov tsim nyog rau kev siv rau hauv idlers, hydraulic thiab pneumatic cylinders, mechanical thiab automotive engineering, machinery, roj cylinder raj, maus taus shock absorber steel raj, thiab auto shock absorber sab hauv lub tog raj kheej. Cov ntawv thov no xav tau cov kav hlau muaj zog, precision-engineered uas muaj kev ntseeg siab thiab kev ua tau zoo hauv cov chaw nyuaj.

DIN 2391 Cov Hlab Ntswg Tsis Muaj Qhov Txuas Ntau Yam Khoom:

- Sab Nraud Txoj Kab uas hla (OD): 6 hli txog 400 hli

- Phab ntsa tuab (WT): 1 hli txog 18 hli

- Ntev: Muaj qhov ntev raws li qhov xav tau, feem ntau yog txij li 6 meters txog 12 meters, nyob ntawm seb qhov project xav tau dab tsi.

DIN 2391 Cov Hlab Ntswg Tsis Muaj Qhov Txuas Kev kam rau siab:

| Cov Qauv | Kev kam rau siab |

| Sab Nraud Txoj Kab uas hla (OD) | ± 0.01 hli |

| Phab ntsa tuab (WT) | ± 0.1 hli ntawm qhov tuab ntawm phab ntsa uas tau teev tseg |

| Ovality (Qib Oval) | 0.1 hli |

| Ntev | ± 5 hli |

| Kev Ncaj Ncees | Maximum 1 hli ib 'meter' |

| Qhov Chaw Tiav | Raws li cov neeg siv khoom qhia (Feem ntau: Roj tiv thaiv xeb, Chrome plating nyuaj, Nickel chromium plating, lossis lwm yam txheej) |

| Kev Sib Npaug ntawm Qhov Kawg | ± 1° |

DIN 2391 Cov Hlab Ntswg Tsis Muaj Qhov Txuas Cov Tshuaj Lom Zem

| Tus Qauv | Qib | Cov Cheebtsam Tshuaj (%) | |||||

| Lub Cim | Khoom siv tsis muaj. | C | Si | Mn | P | S | |

| DIN2391 | St 30 Si | 1.0211 | ≤0.10 | ≤0.30 | ≤0.55 | ≤0.025 | ≤0.025 |

| St 30 Al | 1.0212 | ≤0.10 | ≤0.05 | ≤0.55 | ≤0.025 | ≤0.025 | |

| Txoj Kev 35 | 1.0308 | ≤0.17 | ≤0.35 | ≥0.40 | ≤0.025 | ≤0.025 | |

| Txoj Kev 5 | 1.0408 | ≤0.21 | ≤0.35 | ≥0.40 | ≤0.025 | ≤0.025 | |

| Txoj Kev 52 | 1.058 | ≤0.22 | ≤0.55 | ≤1.60 | ≤0.025 | ≤0.025 | |

Cov ntsiab lus alloying hauv qab no yuav raug ntxiv: Nb: ≤ 0,03%; Ti: ≤ 0,03%; V: ≤ 0,05%; Nb + Ti + V: ≤ 0,05%

DIN 2391 Cov Hlab Ntswg Tsis Muaj Qhov Txuas Cov Cai Xa Khoom

Cov raj yuav tsum tau tsim los ntawm cov txheej txheem rub txias lossis dov txias. Cov raj yuav tsum tau muab rau hauv ib qho ntawm cov xwm txheej xa khoom raws li hauv qab no:

| Lub Npe | Lub Cim | Kev piav qhia |

| Txias tiav lawm (nyuaj) | BK | Cov raj tsis raug kho cua sov tom qab qhov kawg txias tsim thiab yog li, muaj kev tiv thaiv siab rau deformation. |

| Txias tiav lawm (mos) | BKW | Kev kho cua sov kawg yog ua raws li kev kos duab txias uas muaj kev hloov pauv tsawg. Kev ua tiav ntxiv kom tsim nyog tso cai rau qee qib ntawm kev tsim txias (piv txwv li khoov, nthuav dav). |

| Txias tiav lawm thiab txo kev ntxhov siab | BKS | Kev kho cua sov yog siv tom qab cov txheej txheem tsim khoom txias kawg. Nyob rau hauv cov xwm txheej ua haujlwm tsim nyog, qhov nce ntawm cov kev ntxhov siab seem uas koom nrog ua rau ob qho tib si tsim thiab ua haujlwm rau qee qib. |

| Annealed | GBK | Cov txheej txheem tsim txias kawg yog ua raws li kev annealing hauv huab cua tswj tau. |

| Ua kom zoo li qub | NBK | Cov txheej txheem tsim txias kawg yog ua raws li kev annealing saum toj no qhov chaw hloov pauv sab saud hauv huab cua tswj hwm. |

DIN 2391 Cov Hlab Ntswg Tsis Muaj Qhov Txuas Cov Khoom Siv Kho Tshuab.

| Cov khoom siv kho tshuab ntawm chav tsev kub | |||||||||||||

| Qib Hlau | Tus nqi tsawg kawg nkaus rau qhov xwm txheej xa khoom | ||||||||||||

| Lub Npe Hlau | Tus lej hlau | BK | BKW | BKS | GBK | NBK | |||||||

| Rm | Ib % | Rm | Ib % | Rm | ReH | Ib % | Rm | Ib % | Rm | ReH | Ib % | ||

| Mpa | Mpa | Mpa | Mpa | Mpa | Mpa | Mpa | |||||||

| St 30 Si | 1.0211 | 430 | 8 | 380 | 12 | 380 | 280 | 16 | 280 | 30 | 290 txog 420 | 215 | 30 |

| St 30 Al | 1.0212 | 430 | 8 | 380 | 12 | 380 | 280 | 16 | 280 | 30 | 290 txog 420 | 215 | 30 |

| Txoj Kev 35 | 1.0308 | 480 | 6 | 420 | 10 | 420 | 315 | 14 | 315 | 25 | 340 txog 470 | 235 | 25 |

| Txoj Kev 45 | 1.0408 | 580 | 5 | 520 | 8 | 520 | 375 | 12 | 390 | 21 | 440 txog 570 | 255 | 21 |

| Txoj Kev 52 | 1.0580 | 640 | 4 | 580 | 7 | 580 | 420 | 10 | 490 | 22 | 490 txog 630 | 355 | 22 |

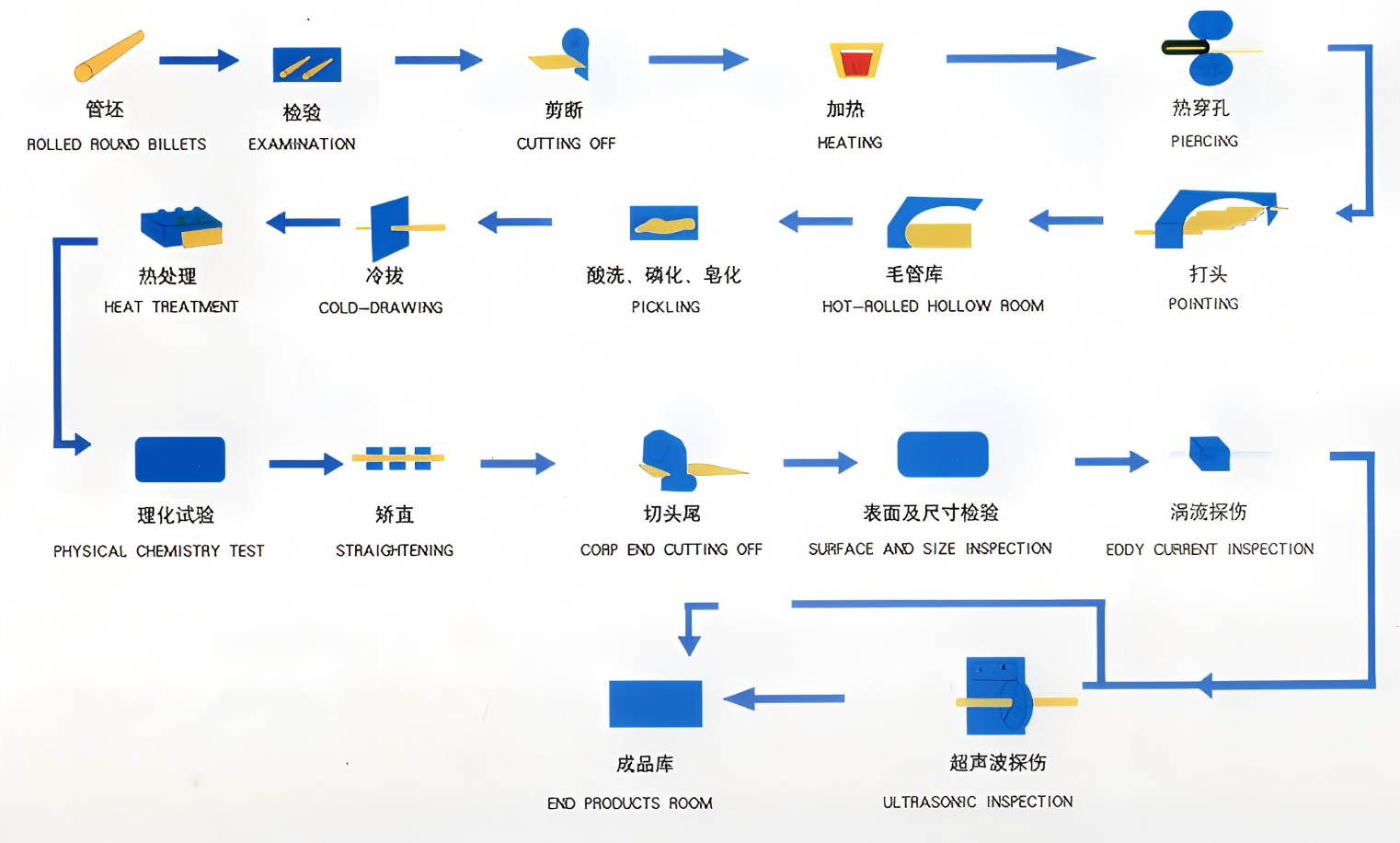

DIN 2391 Cov Hlab Ntswg Tsis Muaj Qhov Txuas Cov Txheej Txheem Tsim Khoom:

● Cov Ntawv Sib Dhos: Kev tsim khoom pib nrog kev siv cov billets dov puag ncig, uas yog cov khoom siv raw thawj zaug hauv daim ntawv ntawm cov pas nrig hlau.

●Kev kuaj mob: Cov billets no raug kuaj xyuas ua ntej seb puas zoo thiab sib xws kom paub tseeb tias lawv ua tau raws li cov qauv tsim nyog ua ntej mus rau kauj ruam tom ntej.

●Txiav Tawm: Cov billets ces raug txiav mus rau qhov ntev xav tau kom haum rau qhov yuav tsum tau ua ntxiv.

●Kev ua cua sovCov billets txiav raug cua sov rau qhov kub siab kom ua rau lawv tsim nyog rau kev hloov pauv ntxiv hauv cov kauj ruam tom ntej.

●Kev tho qhov: Cov billets uas tau cua sov ces raug tho kom tsim tau ib lub hollow center, uas tsim cov qauv yooj yim ntawm cov yeeb nkab seamless.

●Chav Kub-Dov Hollow: Cov billets hollow raug kub-dov kom ua rau cov yeeb nkab zoo dua.

●Kos duab txias: Cov kav dej kub dov ces raug rub los ntawm lub pwm nyob rau hauv kev tswj hwm tej yam kev mob, txo qhov txoj kab uas hla thiab tuab, thiab txhim kho qhov loj ntawm cov kav dej.

●Kev ua kua txobCov kav dej raug muab tso rau hauv cov kua qaub kom tshem tawm cov nplai saum npoo lossis cov khoom tsis huv uas tsim thaum lub sijhawm tsim khoom.

●Kev Kho Mob KubCov kav dej raug kho cua sov, uas suav nrog cov txheej txheem zoo li annealing los txhim kho lawv cov khoom siv kho tshuab thiab txo kev ntxhov siab.

●Kev Ntsuas Tshuaj Lom ZemCov kav dej raug kuaj lub cev thiab tshuaj lom neeg kom paub tseeb tias lawv ua tau raws li cov lus qhia thiab cov khoom siv uas xav tau.

●Kev ncajTom qab kev kho cua sov, cov kav dej raug ncaj kom ntseeg tau tias lawv sib xws thiab raug.

●Kev Txiav Qhov Kawg ntawm Coil: Qhov kawg ntawm cov kav dej raug txiav kom raws li qhov ntev uas xav tau.

●Kev Tshuaj Xyuas Qhov Nto thiab Qhov LojCov kav dej raug tshuaj xyuas kom zoo rau qhov tsis zoo ntawm qhov chaw thiab kuaj xyuas qhov tseeb ntawm qhov ntev kom ntseeg tau tias zoo.

●Kev Tshuaj Xyuas Tam Sim No Eddy: Qhov kev sim tsis ua puas tsuaj no yog siv los nrhiav cov kab nrib pleb lossis qhov tsis zoo ntawm qhov chaw uas tej zaum yuav tsis pom rau lub qhov muag liab qab.

●Kev Tshuaj Xyuas UltrasonicCov kav dej raug kuaj xyuas los ntawm ultrasonic kom paub txog tej qhov tsis zoo sab hauv lossis qhov tsis zoo uas yuav cuam tshuam rau lub zog lossis kev ncaj ncees ntawm cov kav dej.

●Chav Khoom KawgThaum kawg, cov kav dej tiav lawm raug xa mus rau chav khoom kawg, qhov chaw uas lawv tau ntim thiab npaj rau kev xa khoom.

Kev Ntsuas & Kev Tshuaj Xyuas:

Womic Steel lav tag nrho kev taug qab thiab kev ruaj ntseg zoo rau allDIN 2391 Seamless Precision Tubes los ntawm cov kev xeem hauv qab no:

- Kev Tshuaj Xyuas Qhov NtevKev Ntsuas ntawm OD, WT, ntev, ovality, thiab ncaj.

- Kev Ntsuas Tshuab:

- Kev Ntsuas Tensile

- Kev Ntsuas Kev Cuam Tshuam

- Kev Ntsuas Qhov Nyuaj

- Kev Ntsuas Tsis Ua Rau Puas Tsuaj (NDT):

- Eddy Current Test rau cov teeb meem sab hauv

- Kev Ntsuas Ultrasonic (UT) rau phab ntsa tuab thiab kev ncaj ncees

- Kev Tshuaj Xyuas Tshuaj: Ua los xyuas cov khoom siv sib xyaw siv cov txheej txheem spectrographic.

- Kev Ntsuas Hydrostatic: Txhawm rau xyuas seb lub yeeb nkab puas muaj peev xwm tiv taus qhov siab sab hauv yam tsis muaj kev puas tsuaj.

Chaw Kuaj Mob & Kev Tswj Xyuas Zoo:

Womic Steel ua haujlwm hauv chav kuaj mob uas muaj cov khoom siv kuaj thiab tshuaj xyuas zoo heev kom ntseeg tau tias ua raws li DIN 2391 Seamless Precision Tubes cov qauv. Peb cov kws tshaj lij ua qhov kev kuaj xyuas zoo hauv tsev rau txhua pawg ntawm cov kav dej. Peb kuj ua haujlwm nrog cov koom haum ywj pheej sab nraud rau kev txheeb xyuas sab nraud ntawm cov kav dej zoo.

Ntim Khoom

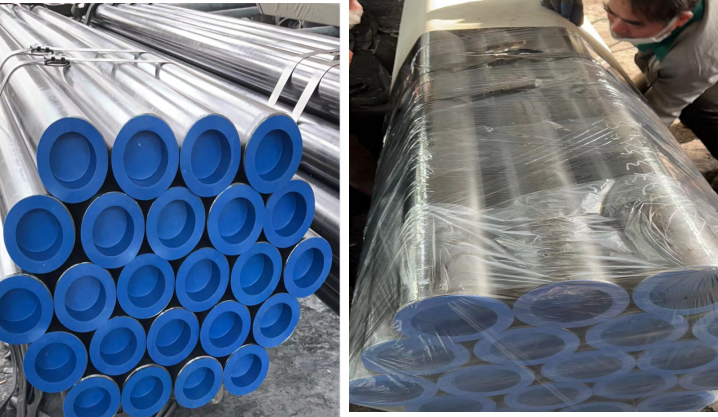

Kev Tiv Thaiv TxheejTxhua lub raj xa dej raug ntxuav thiab coated nrog ib txheej tiv thaiv xeb kom tiv thaiv oxidation lossis xeb thaum lub sijhawm thauj mus los thiab khaws cia. Qhov no yuav suav nrog ib txheej roj, quav ciab, lossis lwm yam txheej tiv thaiv raws li cov neeg siv khoom xav tau.

Cov hau kawg: Ob qho kawg ntawm cov raj xa dej raug kaw nrog cov yas lossis hlau kawg lub hau kom tiv thaiv cov av, dej noo, thiab kev puas tsuaj thaum lub sijhawm tuav thiab thauj mus los.

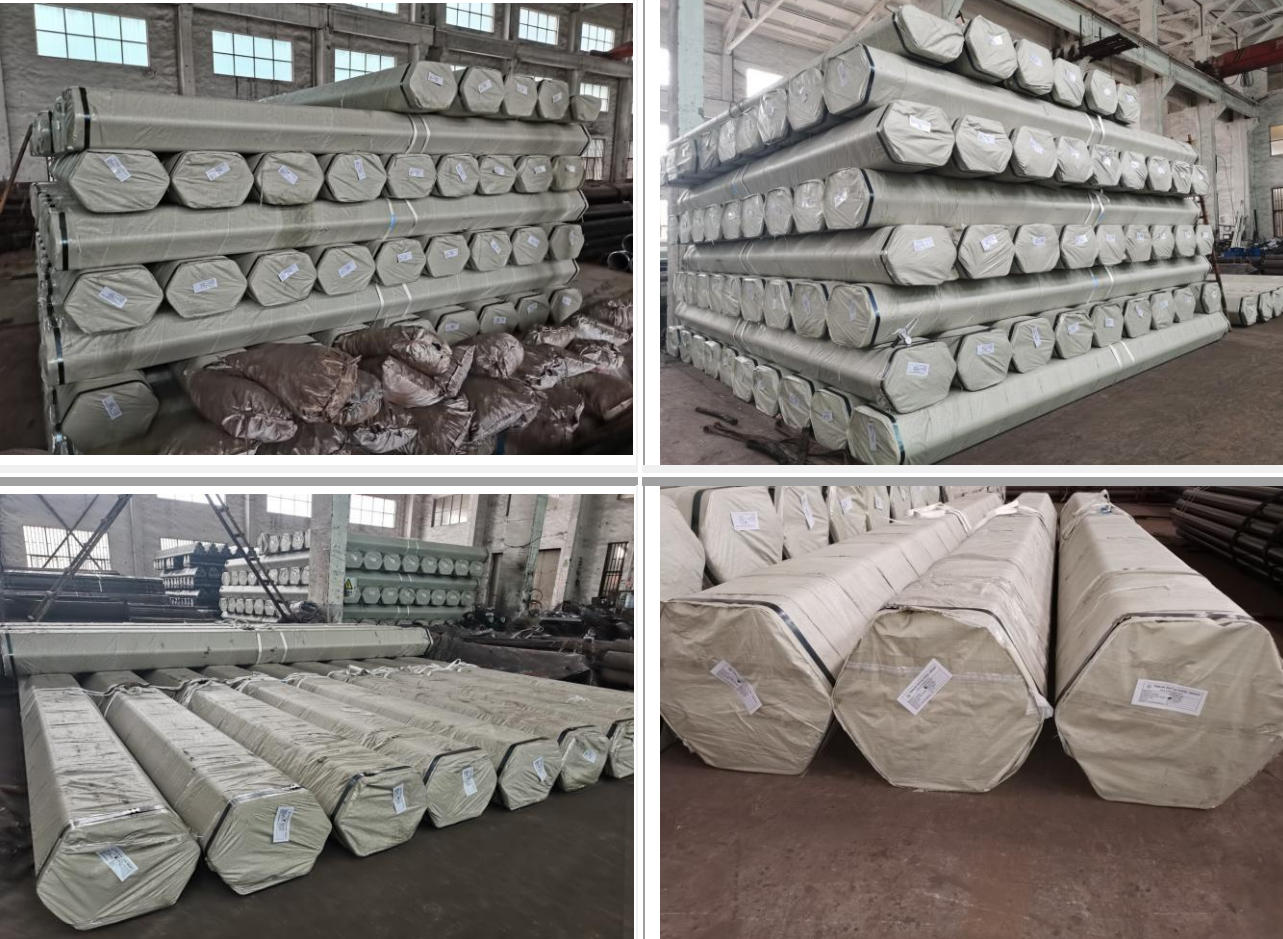

Kev muab ua keCov raj xa dej raug muab ntim rau hauv cov pob khoom uas yooj yim tswj tau, feem ntau yog qhov ntev uas sib haum nrog cov qauv kev xa khoom. Cov pob khoom raug qhwv nrog cov hlua hlau, cov hlua yas, lossis cov hlua khi kom tuav lawv ua ke kom ruaj ntseg.

Kev tiv thaiv ntawm cov rajYuav kom tsis txhob muaj kev sib chwv ncaj qha thiab tiv thaiv kev khawb lossis kev puas tsuaj, cov raj hauv cov pob khoom feem ntau raug cais los ntawm cov khoom siv tiv thaiv xws li cov ntawv cardboard, cov ntoo spacers, lossis cov ntawv ua npuas ncauj.

Cov Khoom Siv Ntim KhoomCov pob ntawm cov raj feem ntau yog qhwv rau hauv cov ntaub qhwv lossis cov yas yas hnyav kom ntseeg tau tias lawv tseem nyob ruaj khov thaum lub sijhawm thauj mus los thiab tiv thaiv los ntawm hmoov av thiab dej noo.

Kev Txheeb Xyuas thiab Kev Sau NpeTxhua pob khoom muaj cim qhia meej txog cov khoom, suav nrog qib hlau, qhov loj (txoj kab uas hla, tuab, ntev), ntau npaum li cas, tus lej ua khoom, thiab lwm yam kev qhia tshwj xeeb. Cov ntawv lo yuav muaj cov lus qhia txog kev tuav xws li "Khaws Kom Qhuav" lossis "Ua Zoo."

Kev Thauj Mus Los

Hom Kev Thauj Mus Los:

Kev Thauj Khoom Hiav TxwvRau kev xa khoom thoob ntiaj teb, cov raj xa dej uas tsis muaj qhov sib txuas feem ntau raug xa los ntawm hiav txwv. Cov pob khoom raug thauj mus rau hauv cov thawv xa khoom lossis rau ntawm cov khib tiaj tus, nyob ntawm qhov loj me thiab ntev ntawm cov raj.

Kev Thauj Mus Los Ntawm Tsheb Ciav Hlau Los Yog Kev LojRau kev xa khoom hauv tsev lossis hauv cheeb tsam, cov raj xa khoom tuaj yeem thauj los ntawm kev tsheb ciav hlau lossis txoj kev, thauj mus rau ntawm cov tsheb thauj khoom tiaj tus lossis hauv cov thawv.

Kev Thauj Khoom thiab Kev Ruaj NtsegThaum thauj khoom rau ntawm cov tsheb thauj khoom, cov pob khoom raug khi kom ruaj khov kom tiv thaiv kev txav mus los lossis kev txav mus los thaum lub sijhawm thauj mus los. Qhov no tuaj yeem ua tiav los ntawm kev siv cov hlua hlau, cov hlua yas, thiab cov khoom siv ntxiv hauv lub thawv lossis lub tsheb thauj khoom. Rau kev thauj khoom hauv hiav txwv, yog tias cov raj tsis nyob hauv lub thawv, lawv feem ntau raug thauj mus rau ntawm cov khib tiaj tus thiab ruaj ntseg nrog cov ntaub thaiv lossis cov npog ntxiv los tiv thaiv lawv ntawm huab cua xws li nag lossis dej ntsev.

Kev Tswj Huab CuaYog tias xav tau (tshwj xeeb tshaj yog nyob rau hauv thaj chaw noo noo lossis ntug dej hiav txwv), kev tswj hwm kev thauj mus los (piv txwv li, kev tswj qhov kub thiab av noo) tuaj yeem npaj tau los tiv thaiv kev puas tsuaj los ntawm cov yam ntxwv ib puag ncig thaum lub sijhawm thauj mus los.

Cov ntaub ntawv pov thawjCov ntaub ntawv xa khoom raug npaj rau kev tshem tawm kev lis kev cai thiab kev taug qab kev thauj mus los, suav nrog daim ntawv pov thawj xa khoom, daim ntawv pov thawj keeb kwm, daim ntawv pov thawj zoo, thiab lwm yam ntaub ntawv tswj hwm tsim nyog.

Kev Pov HwmYuav kom tiv thaiv tau kev puas tsuaj, kev poob, lossis kev tub sab thaum lub sijhawm thauj mus los, nws raug pom zoo kom npaj kev pov hwm rau cov khoom xa tuaj, tshwj xeeb tshaj yog rau cov khoom xa tuaj thoob ntiaj teb.

Cov txiaj ntsig ntawm kev xaiv Womic Steel:

- Kev Tsim Khoom ZooPeb cov txheej txheem tsim khoom zoo tshaj plaws tso cai rau peb ua kom tau raws li qhov kev kam rau siab tshaj plaws rau txoj kab uas hla, phab ntsa tuab, thiab ovality.

- Cov Khoom Siv ZooPeb tsuas yog nrhiav cov hlau zoo tshaj plaws los ntawm cov neeg muag khoom uas ntseeg siab tau, kom ntseeg tau tias muaj cov khoom siv kho tshuab zoo heev thiab tiv taus xeb.

- Kev Kho Kom HaumPeb muab cov kev daws teeb meem raws li cov neeg siv khoom xav tau, suav nrog qhov ntev tshwj xeeb, kev kho qhov chaw, thiab cov kev xaiv ntim khoom.

- Kev Ntsuas Txhua YamNrog peb cov txheej txheem kuaj xyuas nruj, peb xyuas kom meej tias txhua lub yeeb nkab ua tau raws li txhua yam kev cai thiab kev cai lij choj, xa cov kev ua tau zoo txhim khu kev qha thiab ruaj khov.

- Pab Pawg Neeg Paub Txog: Peb pab neeg ntawm cov engineers thiab cov kws kho tshuab muaj kev txawj ntse thiab kev paub ntau, ua kom ntseeg tau tias cov qauv siab tshaj plaws hauv kev tsim khoom thiab kev pabcuam rau cov neeg siv khoom.

- Kev Xa Khoom Raws SijhawmPeb ua haujlwm nrog lub network logistics txhim khu kev qha, xyuas kom meej tias cov khoom xa tuaj raws sijhawm rau txhua qhov chaw ntawm lub ntiaj teb.

Xaus lus:

Womic Steel's DIN 2391 Seamless Precision Tubes yog cov lus sib xws nrog kev ua tau zoo, kev ruaj khov, thiab kev tsim khoom meej. Peb txoj kev cog lus rau qhov zoo thiab kev txaus siab ntawm cov neeg siv khoom ua rau peb sib txawv ua tus thawj coj hauv kev tsim cov yeeb nkab hlau. Txawm hais tias rau kev tsim kho, tshuab, lossis cov kua dej, peb cov khoom tau tsim los ua kom tau raws li cov qauv siab tshaj plaws ntawm kev ntseeg siab thiab lub zog.

Xaiv Womic Steel Group ua koj tus khub txhim khu kev qha rau cov kav dej Stainless Steel zoo thiab cov khoom siv thiab kev ua haujlwm xa khoom tsis zoo. Txais tos nug!

Lub Vas Sab: www.womicsteel.com

Email: sales@womicsteel.com

Xov tooj/WhatsApp/WeChat: Victor: +86-15575100681 los yog Jack: +86-18390957568

Lub sijhawm tshaj tawm: Lub Ob Hlis-02-2025