1.Txheej Txheem Cej Luam Khoom

Womic Steel tshwj xeeb hauv kev tsim cov raj tooj liab zoo uas ua raws li tus qauv EN 1057. Cov raj no yog ua los ntawm Cu-DHP (CW024A) cov khoom siv, ua kom muaj kev ntshiab thiab kev ua tau zoo rau kev siv dej, kev faib roj, cua sov, thiab kev siv txias. Nrog rau cov ntsiab lus tooj liab thiab nyiaj tsawg kawg nkaus ntawm 99.9% thiab cov phosphorus tswj tau ntawm 0.015% thiab 0.040%, peb cov raj tooj liab qhia txog kev tiv thaiv corrosion zoo heev, ruaj khov, thiab yooj yim rau kev teeb tsa.

Cov raj tooj liab EN 1057 yog tsim los siv rau hauv ob qho tib si hauv tsev thiab kev lag luam, muab kev ua tau zoo hauv cov dej haus, cua sov hauv nruab nrab, tub yees, thiab cov kav dej roj kho mob. Tsim los ntawm cov qauv zoo, cov raj no muaj cov khoom siv kho tshuab zoo heev thiab kev ntseeg siab rau kev pabcuam mus sij hawm ntev.

2.EN 1057 Copper Tubes Ntau Lawm Ntau Yam

●Txoj kab uas hla sab nraud (OD):6 hli txog 267 hli

●Phab ntsa tuab (WT):0.3hli rau20hli

●Ntev:Qhov ntev txheem ntawm 3m, 5m, lossis 6m; kev cai ntev muaj thaum thov

●Cov raj xa dej:Muaj nyob rau hauv 25m lossis 50m coils rau kev teeb tsa yooj ywm

3.EN 1057 Copper Tubes kam rau ua

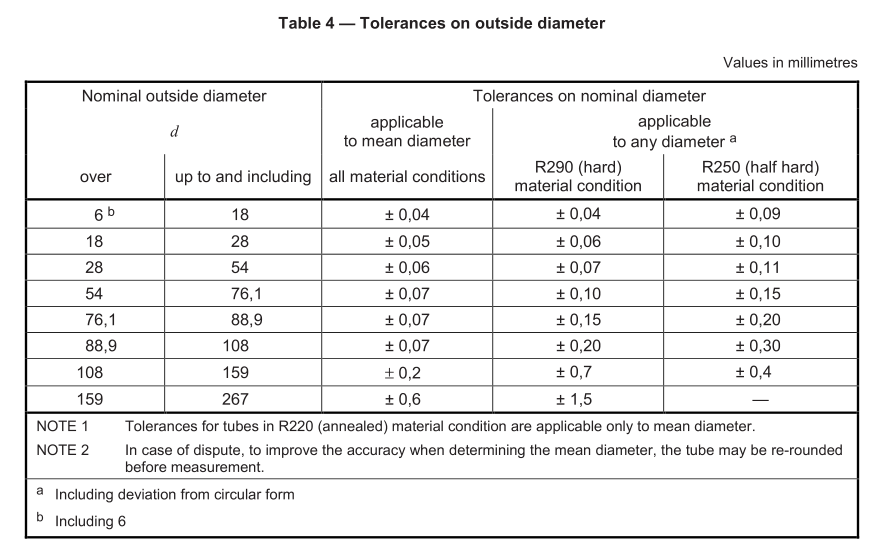

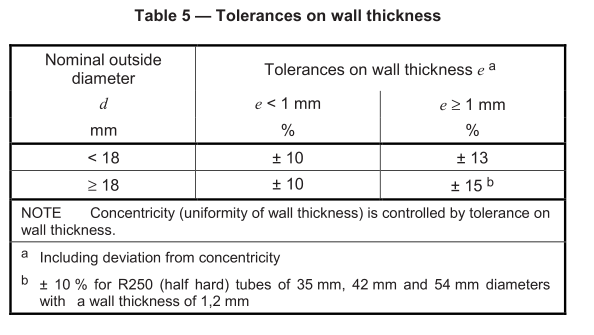

Womic Steel ua kom muaj qhov tseeb ntawm qhov ntev nrog cov kev kam rau siab hauv qab no:

4.EN 1057 Cov Raj Tooj Liab

Peb cov raj tooj liab yog tsim los ntawm Cu-DHP (CW024A) cov khoom siv nrog cov hauv qab no:

Cov khoom xyaw yuav tsum ua raws li cov cai hauv qab no:

Cu + Ag: tsawg kawg 99,90%;

0,015% ≤P ≤0,040%.

Qib tooj liab no yog xaiv los ntawm Cu-DHP lossis CW024A.

Cov khoom sib xyaw no ua kom muaj kev tiv thaiv corrosion zoo heev, thermal thiab electrical conductivity siab, thiab ua haujlwm tau zoo dua.

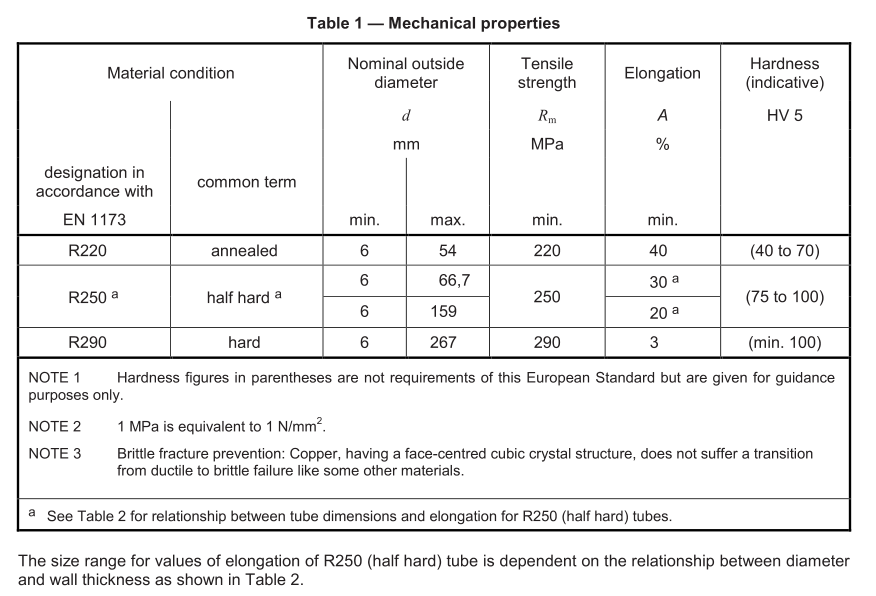

5.EN 1057 Cov Tub Ntxhais Tooj Liab Cov Khoom Siv Kho Tshuab

Cov khoom siv kho tshuab ntawm peb cov raj tooj liab EN 1057 nyob ntawm seb tus neeg xa khoom mob li cas:

6.EN 1057 Cov Kev Cai Xa Khoom Rau Cov Raj Tooj Liab

Womic Steel muab EN 1057 tooj liab raj hauv cov tempers hauv qab no:

●R220 (Annealed): Yooj yim heev, tsim nyog rau kev khoov thiab tsim

●R250 (Ib Nrab-Tawv): Lub zog nruab nrab, qhov sib npaug zoo ntawm kev ywj pheej thiab kev ruaj khov

●R290 (Tawv): Muaj zog heev, tsim rau kev siv ncaj nraim nrog kev khoov tsawg kawg nkaus

7.EN 1057 Cov Txheej Txheem Tsim Khoom Siv Tooj Liab

Peb cov txheej txheem tsim khoom siab heev ua kom ntseeg tau tias cov qauv zoo tshaj plaws:

1. Kev Npaj Casting & Billet: Cov tooj liab uas muaj purity siab yog yaj thiab pov rau hauv cov billets.

2. Extrusion & Piercing: Billets raug extruded rau hauv daim ntawv raj thiab pierced rau qhov loj me xav tau.

3. Kev Kos Duab Txias: Cov raj xa dej raug kos los ntawm kev tuag kom ua tiav qhov ntev.

4. Kev Ua Kub: Kev kho cua sov yog siv los ua kom tau cov khoom siv kho tshuab uas xav tau.

5. Ncaj thiab Txiav: Cov raj raug ncaj thiab txiav rau qhov ntev uas xav tau.

6. Kev Tshuaj Xyuas & Kev Ntsuas: Kev kuaj xyuas zoo kom ua raws li EN 1057 cov qauv.

8.Kev Ntsuas & Kev Tshuaj Xyuas

Womic Steel lav tag nrho kev tswj hwm zoo nrog kev kuaj xyuas tag nrho, suav nrog:

●Kev Tshuaj Xyuas Tshuaj/Spectrographic: Kev txheeb xyuas cov khoom siv los ntawm kev siv cov txheej txheem tshuaj lossis spectroscopic.

●Kev Ntsuas Tensile: Kev ntsuam xyuas lub zog tensile thiab cov khoom elongation (EN 10002-1).

●Kev Ntsuas Qhov Nyuaj: Kev ntsuas qhov nyuaj ntawm cov khoom siv los ntawm txoj kev Vickers (EN ISO 6507-1).

●Kev Ntsuas Cov Pa roj carbon: Kev txiav txim siab ntawm feem pua ntawm cov pa roj carbon siv txoj kev siv EN 723.

●Kev Ntsuas Zaj Duab Xis Carbon: Nrhiav thiab ntsuas qhov muaj zaj duab xis carbon (Annex B).

●Kev Ntsuas Kev Khoov: Kev ntsuam xyuas qhov khoov tau hauv qab

●Kev Ntsuas Kev Nthuav Dav: Kev nthuav dav ntawm qhov kawg ntawm lub raj los ntawm 30% nrog ib45°lub mandrel conical los xyuas kom meej tias nws ductility (EN ISO 8493).

●Kev Ntsuas Flanging: Kev txheeb xyuas qhov tsim ntawm flange (qhov tsawg kawg nkaus 30% nce hauv txoj kab uas hla ntawm lub raj) siv lub cuab yeej nrog lub ces kaum radius 1 hli (EN ISO 8494).

●Kev Tsis Muaj Qhov Tsis Zoo ntawm Kev Ntsuas:

●Kev Ntsuas Tam Sim No Eddy (ECT): Kev Tshawb Pom Cov Qhov Tsis Zoo Ntawm Qhov Chaw/Hauv Av (EN 1971 & Annex C.1).

●Kev Ntsuas Hydrostatic: Kev kuaj xyuas qhov tsis kam ntawm lub siab los ntawm kev ntsuas dej (Anne C.2).

●Kev Ntsuas Pneumatic: Nrhiav qhov xau los ntawm kev siv cua/roj siab (Annex C.3).

●Ceeb Toom: Kev sim hom thawj zaug yuav tsum tau siv ECT; lwm txoj kev yog cov chaw tsim khoom xaiv.

9. Kev kuaj:

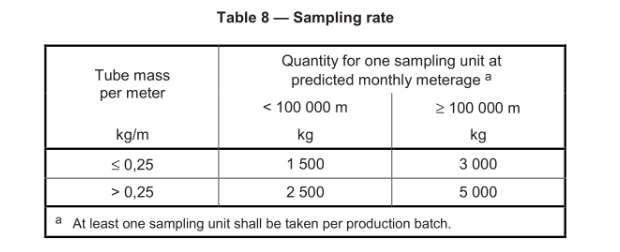

Rau lub hom phiaj ntawm kev paub tseeb zoo thaum lub sijhawm tsim khoom, tus lej ntawm cov chav kuaj uas yuav tsum tau coj mus rau ntawm random yuav tsum yograws li Rooj 8.

Cov nqi kuaj no yuav siv thaum kuaj rau kev tswj qhov ntev; kev tswj hwm ntawm lwm yam khoom yuav tsum tau ua rau txhua chav kuaj thib ob.

Cov txiaj ntsig yuav siv tau los ntawm kev tshuaj xyuas uas tau ua thaum ntxov ntawm kev tsim cov khoom, piv txwv li ntawm theem casting lossis billets sab hauv, yog tias tus kheej ntawm cov khoom raug tswj hwm thiab yog tias lub kaw lus tswj hwm zoo ntawm cov chaw tsim khoom ua raws li cov kev cai ntawm EN lSO 9001.

10.Ntim Khoom

Yuav kom ntseeg tau tias muaj kev nyab xeeb ntawm kev tuav thiab kev thauj mus los, peb cov raj tooj liab tau ntim raws li hauv qab no:

●Txheej Txheej Tiv Thaiv Kev Oxidation: Ib txheej tiv thaiv raug siv rau ntawm qhov chaw ntawm cov raj tooj liab kom tiv thaiv kev oxidation thiab kev hloov xim thaum lub sijhawm khaws cia thiab thauj mus los.

● Lub hau kawg: Cov hau yas lossis cov hlau uas tiv taus xeb tau muab tso rau ntawm cov kawg ntawm lub raj kom tiv thaiv kev ua qias tuaj thiab kev puas tsuaj ntawm lub tshuab.

●Kev Muab Ua Ib Pawg: Cov raj xa dej raug muab faib ua pawg raws li cov lus qhia thiab khi kom ruaj ntseg nrog cov hlua yas muaj zog kom txo qis kev txav mus los thaum thauj mus los.

●Lub Rooj Ntoo: Cov raj uas muab sib txuas ua ke raug muab tso rau hauv cov rooj ntoo uas tiv taus dej noo. Cov rooj ntoo no muaj cov ua npuas dej lossis cov khoom siv desiccant los tiv thaiv kev puas tsuaj los ntawm dej noo thiab ua raws li ISPM 15 cov qauv phytosanitary thoob ntiaj teb.

●Kev Kaw Uas Muaj Zog: Cov thawv raug kaw nrog cov hlau khi lossis cov khoom siv ruaj khov. Kev qhwv me me xaiv tau muaj rau kev tiv thaiv huab cua ntxiv.

● Kev Sau Npe: Txhua lub thawv muaj daim ntawv lo nrog lub raj sab nraud (OD), phab ntsa tuab (WT), ntev, kub (piv txwv li, mos, ib nrab tawv), tus lej ntau lawm, thiab hnub tim kom ntseeg tau tias muaj kev taug qab tag nrho.

11.Kev Thauj Mus Los & Kev Tswj Xyuas Khoom Siv

Womic Steel ua kom muaj kev xa khoom raws sijhawm thiab ruaj ntseg ntawm EN 1057 cov raj tooj liab:

● Kev Thauj Khoom Hauv Hiav Txwv: Kev xa khoom thoob ntiaj teb hauv cov thawv nrog kev ruaj ntseg zoo

●Kev Thauj Mus Los Ntawm Tsheb Ciav Hlau Los Yog Kev Thauj Mus Los Ntawm Txoj Kev: Kev xa khoom hauv tsev thiab hauv cheeb tsam uas ntseeg tau

●Kev Thauj Mus Los Uas Tswj Tau Huab Cua: Muaj rau cov ntawv thov uas rhiab heev

●Cov Ntaub Ntawv Muaj Txhua Yam: Cov ntaub ntawv xa khoom thiab kev pov hwm muab

● Tooj Liab Ntshiab Siab: Kev ruaj khov thiab tiv taus xeb zoo heev

●Kev Tsim Khoom Uas Muaj Kev Ntsuas Zoo: Kev kam rau qhov ntev kom ua tau zoo

●Kev Dais Teeb Meem Tshwj Xeeb: Muaj qhov ntev, kub, thiab txheej txheej uas haum rau koj

●Kev Ntsuas Kom Zoo: Xyuas kom ua raws li cov qauv thoob ntiaj teb

● Kev Faib Tawm Thoob Ntiaj Teb: Kev xa khoom thoob ntiaj teb txhim khu kev qha thiab raws sijhawm

12.Cov txiaj ntsig ntawm kev xaiv Womic Steel

- ● Tooj Liab Ntshiab Siab: Kev ruaj khov thiab tiv taus xeb zoo heev

- ●Kev Tsim Khoom Uas Muaj Kev Ntsuas Zoo: Kev kam rau qhov ntev kom ua tau zoo

- ●Kev Dais Teeb Meem Tshwj Xeeb: Muaj qhov ntev, kub, thiab txheej txheej uas haum rau koj

- ●Kev Ntsuas Kom Zoo: Xyuas kom ua raws li cov qauv thoob ntiaj teb

- ● Kev Faib Tawm Thoob Ntiaj Teb: Kev xa khoom thoob ntiaj teb txhim khu kev qha thiab raws sijhawm

13.Cov ntawv thov

EN 1057 cov kav dej tooj liab siv dav hauv:

- Cov Txheej Txheem Plumbing: Kev faib dej haus kom muaj kev nyab xeeb thiab txhim khu kev qha

- Kev Faib Roj: Zoo tagnrho rau cov roj av thiab LPG daim ntawv thov

- Cov Txheej Txheem Cua Sov: Kev ua haujlwm zoo hauv cov radiators thiab cov cua sov hauv pem teb

- Tub Yees thiab Cua Txias: Kev ua kom muaj cua sov siab rau cov tshuab ua kom txias

- Cov Kav Dej Kho Mob: Ntseeg siab rau cov tsev kho mob rau cov pa oxygen thiab cov pa kho mob

Xaus lus

Womic Steel's EN 1057 Cov Tubes Tooj Liab muab cov khoom zoo tshaj plaws, lub zog, thiab kev ntseeg siab rau cov kav dej, roj, thiab kev siv hauv kev lag luam. Peb txoj kev cog lus rau kev tsim khoom meej, kev sim ua tib zoo, thiab cov kev daws teeb meem rau cov neeg siv khoom ua rau peb yog tus khub koom tes ntseeg siab hauv kev lag luam.

Xaiv Womic Steel Group ua koj tus khub txhim khu kev qha rau qhov zooCov Raj Tooj Liab& Cov khoom siv thiab kev ua tau zoo tshaj plaws. Txais tos nug!

Lub Vas Sab: www.womicsteel.com

Email: sales@womicsteel.com

Xov tooj/WhatsApp/WeChat: Victor: +86-15575100681 los yog Jack: +86-18390957568

Lub sijhawm tshaj tawm: Lub Peb Hlis-10-2025