1. Kev Taw Qhia Txog Cov Kav Dej Hnyav

Cov kav dej tho qhov yog cov khoom tseem ceeb uas txuas cov khoom siv saum npoo av rau cov cuab yeej downhole.Cov Kav Dej Hnyav (HWDP), ua cov kav dej tho qhov tshwj xeeb, ua haujlwm ua lub ntsiab hloov pauv ntawm cov kav dej tho qhov txheem thiab cov caj dab tho qhov. Los ntawm kev tsim qauv zoo tshaj plaws thiab cov ntaub ntawv siab heev, HWDP ua lub luag haujlwm tseem ceeb hauv kev thauj khoom, kev co damping, thiab kev ruaj khov ntawm qhov dej hauv qab cov xwm txheej drilling nyuaj.

Cov yam ntxwv tseem ceeb ntawm kev tsim qauv:

Kev Hloov Pauv ntawm Cov QauvTxuas cov kav dej tho qhov "yooj ywm" thiab cov caj dab tho qhov "ruaj khov", txo qhov kev ntxhov siab ntawm qhov sib tshuam.

Txhim Kho Phab Ntsa Thickness: tuab dua li cov kav dej tho qhov txheem 2–3 npaug thaum tseem tswj tau tib lub cheeb sab nraud (piv txwv li, φ50 mm, φ89 mm) rau kev sib xws ua haujlwm.

Cov Ntawv Thov Ntau Yam: Hloov cov caj dab laum hauv kev khawb qhov me me, txo cov kev pheej hmoo ntawm lub zog torque thiab cov yeeb nkab daig hauv cov qhov dej uas tig mus rau sab, thiab ua rau muaj kev tswj hwm qhov hnyav ntawm cov ntsis (WOB).

2. Kev Tsim Qauv: Kev Paub Tseeb Ob Zaug Txog Lub Zog Thiab Kev Tiv Thaiv Kev Hnav

2.1 Cov Qauv Lub Cev Yeeb Nkab

Tsim Qauv Tu SiabSab hauv, sab nraud, lossis ua ke ntawm cov kav dej kom txhim kho kev tiv taus kev nias thiab kev ua haujlwm qaug zog.

Kev chim siab sab hauv: Tswj qhov dav sab nraud rau cov qhov dej nqaim.

Kev chim siab sab nraud: Ua kom muaj peev xwm thauj khoom axial rau cov qhov dej ntsug.

Kev chim siab ua keZoo tshaj plaws rau cov chaw ib puag ncig hnyav xws li cov qhov dej tob heev.

Kev Xaiv Khoom SivCov hlau nplaum muaj zog heev (piv txwv li, 4145H MOD) nrog lub zog tawm los ntawm 55,000 txog 110,000 KSI.

2.2 Cov cuab yeej siv sib koom ua ke

Cov Cuab Yeej Txuas Ntxiv: Ua kom thaj chaw sib cuag ntau ntxiv kom faib cov khoom hnyav, xws li lub zog nruj, lub zog nias, thiab lub zog torsional.

Cov Kev Sib Txuas:

Kev Sib Txuas Xov: API lossis ob lub xub pwg xov nrog cov sealants rau kev tiv thaiv kev xau.

Cov Qauv Welded: Cov pob qij txha sib txuas ua ke rau cov ntawv thov kev ntxhov siab siab.

2.3 Kev Siv Cov Khoom Siv Uas Tiv Thaiv Tau Kev Hnav Khaub Ncaws

Khoom sivTungsten carbide (HRC ≥60)

Cov HaujlwmTxo cov yeeb nkab lub cev hnav los ntawm 50% hauv cov qhov dej kab rov tav.

Txhim kho kev sib txhuam rau kev ruaj khov ntawm txoj hlua khawb thiab kev tswj hwm txoj kev taug kev.

3. Cov Haujlwm Tseem Ceeb: Txij li Kev Txo Kev Nyuaj Siab mus rau Kev Ruaj Ntseg ntawm Qhov Dej

3.1 Kev Nyuaj Siab Buffering

Kev nqus ntawm kev co: Cov seem uas tig rov qab thiab cov ntaub ntawv elastic hloov cov kev co ntawm lub dab tshos laum mus rau hauv kev tshem tawm lub zog elastic.

Kev co lub zogCov pob qij txha txuas ntxiv rov faib cov kev ntxhov siab torsional, txo qhov kev ua tsis tiav ntawm kev qaug zog hauv cov kav dej txheem.

3.2 Kev Txhim Kho WOB

Qhov Zoo ntawm Qhov HnyavQhov hnyav nruab nrab (piv txwv li, 38 kg/m rau φ89 mm HWDP) ntawm cov kav dej tho thiab cov caj dab.

Kev Tswj Xyuas Kev Hloov KhoKho WOB rau cov shale formations (tiv thaiv cov yeeb nkab daig) thiab cov txheej pob zeb tawv (txhim kho kev nkag mus).

3.3 Txoj Kev Mus Los thiab Kev Ncaj Ncees ntawm Lub Qhov Dej

Kev Ruaj Ntseg ntawm Kev Taw Qhia: Kev siv cov ntaub thaiv tawv txo qhov kev co ntawm cov hlua khawb, tswj cov kev taug kev uas tau npaj tseg.

Tiv Thaiv Kev Sib TsooTxo cov kev ntxhov siab hauv zos los ntawm kev khoov, thaum cov av nkos ncig ua kom lub qhov huv.

4. Cov Kev Siv Tau

4.1 Kev Khawb Qhov Dej tob heev

Kev Kawm Txog Cov Ntaub Ntawv: Tashen-1 Qhov Dej (qhov tob 8,408 m, >200°C, siab 140 MPa).

Kev ua tau zoo: Cov hlau nplaum uas tiv taus kub thiab cov qauv tsim uas tsis zoo tau kov yeej cov qauv abrasive thiab kev ntxhov siab cyclic.

4.2 Cov Xwm Txheej Geological Nyuaj

Cov Chaw Muaj Roj Qab ZibJiaoye-1HF Qhov Dej (Fuling Shale Gas Field) siv cov hlau sib xyaw thiab cov txheej tiv taus xeb los tawm tsam H₂S.

Cov Qhov Dej Qhia/Kab Rov Qab: Hom HWDP uas muaj kauv txo qhov kev sib txhuam thiab txhim kho kev tswj hwm kev taw qhia.

5. Kev Txhim Kho Txog Kev Siv Tshuab

5.1 Kev Tsim Khoom Tshiab

Kev Kho Mob Kub: Quenching thiab tempering los txhim kho qhov cuam tshuam toughness.

Kev Tswj Xyuas Zoo100% kev kuaj ultrasonic (UT) thiab kev tshuaj xyuas cov khoom sib nqus (MPI).

5.2 Kev Tsim Khoom Siv Ntse

Kev Sib Koom Tes MES/ERP: Kev taug qab tag nrho cov txheej txheem los ntawm kev txiav txim mus rau kev xa khoom.

Cov Kev Xaiv Kho Kom Haum: Kev sib txuas ob lub xub pwg, txoj hlua khi ntev, thiab cov txheej yas sab hauv.

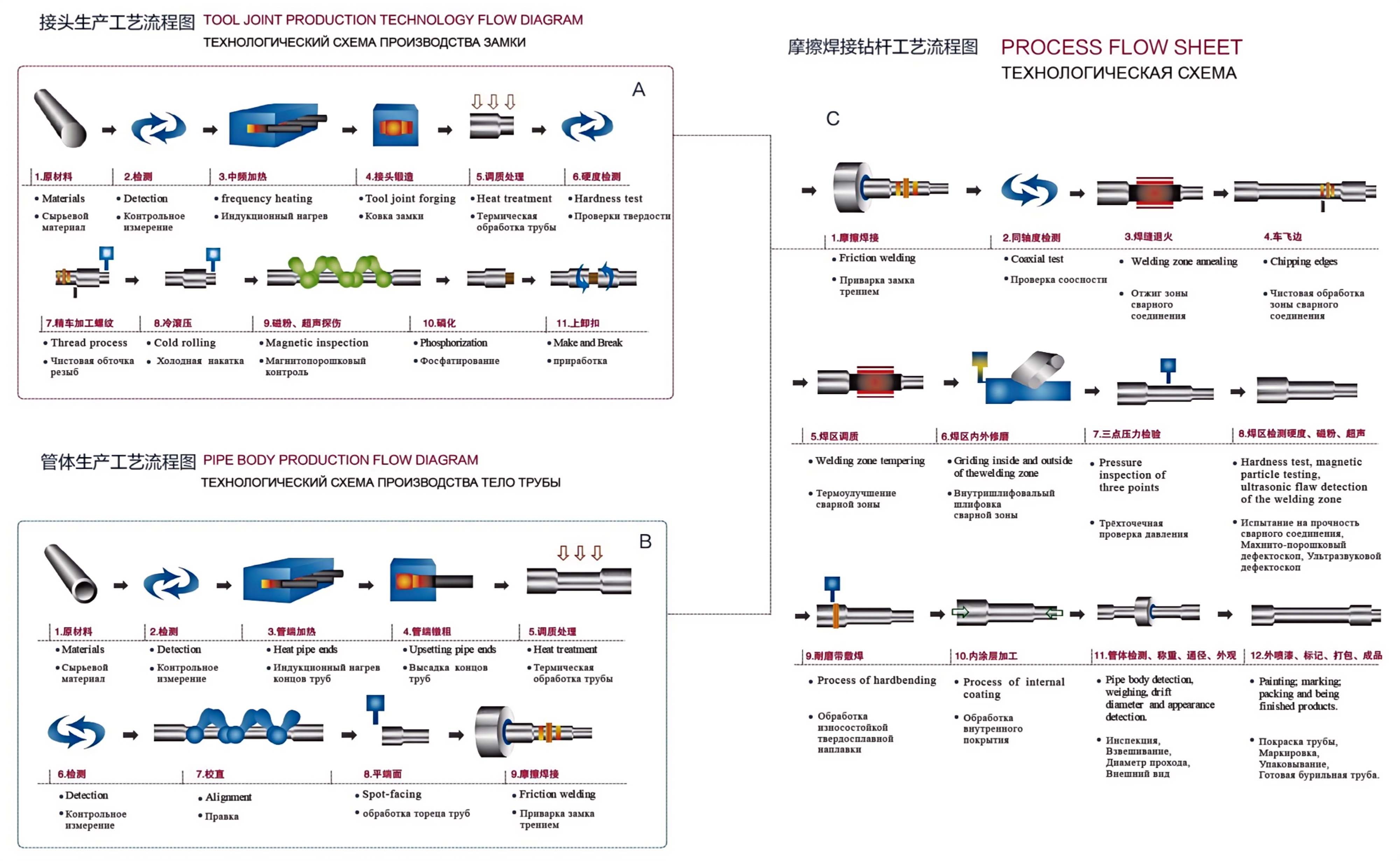

6. Txheej Txheem Tsim Khoom

Kev Xaiv Khoom Siv: 4145H MOD hlau alloy.

Kev Ua Yeeb NkabKev Kho Mob: Drilling → upset forging → kev kho cua sov.

Kev Tsim Khoom Siv Sib Koom TesKev sib tsoo → xov txias dov → phosphating.

Kev Vuam / Kev Sib Dhos: Kev sib txhuam vuam lossis kev ua haujlwm sib xyaw.

Kev Tswj Xyuas ZooKev ntsuas qhov tuab ntawm UT, kev sim qhov nyuaj, kev lees paub qhov siab.

Kev Kho Mob NtoSiv: Siv rau kev tiv thaiv corrosion thiab kev kho kom zoo nkauj ntawm cov khoom siv hlau.

Xaus lus

Ua lub hauv paus tseem ceeb ntawm cov thev naus laus zis niaj hnub no, HWDP sib xyaw ua ke cov qauv tsim kho tshiab thiab kev tshawb fawb txog cov khoom siv los txhim kho kev nyab xeeb thiab kev ua haujlwm ntawm qhov drilling. Txij li cov qhov dej tob heev mus rau cov corrosive formations, nws lub luag haujlwm ob yam ua "kev hloov pauv yooj yim" thiab "kev txhawb nqa ruaj khov" txuas ntxiv thawb cov ciam teb ntawm kev tshawb nrhiav roj thiab roj av.

Xaiv Womic Steel Group ua koj tus khub txhim khu kev qha rau cov kav dej tho thiab kev ua haujlwm xa khoom zoo tshaj plaws. Txais tos nug!

Lub Vas Sab: www.womicsteel.com

Email: sales@womicsteel.com

Xov tooj/WhatsApp/WeChat: Victor: +86-15575100681 los yog Jack: +86-18390957568

Lub sijhawm tshaj tawm: Plaub Hlis-11-2025