1. Tus Qauv: SANS 719

2. Qib: C

3. Hom: Hluav Taws Xob Tiv Thaiv Welded (ERW)

4. Qhov Loj Ntau:

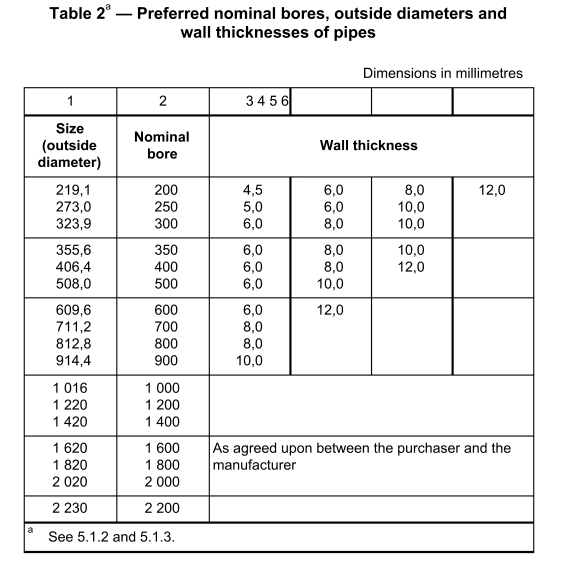

- Sab nraud txoj kab uas hla: 10mm txog 610mm

- Phab ntsa tuab: 1.6mm txog 12.7mm

5. Ntev: 6 meters, lossis raws li xav tau

6. Xaus: Qhov kawg tiaj tus, qhov kawg beveled

7. Kev Kho Mob Nto:

- Dub (tus kheej xim)

- Roj

- Galvanized

- Pleev xim

8. Daim Ntawv Thov: Dej, dej phwj tuaj, kev thauj mus los ntawm cov kua dej dav dav

9. Cov Tshuaj Lom Zem:

- Cov pa roj carbon (C): 0.28% siab tshaj

- Manganese (Mn): 1.25% siab tshaj

- Phosphorus (P): 0.040% siab tshaj

- Sulfur (S): 0.020% siab tshaj

- Silicon (Si): 0.04% siab tshaj. Los yog 0.135% txog 0.25%

10. Cov Khoom Siv Kho Tshuab:

- Lub zog Tensile: 414MPa feeb

- Lub zog tawm los: 290 MPa feeb

- Kev ntev: 9266 faib los ntawm tus nqi lej ntawm UTS tiag tiag

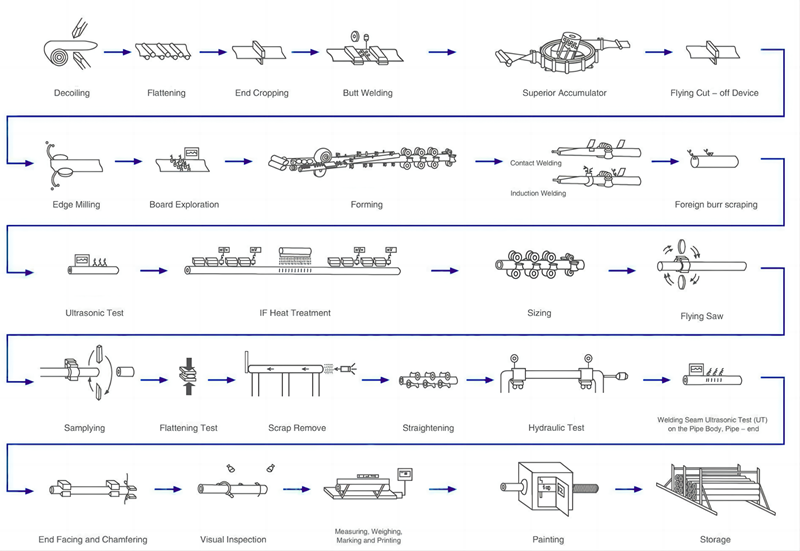

11. Txheej Txheem Tsim Khoom:

- Cov yeeb nkab yog tsim los ntawm kev siv cov txheej txheem txias-tsim thiab high-frequency induction welded (HFIW).

- Cov kab txaij yog tsim los ua ib lub raj thiab welded longitudinally siv high-frequency induction welding.

12. Kev Tshuaj Xyuas thiab Kev Ntsuas:

- Kev tshuaj xyuas tshuaj ntawm cov khoom siv raw

- Kev sim tensile transverse kom paub tseeb tias cov khoom siv kho tshuab ua raws li cov lus qhia

- Kev sim ua kom tiaj tus kom ntseeg tau tias cov yeeb nkab muaj peev xwm tiv taus kev hloov pauv

- Kev sim khoov hauv paus (hluav taws xob fusion welds) kom ntseeg tau tias cov yeeb nkab muaj kev ywj pheej thiab kev ncaj ncees

- Kev sim hydrostatic kom paub tseeb tias cov yeeb nkab xau-nruj

13. Kev Ntsuas Tsis Ua Rau Puas Tsuaj (NDT):

- Kev kuaj xyuas ultrasonic (UT)

- Kev sim tam sim no eddy (ET)

14. Daim Ntawv Pov Thawj:

- Daim ntawv pov thawj kuaj zeb (MTC) raws li EN 10204/3.1

- Kev tshuaj xyuas los ntawm lwm tus (xaiv tau)

15. Ntim:

- Hauv cov pob khoom

- Cov hau yas rau ob sab kawg

- Daim ntawv tiv dej lossis daim ntawv hlau npog

- Cim: raws li qhov xav tau (xws li Chaw Tsim Khoom, qib, qhov loj me, tus qauv, tus lej cua sov, Tus lej ntau thiab lwm yam)

16. Kev xa khoom:

- Raws li dov

- Ua kom zoo li qub

- Normalized dov

17. Kev cim:

- Txhua lub yeeb nkab yuav tsum tau cim kom nyeem tau yooj yim nrog cov ntaub ntawv hauv qab no:

- Lub npe ntawm tus neeg tsim khoom lossis lub cim lag luam

- SANS 719 Qib C

- Loj (sab nraud txoj kab uas hla thiab phab ntsa tuab)

- Tus lej cua sov lossis tus lej batch

- Hnub tsim khoom

- Cov ntaub ntawv pov thawj kuaj xyuas thiab kuaj xyuas

18. Cov Kev Cai Tshwj Xeeb:

- Cov kav dej tuaj yeem muab nrog cov txheej tshwj xeeb lossis cov ntaub thaiv rau cov ntawv thov tshwj xeeb (piv txwv li, txheej epoxy rau kev tiv thaiv corrosion).

19. Kev Ntsuam Xyuas Ntxiv (Yog Tias Yuav Tsum Tau):

- Kev sim cuam tshuam Charpy V-notch

- Kev sim qhov nyuaj

- Kev tshuaj xyuas macrostructure

- Kev tshuaj xyuas microstructure

20. Kev kam rau siab:

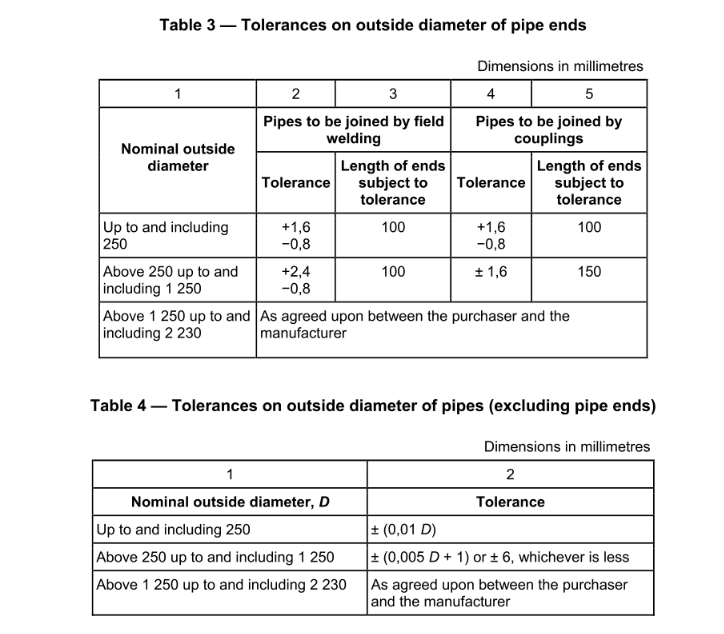

-Sab Nraud Txoj Kab Uas hla

-Ntoo tuab

Lub phab ntsa tuab ntawm cov yeeb nkab yuav tsum, raws li kev kam rau siab ntawm + 10% lossis -8%, yog ib qho ntawm cov nqi cuam tshuam uas tau muab rau hauv kab 3 txog 6 ntawm cov lus hauv qab no, tshwj tsis yog tias tau pom zoo lwm yam ntawm tus neeg tsim khoom thiab tus neeg yuav khoom.

-Kev Ncaj Ncees

Txhua qhov kev hloov pauv ntawm cov yeeb nkab los ntawm txoj kab ncaj, yuav tsum tsis pub tshaj 0,2% ntawm qhov ntev ntawm cov yeeb nkab.

Txhua qhov tsis sib npaug (tsis yog qhov uas tshwm sim los ntawm kev sag), ntawm cov kav dej ntawm sab nraud txoj kab uas hla loj dua 500 hli yuav tsum tsis pub tshaj 1% ntawm sab nraud txoj kab uas hla (piv txwv li qhov siab tshaj plaws ovality 2%) lossis 6 hli, qhov twg tsawg dua.

Thov nco ntsoov tias daim ntawv qhia txog cov ntaub ntawv no muab cov ntaub ntawv qhia txogSANS 719 Qib C kav dejCov kev cai tshwj xeeb yuav txawv raws li qhov project thiab qhov tseeb ntawm cov yeeb nkab xav tau.

Lub sijhawm tshaj tawm: Plaub Hlis-28-2024