SLAG POT yog ib qho tseem ceeb hauv cov txheej txheem ua hlau, siv rau kev tswj thiab tshem tawm cov slag. Womic Steel, lub tuam txhab tsim khoom ntawm SLAG POTS, muab cov khoom zoo nrog kev ua tau zoo. Tsab xov xwm no muab cov lus qhia ntxaws ntxaws ntawm SLAG POT, tsom mus rau nws cov txheej txheem tsim khoom, cov kev cai lij choj, Womic Steel lub peev xwm tsim khoom, qhov zoo, thiab cov ntaub ntawv xa tawm.

Womic Steel sawv tawm ua tus thawj coj tsim khoom ntawm SLAG POTS, qhia txog cov chaw tsim khoom tshiab thiab kev cog lus rau qhov zoo tsis sib xws. Peb cov khoom siv ntau yam suav nrog cranes nrog lub peev xwm nqa tau siab tshaj plaws ntawm 260 tons, nrog rau ntau yam arc furnaces suav nrog 5-tuj, 30-tuj, thiab 80-tuj muaj peev xwm. Tsis tas li ntawd, peb cov kab ntau lawm muaj 20T / h resin xuab zeb kab, 150-tuj rotating rooj tua blasting tshuab, thiab peb CNC kub siab kho cua sov furnaces ntsuas 12m × 7m × 5m, 8m × 4m × 3.5m, thiab 8m × 4m × 3.3m feem. Peb khav txog 30,000-square-meter hluav taws xob cua sov plua plav tshem tawm system thiab ntau yam khoom siv machining xws li 8m, 6.3m, thiab 5m ntsug lathes, nrog rau 220 tho txawv thiab milling tshuab.

Peb lub chaw kuaj mob tshwj xeeb muaj lub chaw kuaj tshuaj lom neeg, lub tshuab ntsuas qhov ntsuas ncaj qha, lub tshuab kuaj tensile 60-tuj, lub tshuab kuaj kev cuam tshuam, lub tshuab ntsuas qhov tsis zoo ultrasonic, lub tshuab ntsuas Rockwell hardness, thiab lub tshuab microscope metallurgical, kom ntseeg tau tias muaj kev tswj hwm zoo ntawm txhua theem ntawm kev tsim khoom.

Nrog ntau tshaj 20 xyoo ntawm kev paub hauv kev lag luam casting, Womic Steel muaj lub chaw tsim khoom siv thev naus laus zis thoob ntiaj teb thiab pab pawg kws tshaj lij. Tshwj xeeb hauv kev tsim cov khoom loj thiab loj heev cam khwb cia hlau, peb cov txheej txheem tsim khoom siv kev siv co-casting, nrog rau ib qho kev tsim khoom co-casting ntawm kwv yees li 400 tons, thiab cov castings ib leeg hnyav txog li 300 tons. Peb cov khoom pom daim ntawv thov hauv ntau yam lag luam, suav nrog kev khawb av cement, kev tsim nkoj, forging, metallurgy, engineering machinery, kev tsim kho txoj kev thiab choj, kev txuag dej, thiab lub zog nuclear, muab cov khoom siv carbon thiab alloy steel zoo hauv ntau yam ntau yam thiab cov lus qhia rau cov khoom siv tseem ceeb.

Kev tsim kho tshiab, zoo tshaj plaws, thiab kev pabcuam zoo tshaj plaws yog lub hauv paus ntawm peb lub tswv yim ua lag luam. Los ntawm kev nce qib thev naus laus zis tas mus li, peb tau tsim cov khoom siv hlau siv dav dav xws li SLAG POTS thiab cov pwm hlau ingot, uas raug xa tawm thoob ntiaj teb. Peb cov SLAG POTS muaj txij li 3 cubic meters txog 45 cubic meters, nrog rau cov pwm hlau ingot hnyav txij li 3.5 tons txog 175 tons, txhua yam ua tau raws li cov qauv kev lag luam ua ntej. Peb tau tsim kev koom tes ntev nrog ntau lub koom haum hlau nto moo thoob ntiaj teb, suav nrog SMS Group hauv lub teb chaws Yelemees, POSCO hauv Kaus Lim Qab Teb, thiab JFE hauv Nyiv Pooj, tau txais kev qhuas los ntawm cov neeg siv khoom thoob ntiaj teb.

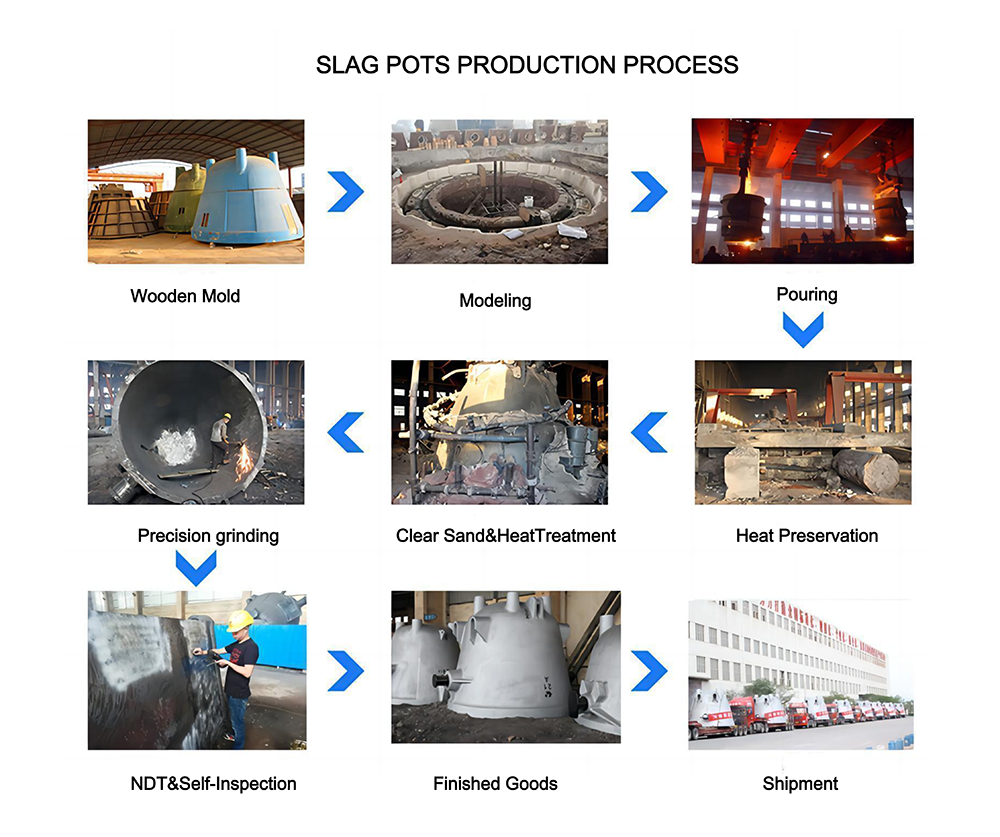

Hauv kev tsim cov SLAG POTS, Womic Steel hais txog kev tsim kho tshiab, siv cov txheej txheem hlau cam khwb cia siab heev thiab cov software systems kom ua tiav lub voj voog tsim khoom kwv yees li 40 hnub rau ib lub lauj kaub. Nrog rau qhov nruab nrab siv zaus ntawm 6000 zaug, peb cov SLAG POTS ntau dua li cov qauv kev ua lag luam hauv kev ruaj khov thiab lub neej ntev. Tsis tas li ntawd, peb cov lauj kaub raug cam khwb cia ua ib daim, ua kom lawv tsis yooj yim deformation. Nrog koj cov duab kos hauv tes, Womic Steel tuaj yeem xa cov castings zoo uas koj xav tau.

Ua ntej casting, peb simulate cov txheej txheem casting siv CAE software los tshuaj xyuas thiab kwv yees cov txheej txheem molding thiab qhov zoo ntawm cov khoom, txuas ntxiv mus optimize cov txheej txheem ntawm SLAG POT casting. Peb cov cuab yeej metallurgical ua kom ntseeg tau tias zoo tag nrho kev tswj qhov loj me, siv sodium silicate xuab zeb molding technology los tiv thaiv qhov tshwm sim ntawm cov kab nrib pleb kub hauv castings. Peb siv qhov pit molding, uas tsis cuam tshuam los ntawm lub caij, kom ntseeg tau tias muaj kev ua haujlwm siab.

Thaum lub sijhawm nchuav thiab kho cua sov, peb yaj cov khoom siv raw uas tau kuaj xyuas hauv lub cub tawg arc, tshuaj xyuas cov hlau uas yaj los ntawm spectroscopy tom qab kuaj, thiab nchuav nws raws li lub hauv paus ntsiab lus ntawm "kev nchuav sai sai thaum kub qis," sau lub sijhawm nchuav thiab kub. Txhawm rau daws qhov sib txawv tseem ceeb ntawm cov pa roj carbon ntawm cov hlau alloy axle thiab cov hlau carbon ntawm lub cev tank, peb tau tsim cov txheej txheem tiav los tswj cov teeb meem vuam thaum lub sijhawm tsim khoom.

Tom qab casting, peb ua haujlwm xws li txiav risers thiab burrs. Womic Steel muaj pab pawg neeg sib tsoo thiab ua tiav thiab cov khoom siv tua phom loj los txhim kho qhov zoo ntawm SLAG POTS, ua tiav qhov tiav ntawm qhov chaw uas cov neeg siv khoom xav tau. Peb kuj siv cov khoom siv sim tsis puas tsuaj siab heev los ua qhov kev sim tsis puas tsuaj ntawm txhua SLAG POT kom ntseeg tau tias nws zoo sab hauv, tiv thaiv cov khoom puas tsuaj los ntawm kev tawm hauv lub Hoobkas.

SLAG POTS yog cov khoom siv tseem ceeb hauv cov txheej txheem ua hlau ntawm cov tuam txhab ua hlau. Ntawm Womic Steel, peb muab kev tsim kho tshiab nrog kev siv tshuab casting thiab software systems, txo qhov kev voj voog casting ntawm SLAG POTS mus rau kwv yees li 30 hnub. Peb cov SLAG POTS muaj kev tiv thaiv deformation zoo, ua rau lawv lub neej ntev dua piv rau cov qauv kev ua lag luam. Nrog koj cov duab kos, peb tuaj yeem tsim cov castings zoo uas koj xav tau.

Vim li cas thiaj xaiv Womic Steel?

1. Cov xaj los ntawm International Giants: Peb tau txais cov xaj txhua xyoo tshaj 100 SLAG POTS los ntawm cov tuam txhab hlau nto moo xws li Mittal Group, ua rau peb yog lawv tus khub koom tes ntev.

2. Kev Pab Cuam Ntev Dua: Peb cov SLAG POTS muaj lub neej ua haujlwm ntev dua 20% piv rau cov qauv kev ua lag luam, nrog rau kev txij nkawm thawj zaug ncua sijhawm 2-3 lub hlis piv rau cov neeg sib tw.

3. Qib 2 Kev Tshuaj Xyuas Tus Qauv: Peb siv cov khoom siv kuaj tsis ua puas tsuaj kom ntseeg tau tias txhua lub SLAG POT ua tau raws li qib 2 kev tshuaj xyuas hauv tebchaws lossis cov qauv tshuaj xyuas tshwj xeeb uas cov neeg siv khoom thov.

4. Kev Kho Kom Haum Rau Cov Neeg Siv Khoom Thoob Ntiaj Teb: Peb cov khoom lag luam SLAG POT tseem ceeb, uas paub txog nws qhov kev ua haujlwm siab, tuaj yeem kho kom haum rau cov kev xav tau tshwj xeeb ntawm cov neeg siv khoom thoob ntiaj teb. Peb cov khoom tau raug xa tawm mus rau ntau dua 60 lub tebchaws thiab thaj chaw, suav nrog Tebchaws Meskas, Mexico, Brazil, Is Nrias teb, Kaus Lim Qab Teb, Nyiv Pooj, thiab Lavxias.

Womic Steel ua raws li cov qauv tsim khoom nruj, suav nrog GB / T 20878-200, ASTM A27 / A27M, ASTM A297 / A297M-20, ISO 4990: 2015, BS EN 1561: 2011, JIS G 5501: 2018, DIN EN 1559, DIN 1681: 2007-08, thiab lwm yam ... Xyuas kom meej tias qhov zoo tshaj plaws thiab kev ua tau zoo ntawm SLAG POTS.

Nrog lub peev xwm tsim khoom ntawm 55,000 tons hauv ib xyoos thiab ua raws li ISO 9001: 2015 lub teb chaws zoo tswj kev lees paub, Womic Steel lav qhov zoo ntawm peb cov SLAG POTS thiab xyuas kom meej tias xa khoom raws sijhawm. Peb tau txais kev qhuas los ntawm ntau tus neeg siv khoom koom tes rau peb qhov kev xa khoom raws sijhawm.

Peb pab neeg uas muaj kev paub dhau los muab cov kev daws teeb meem kev tshaj lij uas tsim los rau koj cov kev xav tau tshwj xeeb, kom ntseeg tau tias muaj kev tsim khoom zoo ntawm SLAG POTS. Peb ib txwm cob qhia peb cov neeg ua haujlwm pem hauv ntej kom tswj tau qhov zoo ntawm kev tsim khoom ruaj khov.

Koom nrog cov neeg siv khoom txaus siab uas tau ntsib qhov zoo thiab kev pabcuam zoo tshaj plaws ntawm Womic Steel. Tiv tauj peb hnub no rau txhua yam koj xav tau SLAG POT.

Lub sijhawm tshaj tawm: Lub Peb Hlis-21-2024