Kev kho cua sov yog hais txog cov txheej txheem cua sov hlau uas cov khoom siv raug cua sov, tuav thiab txias los ntawm kev cua sov hauv lub xeev khov kho kom tau txais lub koom haum thiab cov khoom xav tau.

I. Kev Kho Mob Kub

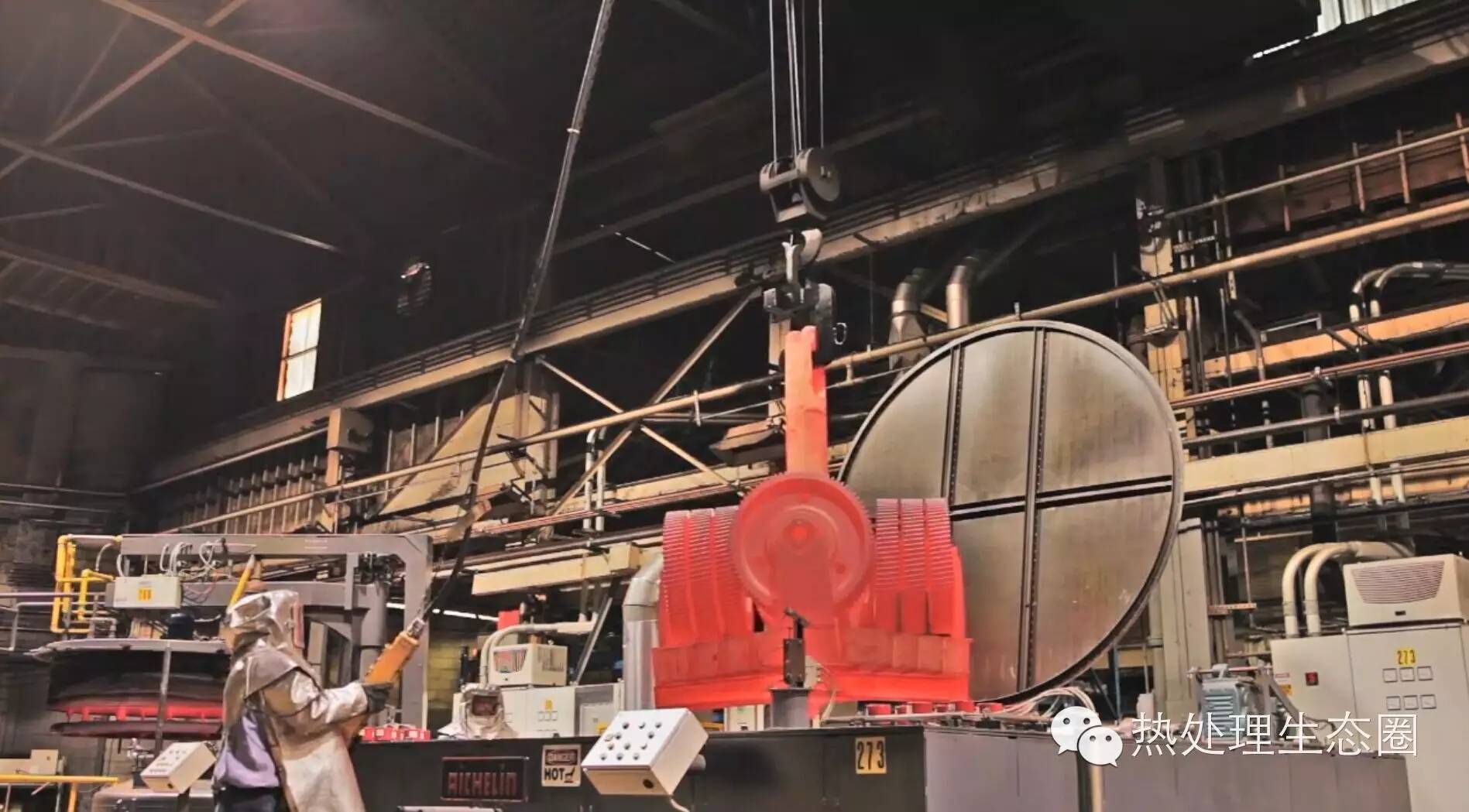

1, Normalizing: cov hlau lossis cov hlau uas raug cua sov mus rau qhov tseem ceeb ntawm AC3 lossis ACM saum qhov kub tsim nyog kom tswj tau ib lub sijhawm tom qab txias hauv huab cua, kom tau txais hom pearlitic ntawm cov txheej txheem kho cua sov.

2, Annealing: eutectic steel workpiece raug cua sov rau AC3 saum 20-40 degrees, tom qab tuav rau ib lub sijhawm, nrog rau lub cub tawg maj mam txias (lossis faus rau hauv xuab zeb lossis txiv qaub txias) rau 500 degrees qis dua qhov txias hauv cov txheej txheem kho cua sov.

3, Kev kho cua sov ntawm cov khoom khov kho: cov hlau alloy raug cua sov rau thaj chaw kub siab ib theem ntawm qhov kub tas li kom tswj tau, yog li ntawd cov theem ntau dhau tau yaj tag nrho rau hauv cov khoom khov kho, thiab tom qab ntawd txias sai sai kom tau txais cov txheej txheem kho cua sov ntawm cov khoom khov kho supersaturated.

4, Kev Laus: Tom qab kho cov khoom khov kho lossis cov yas deformation txias ntawm cov hlau, thaum nws muab tso rau hauv chav tsev kub lossis khaws cia ntawm qhov kub me ntsis siab dua li chav tsev kub, qhov tshwm sim ntawm nws cov khoom hloov pauv nrog lub sijhawm.

5, Kev kho cov khoom khov kho: yog li ntawd cov hlau hauv ntau theem yaj tag, ua kom cov khoom khov kho muaj zog thiab txhim kho qhov tawv thiab tiv taus corrosion, tshem tawm kev ntxhov siab thiab mos, txhawm rau txuas ntxiv ua cov txheej txheem molding.

6, Kev kho mob laus: cua sov thiab tuav ntawm qhov kub ntawm cov nag lossis daus ntawm theem txhawb nqa, yog li ntawd cov nag lossis daus ntawm theem txhawb nqa kom nag lossis daus, kom tawv, kom txhim kho lub zog.

7, Quenching: hlau austenitization tom qab txias ntawm qhov txias tsim nyog, yog li ntawd cov khoom ua haujlwm hauv qhov seem ntawm tag nrho lossis qee qhov ntau ntawm cov qauv tsis ruaj khov xws li martensite hloov pauv ntawm cov txheej txheem kho cua sov.

8, Tempering: qhov workpiece quenched yuav raug cua sov mus rau qhov tseem ceeb ntawm AC1 hauv qab qhov kub tsim nyog rau ib lub sijhawm, thiab tom qab ntawd txias raws li qhov yuav tsum tau ua ntawm txoj kev, txhawm rau kom tau txais lub koom haum xav tau thiab cov khoom ntawm cov txheej txheem kho cua sov.

9, Carbonitriding Hlau: Carbonitriding yog rau txheej hlau ntawm tib lub sijhawm infiltration ntawm carbon thiab nitrogen. Carbonitriding ib txwm muaj kuj hu ua cyanide, nruab nrab kub roj carbonitriding thiab qis kub roj carbonitriding (piv txwv li roj nitrocarburizing) yog siv dav dua. Lub hom phiaj tseem ceeb ntawm nruab nrab kub roj carbonitriding yog los txhim kho qhov nyuaj, hnav tsis kam thiab qaug zog ntawm hlau. Carbonitriding qis-kub roj carbonitriding rau nitriding-raws li, nws lub hom phiaj tseem ceeb yog los txhim kho cov hlau hnav tsis kam thiab tom tsis kam.

10, Kev kho mob tempering (quenching thiab tempering): cov kev cai dav dav yuav raug quenched thiab tempered ntawm qhov kub siab ua ke nrog kev kho cua sov hu ua kev kho mob tempering. Kev kho mob tempering yog siv dav hauv ntau yam khoom tseem ceeb, tshwj xeeb tshaj yog cov neeg ua haujlwm hauv qab kev sib hloov ntawm cov pas nrig txuas, bolts, iav thiab shafts. Tempering tom qab kev kho mob tempering kom tau txais lub koom haum tempered sohnite, nws cov khoom siv kho tshuab zoo dua li tib qhov nyuaj ntawm lub koom haum normalized sohnite. Nws qhov nyuaj nyob ntawm qhov kub siab tempering kub thiab hlau tempering ruaj khov thiab qhov loj ntawm qhov chaw ua haujlwm, feem ntau ntawm HB200-350.

11, Brazing: nrog cov khoom siv brazing yuav muaj ob hom workpiece cua sov melting sib txuas ua ke cua sov kho txheej txheem.

II.Tcov yam ntxwv ntawm cov txheej txheem

Kev kho cua sov hlau yog ib qho ntawm cov txheej txheem tseem ceeb hauv kev tsim khoom siv tshuab, piv rau lwm cov txheej txheem machining, kev kho cua sov feem ntau tsis hloov pauv cov duab ntawm cov khoom ua haujlwm thiab cov tshuaj lom neeg tag nrho, tab sis los ntawm kev hloov pauv sab hauv microstructure ntawm cov khoom ua haujlwm, lossis hloov pauv cov tshuaj lom neeg ntawm qhov chaw ntawm cov khoom ua haujlwm, los muab lossis txhim kho kev siv cov khoom ua haujlwm. Nws yog tus cwj pwm los ntawm kev txhim kho hauv qhov zoo ntawm cov khoom ua haujlwm, uas feem ntau tsis pom rau lub qhov muag liab qab. Yuav kom ua rau cov khoom ua haujlwm hlau nrog cov khoom siv kho tshuab, cov khoom siv lub cev thiab cov tshuaj lom neeg xav tau, ntxiv rau kev xaiv cov ntaub ntawv tsim nyog thiab ntau yam txheej txheem molding, cov txheej txheem kho cua sov feem ntau yog qhov tseem ceeb. Hlau yog cov ntaub ntawv siv dav tshaj plaws hauv kev lag luam kho tshuab, cov khoom siv hlau microstructure, tuaj yeem tswj tau los ntawm kev kho cua sov, yog li kev kho cua sov ntawm hlau yog cov ntsiab lus tseem ceeb ntawm kev kho cua sov hlau. Tsis tas li ntawd, txhuas, tooj liab, magnesium, titanium thiab lwm yam alloys kuj tuaj yeem kho cua sov kom hloov pauv nws cov khoom siv kho tshuab, lub cev thiab tshuaj lom neeg, kom tau txais kev ua tau zoo sib txawv.

III.Tnws cov txheej txheem

Feem ntau cov txheej txheem kho cua sov muaj peb txoj kev ua kom sov, tuav, thiab txias, qee zaum tsuas yog ua kom sov thiab txias ob txoj kev ua. Cov txheej txheem no txuas nrog ib leeg, tsis tuaj yeem cuam tshuam.

Kev cua sov yog ib qho ntawm cov txheej txheem tseem ceeb ntawm kev kho cua sov. Kev kho cua sov ntawm ntau txoj kev cua sov, qhov ntxov tshaj plaws yog kev siv thee thiab thee ua qhov chaw cua sov, tsis ntev los no kev siv roj thiab roj av. Kev siv hluav taws xob ua rau kev cua sov yooj yim tswj, thiab tsis muaj kuab paug rau ib puag ncig. Kev siv cov cua sov no tuaj yeem ua kom sov ncaj qha, tab sis kuj los ntawm cov ntsev molten lossis hlau, rau cov khoom ntab rau kev cua sov tsis ncaj qha.

Thaum cov hlau ua kom sov, cov khoom ua haujlwm raug cua, oxidation, thiab decarburization feem ntau tshwm sim (piv txwv li, cov pa roj carbon ntawm cov hlau yuav txo qis), uas muaj kev cuam tshuam tsis zoo rau cov khoom ntawm cov khoom ua kom sov. Yog li ntawd, cov hlau feem ntau yuav tsum nyob hauv huab cua tswj lossis huab cua tiv thaiv, ntsev yaj thiab cua sov nqus tsev, tab sis kuj muaj cov txheej txheem tiv thaiv lossis cov txheej txheem ntim khoom rau kev tiv thaiv cua sov.

Qhov kub ntawm cua sov yog ib qho tseem ceeb ntawm cov txheej txheem kho cua sov, kev xaiv thiab tswj qhov kub ntawm cua sov, yog los xyuas kom meej tias qhov zoo ntawm kev kho cua sov ntawm cov teeb meem tseem ceeb. Qhov kub ntawm cua sov txawv nrog cov khoom siv hlau kho thiab lub hom phiaj ntawm kev kho cua sov, tab sis feem ntau yog cua sov siab dua qhov kub hloov pauv theem kom tau txais kev teeb tsa kub siab. Tsis tas li ntawd, kev hloov pauv yuav tsum tau siv sijhawm ntev, yog li thaum lub ntsej muag ntawm cov hlau ua haujlwm kom ua tiav qhov kub ntawm cua sov xav tau, tab sis kuj yuav tsum tau tswj hwm ntawm qhov kub no rau ib lub sijhawm, kom qhov kub sab hauv thiab sab nraud sib xws, kom qhov kev hloov pauv microstructure tiav, uas hu ua lub sijhawm tuav. Kev siv cua sov siab thiab kev kho cua sov ntawm qhov chaw, qhov kub ntawm cua sov yog ceev heev, feem ntau tsis muaj sijhawm tuav, thaum lub sijhawm kho cua sov tshuaj feem ntau ntev dua.

Kev txias kuj yog ib kauj ruam tseem ceeb hauv cov txheej txheem kho cua sov, cov txheej txheem txias vim muaj ntau yam txheej txheem, feem ntau yog los tswj qhov txias. Feem ntau, qhov txias qeeb tshaj plaws thaum annealing, qhov txias sai dua thaum normalizing, qhov txias sai dua thaum quenching. Tab sis kuj vim muaj ntau hom hlau sib txawv thiab muaj cov kev cai sib txawv, xws li cov hlau uas tau ua kom tawv los ntawm huab cua tuaj yeem quenched nrog qhov txias tib yam li normalizing.

IV.Pkev faib tawm ntawm txoj haujlwm

Cov txheej txheem kho cua sov ntawm cov hlau muaj peb pawg: kev kho cua sov, kev kho cua sov saum npoo av thiab kev kho cua sov tshuaj lom neeg. Raws li cov khoom siv cua sov, qhov kub thiab txias ntawm cov khoom sib txawv, txhua pawg muaj ntau hom kev kho cua sov sib txawv. Cov hlau zoo ib yam siv cov txheej txheem kho cua sov sib txawv, tuaj yeem tau txais cov khoom sib txawv, yog li muaj cov yam ntxwv sib txawv. Hlau thiab hlau yog cov hlau siv dav tshaj plaws hauv kev lag luam, thiab cov qauv hlau kuj yog qhov nyuaj tshaj plaws, yog li muaj ntau hom txheej txheem kho cua sov hlau.

Kev kho cua sov tag nrho yog kev ua kom sov tag nrho cov khoom ua haujlwm, thiab tom qab ntawd txias ntawm qhov nrawm tsim nyog, kom tau txais lub koom haum metallurgical xav tau, txhawm rau hloov nws cov khoom siv kho tshuab tag nrho ntawm cov txheej txheem kho cua sov hlau. Kev kho cua sov tag nrho ntawm cov hlau kwv yees li annealing, normalizing, quenching thiab tempering plaub txoj hauv kev yooj yim.

Txheej txheem txhais tau tias:

Annealing yog lub workpiece raug cua sov rau qhov kub thiab txias, raws li cov khoom siv thiab qhov loj ntawm lub workpiece siv lub sijhawm tuav sib txawv, thiab tom qab ntawd maj mam txias, lub hom phiaj yog ua kom lub koom haum sab hauv ntawm cov hlau ua tiav lossis ze rau lub xeev sib npaug, kom tau txais kev ua tau zoo thiab kev ua tau zoo, lossis rau kev quenching ntxiv rau lub koom haum ntawm kev npaj.

Kev ua kom zoo yog tias cov khoom ua haujlwm raug cua sov rau qhov kub thiab txias tom qab txias hauv huab cua, qhov cuam tshuam ntawm kev ua kom zoo zoo ib yam li kev ua kom sov, tsuas yog kom tau txais lub koom haum zoo dua, feem ntau siv los txhim kho kev ua tau zoo ntawm cov khoom siv, tab sis kuj qee zaum siv rau qee qhov tsis tshua xav tau ua kev kho cua sov kawg.

Kev ua kom kub yog qhov ua haujlwm tau raug cua sov thiab rwb thaiv tsev, hauv dej, roj lossis lwm yam ntsev inorganic, cov kua dej organic thiab lwm yam khoom siv quenching kom txias sai. Tom qab quenching, cov khoom hlau ua tawv, tab sis tib lub sijhawm ua brittle, txhawm rau tshem tawm qhov brittleness raws sijhawm, feem ntau nws yog qhov tsim nyog los ua kom sov raws sijhawm.

Yuav kom txo qhov brittleness ntawm cov hlau qhov chaw, cov hlau qhov chaw quenched ntawm qhov kub tsim nyog siab dua chav tsev kub thiab qis dua 650 ℃ rau lub sijhawm ntev ntawm kev rwb thaiv tsev, thiab tom qab ntawd txias, cov txheej txheem no hu ua tempering. Annealing, normalizing, quenching, tempering yog tag nrho cov kev kho cua sov hauv "plaub hluav taws", uas quenching thiab tempering muaj feem cuam tshuam ze, feem ntau siv ua ke nrog ib leeg, ib qho yog qhov tseem ceeb. "Plaub hluav taws" nrog rau qhov kub thiab txias hom sib txawv, thiab tau hloov pauv cov txheej txheem kho cua sov sib txawv. Yuav kom tau txais qee qib ntawm lub zog thiab toughness, quenching thiab tempering ntawm qhov kub siab ua ke nrog cov txheej txheem, hu ua tempering. Tom qab qee cov alloys raug quenched los ua cov kua supersaturated, lawv raug tuav ntawm chav tsev kub lossis ntawm qhov kub tsim nyog me ntsis rau lub sijhawm ntev dua kom txhim kho qhov nyuaj, lub zog, lossis hluav taws xob magnetism ntawm cov hlau. Cov txheej txheem kho cua sov zoo li no hu ua kev laus kho.

Kev ua haujlwm siab deformation thiab kev kho cua sov ua ke zoo thiab ze ua ke, kom cov workpiece tau txais lub zog zoo heev, tawv nrog txoj kev hu ua deformation heat treatment; nyob rau hauv huab cua tsis zoo lossis lub tshuab nqus tsev, kev kho cua sov hu ua lub tshuab nqus tsev, uas tsis tsuas yog ua rau cov workpiece tsis oxidize, tsis decarburize, khaws qhov chaw ntawm workpiece tom qab kho, txhim kho kev ua tau zoo ntawm workpiece, tab sis kuj los ntawm tus neeg sawv cev osmotic rau kev kho cua sov tshuaj.

Kev kho cua sov ntawm qhov chaw tsuas yog cua sov rau txheej txheej ntawm qhov chaw ua haujlwm kom hloov cov khoom siv kho tshuab ntawm txheej txheej ntawm cov txheej txheem kho cua sov hlau. Yuav kom tsuas yog cua sov rau txheej txheej ntawm qhov chaw ua haujlwm yam tsis muaj cua sov ntau dhau mus rau hauv qhov chaw ua haujlwm, kev siv qhov chaw cua sov yuav tsum muaj lub zog ceev ceev, uas yog, nyob rau hauv thaj chaw ntawm qhov chaw ua haujlwm kom muab lub zog cua sov loj dua, yog li ntawd txheej txheej ntawm qhov chaw ua haujlwm lossis thaj chaw tuaj yeem yog lub sijhawm luv luv lossis tam sim ntawd kom ncav cuag qhov kub siab. Kev kho cua sov ntawm qhov chaw ntawm cov txheej txheem tseem ceeb ntawm kev tua hluav taws thiab kev kho cua sov induction, feem ntau siv cov chaw cua sov xws li oxyacetylene lossis oxypropane nplaim taws, induction tam sim no, laser thiab electron beam.

Kev kho cua sov tshuaj yog ib txoj kev kho cua sov hlau los ntawm kev hloov cov tshuaj lom neeg, kev teeb tsa thiab cov yam ntxwv ntawm cov txheej saum npoo ntawm cov khoom ua haujlwm. Kev kho cua sov tshuaj txawv ntawm kev kho cua sov nto vim tias qhov qub hloov cov tshuaj lom neeg ntawm cov txheej saum npoo ntawm cov khoom ua haujlwm. Kev kho cua sov tshuaj yog muab tso rau ntawm cov khoom ua haujlwm uas muaj cov pa roj carbon, ntsev lossis lwm yam khoom sib xyaw ntawm cov khoom nruab nrab (roj, kua, khoom khov) hauv cua sov, rwb thaiv tsev rau lub sijhawm ntev dua, yog li cov pa roj carbon, nitrogen, boron thiab chromium thiab lwm yam khoom nkag mus rau hauv txheej saum npoo ntawm cov khoom ua haujlwm. Tom qab nkag mus rau hauv cov khoom, thiab qee zaum lwm cov txheej txheem kho cua sov xws li quenching thiab tempering. Cov txheej txheem tseem ceeb ntawm kev kho cua sov tshuaj yog carburizing, nitriding, hlau nkag mus.

Kev kho cua sov yog ib qho ntawm cov txheej txheem tseem ceeb hauv cov txheej txheem tsim khoom ntawm cov khoom siv kho tshuab thiab pwm. Feem ntau hais lus, nws tuaj yeem ua kom ntseeg tau thiab txhim kho ntau yam khoom ntawm cov khoom ua haujlwm, xws li kev hnav tsis kam, kev tiv thaiv corrosion. Kuj tseem tuaj yeem txhim kho kev teeb tsa ntawm qhov chaw khoob thiab lub xeev kev ntxhov siab, txhawm rau pab txhawb ntau yam kev ua haujlwm txias thiab kub.

Piv txwv li: hlau dawb cam khwb cia tom qab lub sijhawm ntev annealing kev kho mob tuaj yeem tau txais malleable cam khwb cia hlau, txhim kho plasticity; iav nrog cov txheej txheem kho cua sov kom raug, kev pabcuam lub neej tuaj yeem ntau dua li tsis yog cua sov-kho iav zaug lossis ntau zaus; ntxiv rau, pheej yig carbon hlau los ntawm kev nkag mus ntawm qee cov ntsiab lus alloying muaj qee qhov kev ua tau zoo kim alloy hlau, tuaj yeem hloov qee cov hlau tiv taus cua sov, stainless hlau; pwm thiab tuag yog yuav luag txhua tus yuav tsum tau mus dhau kev kho cua sov Yuav siv tau tsuas yog tom qab kev kho cua sov.

Cov txhais tau ntxiv

I. Hom kev ua kom sov

Kev ua kom kub yog ib txoj kev kho cua sov uas cov khoom ua haujlwm raug cua sov rau qhov kub thiab txias, tuav rau ib lub sijhawm, thiab tom qab ntawd maj mam txias.

Muaj ntau hom txheej txheem annealing hlau, raws li qhov kub thiab txias tuaj yeem muab faib ua ob pawg: ib qho yog nyob rau ntawm qhov kub tseem ceeb (Ac1 lossis Ac3) saum toj no annealing, tseem hu ua theem hloov recrystallization annealing, suav nrog kev ua tiav annealing, tsis tiav annealing, spheroidal annealing thiab diffusion annealing (homogenization annealing), thiab lwm yam; qhov tod tes yog qis dua qhov kub tseem ceeb ntawm annealing, suav nrog recrystallization annealing thiab de-stressing annealing, thiab lwm yam. Raws li txoj kev txias, annealing tuaj yeem muab faib ua isothermal annealing thiab continuous cooling annealing.

1, ua tiav annealing thiab isothermal annealing

Kev ua kom tiav annealing, tseem hu ua recrystallization annealing, feem ntau hu ua annealing, nws yog cov hlau lossis hlau uas tau cua sov rau Ac3 saum 20 ~ 30 ℃, rwb thaiv tsev ntev txaus kom ua rau lub koom haum austenitized tag nrho tom qab txias qeeb, txhawm rau kom tau txais kev sib npaug ntawm cov txheej txheem kho cua sov. Qhov kev ua kom tiav no feem ntau yog siv rau cov khoom sib xyaw sub-eutectic ntawm ntau yam carbon thiab alloy steel castings, forgings thiab kub-rolled profiles, thiab qee zaum kuj siv rau cov qauv welded. Feem ntau feem ntau ua ntau yam khoom siv tsis hnyav kho cua sov kawg, lossis ua kev kho cua sov ua ntej rau qee yam khoom siv.

2, pob annealing

Kev siv spheroidal annealing feem ntau yog siv rau cov hlau carbon uas muaj eutectic ntau dhau thiab cov hlau siv ua hlau sib xyaw (xws li kev tsim cov cuab yeej siv edged, gauges, pwm thiab tuag siv rau hauv cov hlau). Nws lub hom phiaj tseem ceeb yog txo qhov nyuaj, txhim kho kev siv tshuab, thiab npaj rau kev quenching yav tom ntej.

3, kev ntxhov siab annealing

Kev txo kev ntxhov siab annealing, tseem hu ua qis-kub annealing (lossis kub-tempering), qhov annealing no feem ntau yog siv los tshem tawm cov castings, forgings, weldments, kub-dov qhov chaw, txias-kos qhov chaw thiab lwm yam kev ntxhov siab seem. Yog tias cov kev ntxhov siab no tsis raug tshem tawm, yuav ua rau hlau tom qab ib lub sijhawm, lossis hauv cov txheej txheem txiav tom ntej los tsim deformation lossis tawg.

4. Kev ua kom tsis tiav yog ua kom cov hlau sov rau Ac1 ~ Ac3 (sub-eutectic steel) lossis Ac1 ~ ACcm (over-eutectic steel) ntawm kev khaws cia cua sov thiab txias qeeb kom tau txais kev sib npaug ntawm cov txheej txheem kho cua sov.

II.quenching, qhov feem ntau siv txias nruab nrab yog brine, dej thiab roj.

Kev ua kom cov workpiece kub hnyiab nrog dej ntsev, yooj yim kom tau qhov nyuaj thiab du, tsis yooj yim ua rau kub hnyiab, tsis yog qhov nyuaj thiab mos, tab sis yooj yim ua rau qhov deformation ntawm workpiece loj heev, thiab txawm tias tawg. Kev siv roj ua cov khoom siv kub hnyiab tsuas yog siv rau kev ruaj khov ntawm cov austenite uas txias heev hauv qee cov hlau alloy lossis cov hlau carbon me me.

III.lub hom phiaj ntawm kev tempering hlau

1, txo qhov brittleness, tshem tawm lossis txo qhov kev ntxhov siab sab hauv, hlau quenching muaj ntau qhov kev ntxhov siab sab hauv thiab brittleness, xws li tsis raws sijhawm tempering feem ntau yuav ua rau cov hlau deformation lossis txawm tias tawg.

2, kom tau txais cov khoom siv kho tshuab uas xav tau ntawm cov khoom ua haujlwm, cov khoom ua haujlwm tom qab quenching siab hardness thiab brittleness, txhawm rau kom ua tau raws li qhov xav tau ntawm ntau yam khoom ua haujlwm sib txawv, koj tuaj yeem kho qhov nyuaj los ntawm kev tempering kom txo qhov brittleness ntawm qhov xav tau toughness, plasticity.

3, Ruaj khov qhov loj ntawm cov workpiece

4, rau kev ua kom tawv tawv, qee cov hlau alloy nyuaj rau soften, thaum quenching (lossis normalizing) feem ntau siv tom qab kub siab tempering, yog li cov hlau carbide tsim nyog aggregation, qhov nyuaj yuav raug txo, txhawm rau pab txiav thiab ua tiav.

Cov ntsiab lus ntxiv

1, annealing: hais txog cov khoom siv hlau uas raug cua sov rau qhov kub thiab txias, khaws cia rau ib lub sijhawm, thiab tom qab ntawd maj mam txias cov txheej txheem kho cua sov. Cov txheej txheem annealing feem ntau yog: recrystallization annealing, kev txo kev ntxhov siab annealing, spheroidal annealing, tiav annealing, thiab lwm yam. Lub hom phiaj ntawm annealing: feem ntau yog kom txo qhov nyuaj ntawm cov khoom siv hlau, txhim kho plasticity, txhawm rau pab txiav lossis ua haujlwm siab, txo cov kev ntxhov siab seem, txhim kho kev teeb tsa thiab cov khoom sib xyaw, lossis rau kev kho cua sov tom kawg kom ua rau lub koom haum npaj txhij.

2, normalizing: hais txog cov hlau lossis hlau uas raug cua sov rau lossis (hlau ntawm qhov kub tseem ceeb) siab tshaj 30 ~ 50 ℃ kom tswj tau lub sijhawm tsim nyog, txias hauv huab cua tseem kho cov txheej txheem cua sov. Lub hom phiaj ntawm normalizing: feem ntau yog los txhim kho cov khoom siv kho tshuab ntawm cov hlau carbon qis, txhim kho kev txiav thiab kev siv tshuab, kev ua kom zoo dua ntawm cov nplej, kom tshem tawm cov teeb meem ntawm lub koom haum, rau kev kho cua sov tom kawg los npaj lub koom haum.

3, quenching: hais txog cov hlau uas raug cua sov rau Ac3 lossis Ac1 (hlau nyob rau hauv qhov kub tseem ceeb) siab tshaj qhov kub thiab txias, khaws cia rau ib lub sijhawm, thiab tom qab ntawd mus rau qhov txias kom tsim nyog, kom tau txais martensite (lossis bainite) kev teeb tsa ntawm cov txheej txheem kho cua sov. Cov txheej txheem quenching feem ntau yog ib nrab quenching, ob nrab quenching, martensite quenching, bainite isothermal quenching, nto quenching thiab hauv zos quenching. Lub hom phiaj ntawm quenching: yog li ntawd cov khoom hlau kom tau txais lub koom haum martensitic xav tau, txhim kho qhov nyuaj ntawm cov khoom ua haujlwm, lub zog thiab kev tiv thaiv kev puas tsuaj, rau qhov kev kho cua sov tom kawg kom ua tiav kev npaj zoo rau lub koom haum.

4, tempering: hais txog cov hlau uas tau ua kom tawv, ces cua sov rau qhov kub qis dua Ac1, tuav lub sijhawm, thiab tom qab ntawd txias rau chav sov. Cov txheej txheem tempering feem ntau yog: tempering kub tsawg, tempering kub nruab nrab, tempering kub siab thiab ntau tempering.

Lub hom phiaj ntawm kev tempering: feem ntau yog kom tshem tawm qhov kev ntxhov siab uas cov hlau tsim tawm thaum lub sijhawm quenching, yog li ntawd cov hlau muaj qhov nyuaj thiab hnav tsis kam, thiab muaj qhov xav tau plasticity thiab toughness.

5, tempering: hais txog cov hlau lossis cov hlau uas siv rau kev quenching thiab tempering kub siab ntawm cov txheej txheem kho cua sov sib xyaw. Siv rau hauv kev kho tempering ntawm cov hlau hu ua tempered steel. Nws feem ntau yog hais txog cov hlau carbon nruab nrab thiab cov hlau carbon nruab nrab.

6, carburizing: carburizing yog cov txheej txheem ntawm kev ua kom cov pa roj carbon atoms nkag mus rau hauv txheej hlau. Nws kuj yog los ua kom cov hlau qis carbon workpiece muaj txheej hlau siab carbon, thiab tom qab ntawd quenching thiab tempering kub qis, yog li ntawd txheej hlau ntawm cov workpiece muaj qhov nyuaj thiab hnav tsis kam, thaum qhov chaw nruab nrab ntawm cov workpiece tseem khaws cov tawv thiab plasticity ntawm cov hlau qis carbon.

Txoj kev nqus tsev

Vim tias kev ua haujlwm cua sov thiab txias ntawm cov hlau workpieces xav tau kaum ob lossis ntau dua ntawm kev ua kom tiav. Cov kev ua no tau ua tiav hauv lub tshuab cua sov kho cua sov, tus neeg teb xov tooj tsis tuaj yeem mus txog, yog li qib ntawm kev ua haujlwm ntawm lub tshuab cua sov kho cua sov yuav tsum siab dua. Tib lub sijhawm, qee qhov kev ua, xws li cua sov thiab tuav qhov kawg ntawm cov hlau workpiece quenching txheej txheem yuav tsum yog rau, xya qhov kev ua thiab yuav tsum ua tiav hauv 15 vib nas this. Cov xwm txheej agile zoo li no kom ua tiav ntau yam kev ua, nws yooj yim ua rau tus neeg teb xov tooj ntxhov siab thiab ua rau tsis ua haujlwm. Yog li ntawd, tsuas yog qib siab ntawm kev ua haujlwm automation tuaj yeem ua tau raws li qhov tseeb, kev sib koom tes raws sijhawm raws li qhov kev pab cuam.

Kev kho cua sov ntawm cov hlau qhov chaw raug ua nyob rau hauv lub cub tawg kaw, kev kaw lub tshuab nqus tsev nruj heev yog paub zoo. Yog li ntawd, kom tau txais thiab ua raws li qhov cua tawm ntawm lub cub tawg, kom ntseeg tau tias lub tshuab nqus tsev ua haujlwm ntawm lub cub tawg, kom ntseeg tau tias qhov zoo ntawm cov khoom, kev kho cua sov nqus tsev muaj qhov tseem ceeb heev. Yog li qhov teeb meem tseem ceeb ntawm lub cub tawg kho cua sov yog kom muaj cov qauv kaw lub tshuab nqus tsev txhim khu kev qha. Txhawm rau kom ntseeg tau tias lub cub tawg ua haujlwm nqus tsev, kev tsim qauv ntawm lub cub tawg kho cua sov yuav tsum ua raws li lub hauv paus ntsiab lus yooj yim, uas yog, lub cev cub tawg siv cov roj-nruj vuam, thaum lub cev cub tawg kom qhib lossis tsis qhib qhov, tsawg dua lossis zam kev siv cov qauv kaw dynamic, kom txo qhov muaj feem cuam tshuam rau kev xau lub tshuab nqus tsev. Cov khoom siv, xws li cov electrodes txias dej, cov khoom siv thermocouple xa tawm kuj yuav tsum tsim los kaw cov qauv.

Feem ntau cov khoom siv cua sov thiab rwb thaiv tsev tsuas yog siv tau hauv qab lub tshuab nqus tsev xwb. Lub tshuab nqus tsev cua sov thiab cov ntaub thaiv tsev thermal rwb thaiv tsev yog ua haujlwm hauv lub tshuab nqus tsev thiab kub siab, yog li cov khoom siv no muaj kev tiv taus kub siab, kev cuam tshuam los ntawm hluav taws xob, kev ua haujlwm thermal thiab lwm yam uas yuav tsum tau ua. Cov kev cai rau kev tiv taus oxidation tsis siab. Yog li ntawd, lub tshuab nqus tsev cua sov siv tantalum, tungsten, molybdenum thiab graphite rau cua sov thiab rwb thaiv tsev thermal. Cov khoom siv no yooj yim heev rau oxidize hauv huab cua, yog li ntawd, lub tshuab cua sov ib txwm siv tsis tau cov khoom siv cua sov thiab rwb thaiv tsev no.

Cov khoom siv dej txias: lub tshuab cua sov kho cua sov plhaub, lub hau cua sov, cov khoom siv hluav taws xob cua sov, cov electrodes dej txias, lub qhov rooj rwb thaiv tsev cua sov nruab nrab thiab lwm yam khoom, nyob hauv lub tshuab nqus tsev, nyob rau hauv lub xeev cua sov ua haujlwm. Ua haujlwm nyob rau hauv cov xwm txheej tsis zoo no, nws yuav tsum tau ua kom ntseeg tau tias cov qauv ntawm txhua qhov khoom tsis deformed lossis puas tsuaj, thiab lub foob nqus tsev tsis overheated lossis hlawv. Yog li ntawd, txhua qhov khoom yuav tsum tau teeb tsa raws li qhov xwm txheej sib txawv ntawm cov khoom siv dej txias kom ntseeg tau tias lub tshuab cua sov kho cua sov tuaj yeem ua haujlwm ib txwm thiab muaj lub neej siv txaus.

Kev siv cov hluav taws xob tsawg tsawg tam sim no: lub thawv nqus tsev, thaum lub tshuab nqus tsev nqus tsev degree ntawm ob peb lxlo-1 torr ntau yam, lub thawv nqus tsev ntawm tus neeg coj hluav taws xob hauv qhov hluav taws xob siab dua, yuav tsim cov teeb meem tso tawm teeb pom kev zoo. Hauv lub tshuab nqus tsev kho cua sov, qhov tso tawm arc loj heev yuav hlawv cov khoom siv hluav taws xob cua sov, txheej rwb thaiv tsev, ua rau muaj xwm txheej loj thiab kev poob. Yog li ntawd, qhov hluav taws xob ua haujlwm ntawm lub tshuab nqus tsev kho cua sov feem ntau tsis pub ntau tshaj 80 txog 100 volts. Tib lub sijhawm, hauv kev tsim qauv ntawm lub tshuab cua sov hluav taws xob, yuav tsum ua cov kev ntsuas zoo, xws li sim tsis txhob muaj qhov kawg ntawm cov khoom, qhov sib nrug ntawm electrode ntawm cov electrodes yuav tsum tsis txhob me dhau, kom tiv thaiv kev tsim cov teeb pom kev zoo lossis arc tso tawm.

Kev ua kom sov

Raws li qhov sib txawv ntawm kev ua tau zoo ntawm cov workpiece, raws li nws cov kub sib txawv, tuaj yeem muab faib ua cov hom tempering hauv qab no:

(a) qhov kub tsawg (150-250 degrees)

Qhov kub qis ntawm lub koom haum tshwm sim rau cov martensite tempered. Nws lub hom phiaj yog kom tswj tau qhov nyuaj siab thiab kev hnav tsis kam ntawm cov hlau quenched nyob rau hauv lub hauv paus ntawm kev txo nws cov kev ntxhov siab sab hauv thiab brittleness, yog li kom tsis txhob chipping lossis puas tsuaj ua ntej lub sijhawm siv. Nws yog siv rau ntau yam cuab yeej txiav cov pa roj carbon siab, gauges, txias-duab dies, dov bearings thiab carburized qhov chaw, thiab lwm yam., tom qab tempering hardness feem ntau yog HRC58-64.

(ii) qhov kub nruab nrab tempering (250-500 degrees)

Lub cev tempered quartz siv rau qhov kub nruab nrab. Nws lub hom phiaj yog kom tau txais lub zog siab, kev txwv elastic thiab kev tawv siab. Yog li ntawd, nws feem ntau yog siv rau ntau yam kev ua haujlwm pwm kub, qhov nyuaj tempering feem ntau yog HRC35-50.

(C) kub siab tempering (500-650 degrees)

Kev kub siab tempering ntawm lub koom haum rau tempered Sohnite. Kev cai quenching thiab kub siab tempering ua ke kev kho cua sov hu ua tempering kev kho mob, nws lub hom phiaj yog kom tau txais lub zog, hardness thiab plasticity, toughness yog zoo dua tag nrho cov khoom siv kho tshuab. Yog li ntawd, dav siv hauv tsheb, tsheb laij teb, tshuab cuab yeej thiab lwm yam khoom tseem ceeb, xws li txuas rods, bolts, iav thiab shafts. Qhov nyuaj tom qab tempering feem ntau yog HB200-330.

Kev tiv thaiv kev hloov pauv

Feem ntau cov pwm deformation nyuaj heev, tab sis peb tsuas yog kawm nws txoj cai deformation, tshuaj xyuas nws cov ua rau, siv ntau txoj kev sib txawv los tiv thaiv pwm deformation uas tuaj yeem txo tau, tab sis kuj tuaj yeem tswj tau. Feem ntau hais lus, kev kho cua sov ntawm precision complex pwm deformation tuaj yeem siv cov txheej txheem hauv qab no los tiv thaiv.

(1) Xaiv cov khoom siv tsim nyog. Cov pwm ua los ntawm cov hlau pwm zoo yuav tsum xaiv cov khoom siv uas muaj cov hlau pwm zoo (xws li cov hlau uas tiv taus cua), thiab cov hlau pwm loj uas sib cais los ntawm cov carbide yuav tsum tau kho cua sov kom tsim nyog, thiab cov hlau pwm loj dua thiab tsis tuaj yeem kho cua sov kom zoo yuav tsum tau kho cua sov ob zaug.

(2) Kev tsim cov qauv pwm yuav tsum tsim nyog, qhov tuab yuav tsum tsis txhob sib txawv dhau, cov duab yuav tsum sib npaug, rau qhov kev hloov pauv ntawm cov pwm loj dua kom paub txog txoj cai hloov pauv, kev tso cai ua tiav, rau cov pwm loj, meej thiab nyuaj, tuaj yeem siv ua ke ntawm cov qauv.

(3) Cov pwm ua kom raug thiab cov pwm nyuaj yuav tsum tau kho ua ntej kom tshem tawm cov kev ntxhov siab seem uas tsim tawm hauv cov txheej txheem machining.

(4) Kev xaiv qhov kub thiab txias tsim nyog, tswj qhov ceev ntawm qhov cua sov, rau cov pwm ua haujlwm precision complex tuaj yeem siv cua sov qeeb, preheating thiab lwm txoj kev cua sov sib npaug kom txo qhov deformation ntawm kev kho cua sov pwm.

(5) Raws li lub hauv paus ntawm kev ua kom lub pwm tawv, sim siv cov txheej txheem ua ntej txias, qib txias quenching lossis kub quenching.

(6) Rau cov pwm precision thiab cov pwm nyuaj, nyob rau hauv cov xwm txheej tso cai, sim siv lub tshuab nqus tsev cua sov quenching thiab kev kho cua txias tob tom qab quenching.

(7) Rau qee qhov kev ua pwm precision thiab complex, koj tuaj yeem siv kev kho cua sov ua ntej, kev kho cua sov laus, thiab kev kho cua sov nitriding tempering los tswj qhov tseeb ntawm cov pwm.

(8) Thaum kho cov pwm xuab zeb qhov, porosity, hnav thiab lwm yam tsis zoo, kev siv lub tshuab vuam txias thiab lwm yam kev cuam tshuam thermal ntawm cov khoom siv kho kom tsis txhob muaj kev kho deformation.

Tsis tas li ntawd xwb, kev ua haujlwm kho cua sov kom raug (xws li kev ntsaws qhov, khi qhov, kho tshuab, cov txheej txheem cua sov tsim nyog, kev xaiv qhov kev taw qhia txias ntawm pwm thiab kev taw qhia ntawm kev txav mus los hauv qhov chaw txias, thiab lwm yam) thiab cov txheej txheem kho cua sov tempering tsim nyog yog los txo qhov deformation ntawm qhov tseeb thiab cov pwm nyuaj kuj yog cov kev ntsuas zoo.

Kev kho cua sov ntawm qhov chaw thiab kev kho cua sov feem ntau yog ua los ntawm kev siv cua sov induction lossis hluav taws kub. Cov txheej txheem tseem ceeb yog qhov nyuaj ntawm qhov chaw, qhov nyuaj hauv zos thiab qhov tob ntawm txheej tawv. Kev sim qhov nyuaj siv tau Vickers hardness tester, kuj siv tau Rockwell lossis Rockwell hardness tester ntawm qhov chaw. Kev xaiv lub zog sim (teev) muaj feem cuam tshuam nrog qhov tob ntawm txheej tawv thiab qhov nyuaj ntawm qhov chaw ua haujlwm. Muaj peb hom kev sim qhov nyuaj koom nrog ntawm no.

Ua ntej, Vickers hardness tester yog ib txoj hauv kev tseem ceeb los ntsuas qhov nyuaj ntawm cov khoom ua haujlwm uas tau kho cua sov, nws tuaj yeem xaiv los ntawm 0.5 txog 100kg ntawm lub zog sim, sim cov txheej tawv ntawm qhov chaw uas nyias li 0.05 hli tuab, thiab nws qhov tseeb yog qhov siab tshaj plaws, thiab nws tuaj yeem paub qhov txawv me me ntawm qhov nyuaj ntawm cov khoom ua haujlwm uas tau kho cua sov. Tsis tas li ntawd, Vickers hardness tester kuj yuav tsum tau kuaj pom qhov tob ntawm cov txheej tawv zoo, yog li rau kev kho cua sov ntawm qhov chaw lossis ntau lub chaw siv cov khoom ua haujlwm kho cua sov ntawm qhov chaw, nruab nrog Vickers hardness tester yog qhov tsim nyog.

Qhov thib ob, lub Rockwell hardness tester ntawm qhov chaw kuj tsim nyog heev rau kev sim qhov nyuaj ntawm qhov chaw ua haujlwm tawv, lub Rockwell hardness tester ntawm qhov chaw muaj peb qhov ntsuas xaiv los ntawm. Nws tuaj yeem sim qhov tob ntawm qhov tawv ntawm ntau dua 0.1 hli ntawm ntau yam khoom siv tawv. Txawm hais tias qhov tseeb ntawm lub Rockwell hardness tester ntawm qhov chaw tsis siab npaum li Vickers hardness tester, tab sis ua lub chaw kho cua sov zoo thiab kev tshuaj xyuas tsim nyog, nws tau ua tau raws li qhov yuav tsum tau ua. Ntxiv mus, nws kuj muaj kev ua haujlwm yooj yim, yooj yim siv, tus nqi qis, ntsuas sai, tuaj yeem nyeem qhov nyuaj thiab lwm yam ntxwv ncaj qha, kev siv lub Rockwell hardness tester ntawm qhov chaw tuaj yeem ua ib pawg ntawm cov khoom siv kho cua sov rau kev sim sai thiab tsis ua puas tsuaj. Qhov no yog qhov tseem ceeb rau kev ua hlau thiab chaw tsim khoom siv tshuab.

Qhov thib peb, thaum lub txheej tawv ntawm kev kho cua sov yog tuab dua, kuj siv tau Rockwell hardness tester. Thaum lub txheej tawv ntawm kev kho cua sov yog 0.4 ~ 0.8 hli, siv tau HRA scale, thiab thaum lub txheej tawv yog ntau tshaj 0.8 hli, siv tau HRC scale.

Peb hom Vickers, Rockwell thiab nto Rockwell hardness tuaj yeem hloov pauv tau yooj yim rau ib leeg, hloov pauv mus rau tus qauv, kos duab lossis tus neeg siv xav tau tus nqi hardness. Cov lus hloov pauv sib xws tau muab rau hauv tus qauv thoob ntiaj teb ISO, tus qauv Asmeskas ASTM thiab tus qauv Suav GB / T.

Kev ua kom tawv hauv zos

Yog tias qhov chaw nyuaj hauv zos xav tau siab dua, muaj cua sov induction thiab lwm txoj hauv kev kho cua sov hauv zos, cov khoom no feem ntau yuav tsum cim qhov chaw kho cua sov hauv zos thiab tus nqi nyuaj hauv zos ntawm cov duab kos. Kev kuaj qhov nyuaj ntawm cov khoom yuav tsum tau ua nyob rau hauv thaj chaw tshwj xeeb. Cov cuab yeej kuaj qhov nyuaj tuaj yeem siv Rockwell hardness tester, kuaj HRC hardness tus nqi, xws li kev kho cua sov hardening txheej yog ntiav, tuaj yeem siv qhov chaw Rockwell hardness tester, kuaj HRN hardness tus nqi.

Kev kho cua sov tshuaj lom neeg

Kev kho cua sov tshuaj yog ua kom ib lossis ntau yam tshuaj lom neeg ntawm cov atoms nkag mus rau saum npoo ntawm cov khoom ua haujlwm, yog li hloov pauv cov tshuaj lom neeg, kev teeb tsa thiab kev ua haujlwm ntawm qhov chaw ntawm cov khoom ua haujlwm. Tom qab quenching thiab tempering kub qis, qhov chaw ntawm cov khoom ua haujlwm muaj qhov nyuaj siab, hnav tsis kam thiab kev sib cuag qaug zog, thaum lub plawv ntawm cov khoom ua haujlwm muaj qhov tawv siab.

Raws li cov saum toj no, qhov kev ntes thiab sau qhov kub hauv cov txheej txheem kho cua sov yog qhov tseem ceeb heev, thiab kev tswj qhov kub tsis zoo muaj kev cuam tshuam loj rau cov khoom. Yog li ntawd, qhov kev ntes qhov kub yog qhov tseem ceeb heev, qhov sib txawv ntawm qhov kub hauv tag nrho cov txheej txheem kuj tseem ceeb heev, ua rau cov txheej txheem kho cua sov yuav tsum tau sau tseg ntawm qhov hloov pauv ntawm qhov kub, tuaj yeem pab txhawb kev tshuaj xyuas cov ntaub ntawv yav tom ntej, tab sis kuj pom lub sijhawm twg qhov kub tsis ua raws li qhov yuav tsum tau ua. Qhov no yuav ua lub luag haujlwm tseem ceeb heev hauv kev txhim kho kev kho cua sov yav tom ntej.

Cov txheej txheem ua haujlwm

1. Ntxuav qhov chaw ua haujlwm, xyuas seb lub hwj chim, cov cuab yeej ntsuas thiab ntau yam hloov pauv puas zoo li qub, thiab seb qhov dej puas du.

2. Cov neeg ua haujlwm yuav tsum hnav cov khoom siv tiv thaiv kev ua haujlwm zoo, txwv tsis pub nws yuav txaus ntshai.

3, qhib lub hwj chim tswj hwm thoob ntiaj teb hloov pauv, raws li cov kev cai ntawm cov khoom siv qib siab ntawm qhov kub nce thiab poob, kom txuas lub neej ntawm cov khoom siv thiab cov khoom siv kom zoo.

4, kom them sai sai rau qhov kub thiab txias ntawm lub cub tawg thiab kev tswj ceev ntawm txoj siv sia, tuaj yeem ua tiav cov qauv kub uas xav tau rau cov ntaub ntawv sib txawv, kom ntseeg tau tias qhov nyuaj ntawm cov khoom ua haujlwm thiab qhov ncaj ntawm qhov chaw thiab txheej oxidation, thiab ua haujlwm zoo ntawm kev nyab xeeb.

5, Yuav kom them sai sai rau qhov kub ntawm lub cub tawg thiab qhov ceev ntawm txoj siv sia, qhib qhov cua tso pa tawm, kom cov khoom ua haujlwm tom qab tempering kom ua tau raws li qhov yuav tsum tau ua zoo.

6, hauv kev ua haujlwm yuav tsum lo rau ntawm tus ncej.

7, los kho cov khoom siv hluav taws uas tsim nyog, thiab paub txog kev siv thiab kev txij nkawm.

8. Thaum nres lub tshuab, peb yuav tsum xyuas kom meej tias txhua lub qhov hloov pauv tswj tau nyob hauv lub xeev kaw, thiab tom qab ntawd kaw lub qhov hloov pauv hloov pauv thoob ntiaj teb.

Kub dhau

Los ntawm lub qhov ncauj ntxhib ntawm cov khoom siv dov, cov khoom siv dov tuaj yeem pom tom qab quenching microstructure overheating. Tab sis txhawm rau txiav txim siab qhov tseeb ntawm overheating yuav tsum tau saib xyuas microstructure. Yog tias nyob rau hauv GCr15 steel quenching lub koom haum nyob rau hauv qhov zoo li ntawm koob martensite coarse, nws yog quenching overheating lub koom haum. Qhov laj thawj rau kev tsim ntawm quenching cua sov kub yuav siab dhau lossis cua sov thiab tuav lub sijhawm ntev dhau los ntawm tag nrho cov overheating; kuj tseem yuav yog vim lub koom haum thawj ntawm cov carbide band loj, nyob rau hauv thaj chaw qis carbon ntawm ob bands los tsim ib qho chaw martensite koob tuab, ua rau muaj kev overheating hauv zos. Residual austenite nyob rau hauv lub koom haum superheated nce, thiab qhov ruaj khov ntawm qhov loj me txo qis. Vim yog overheating ntawm lub koom haum quenching, cov hlau siv lead ua coarse, uas yuav ua rau txo qis hauv qhov toughness ntawm cov khoom, kev cuam tshuam tsis kam txo qis, thiab lub neej ntawm cov kabmob kuj txo qis. Overheating hnyav tuaj yeem ua rau quenching tawg.

Tsis kub txaus

Qhov kub quenching qis lossis txias tsis zoo yuav tsim ntau dua li tus qauv Torrhenite lub koom haum hauv microstructure, hu ua lub koom haum underheating, uas ua rau qhov nyuaj poob qis, hnav tsis kam txo qis, cuam tshuam rau lub neej ntawm cov menyuam cov kabmob.

Kev tua cov kab nrib pleb

Cov khoom siv dov thaum lub sijhawm quenching thiab txias vim muaj kev ntxhov siab sab hauv, cov kab nrib pleb hu ua quenching cracks. Cov laj thawj ntawm cov kab nrib pleb no yog: vim qhov kub thiab txias siab dhau lossis txias sai dhau, kev ntxhov siab thermal thiab qhov ntim ntawm cov hlau hloov pauv, kev ntxhov siab ntau dua li lub zog tawg ntawm cov hlau; qhov chaw ua haujlwm ntawm qhov tsis zoo thawj zaug (xws li qhov tawg lossis khawb ntawm qhov chaw) lossis qhov tsis zoo sab hauv ntawm cov hlau (xws li slag, cov khoom tsis yog hlau loj, cov pob dawb, cov khoom seem shrinkage, thiab lwm yam) thaum quenching, kev tsim cov concentration ntawm kev ntxhov siab; kev sib cais ntawm qhov chaw thiab Carbide loj heev; cov khoom quenched tom qab tempering tsis txaus lossis tempering tsis raws sijhawm; kev ntxhov siab txias los ntawm cov txheej txheem dhau los loj dhau, forging folding, txiav tob, roj grooves ntse ntug thiab lwm yam. Hauv ntej, qhov ua rau muaj kab nrib pleb quenching tej zaum yuav yog ib lossis ntau yam ntawm cov yam saum toj no, qhov muaj kev ntxhov siab sab hauv yog qhov laj thawj tseem ceeb rau kev tsim cov kab nrib pleb quenching. Cov kab nrib pleb quenching yog tob thiab nyias, nrog rau qhov tawg ncaj thiab tsis muaj xim oxidized ntawm qhov chaw tawg. Nws feem ntau yog qhov tawg tiaj tiaj lossis tawg zoo li lub nplhaib ntawm lub dab tshos bearing; cov duab ntawm lub pob hlau bearing yog S-puab, T-puab lossis lub nplhaib-puab. Cov yam ntxwv ntawm kev teeb tsa ntawm qhov tawg quenching tsis muaj qhov tshwm sim decarburization ntawm ob sab ntawm qhov tawg, pom tseeb qhov sib txawv ntawm cov tawg forging thiab cov khoom tawg.

Kev kho cua sov deformation

NACHI cov khoom siv bearing hauv kev kho cua sov, muaj kev ntxhov siab thermal thiab kev ntxhov siab ntawm lub koom haum, qhov kev ntxhov siab sab hauv no tuaj yeem sib tshooj lossis qee qhov sib txawv, nws nyuaj thiab hloov pauv, vim nws tuaj yeem hloov pauv nrog qhov kub thiab txias, qhov nrawm cua sov, hom txias, qhov nrawm txias, cov duab thiab qhov loj ntawm cov khoom, yog li kev kho cua sov deformation yog qhov tsis zam. Paub thiab paub txog txoj cai lij choj tuaj yeem ua rau qhov deformation ntawm cov khoom siv bearing (xws li lub voj voog ntawm lub dab tshos, qhov loj me, thiab lwm yam) tso rau hauv qhov ntau yam tswj tau, uas ua rau muaj kev tsim khoom. Tau kawg, hauv cov txheej txheem kho cua sov, kev sib tsoo tshuab kuj tseem yuav ua rau cov khoom deformation, tab sis qhov deformation no tuaj yeem siv los txhim kho kev ua haujlwm kom txo qis thiab zam kev puas tsuaj.

Kev tshem tawm ntawm qhov chaw

Cov khoom siv rau cov menyuam uas muaj cov kabmob hauv cov txheej txheem kho cua sov, yog tias nws raug cua sov hauv qhov nruab nrab oxidizing, qhov chaw yuav raug oxidized kom cov pa roj carbon ntawm qhov chaw ntawm cov khoom txo qis, ua rau qhov decarburization ntawm qhov chaw. Qhov tob ntawm cov txheej decarburization ntawm qhov chaw ntau dua li qhov kev ua tiav zaum kawg ntawm qhov ntau ntawm kev khaws cia yuav ua rau cov khoom raug pov tseg. Kev txiav txim siab ntawm qhov tob ntawm cov txheej decarburization ntawm qhov chaw hauv kev tshuaj xyuas metallographic ntawm txoj kev metallographic muaj thiab txoj kev microhardness. Cov kab faib microhardness ntawm cov txheej saum npoo yog raws li txoj kev ntsuas, thiab tuaj yeem siv ua qhov kev txiav txim siab.

Qhov chaw mos mos

Vim tsis muaj cua sov txaus, tsis txias txaus, thiab kev ua haujlwm quenching tsis zoo los ntawm qhov nyuaj ntawm cov khoom siv roller bearing tsis txaus, qhov no yog qhov tshwm sim hu ua quenching soft spot. Zoo li qhov decarburization ntawm qhov chaw ua rau qhov kev poob qis ntawm kev hnav tsis kam thiab lub zog qaug zog ntawm qhov chaw.

Lub sijhawm tshaj tawm: Lub Kaum Ob Hlis-05-2023