1. Txheej txheem cej luam ntawm cov khoom

Lub ladle hlau tsim raws liASTM A27 Qib 70-36yog ib qho hlau ua los ntawm cov pa roj carbon uas ua haujlwm hnyav uas tsim los rau kev tuav, kev thauj mus los, thiab kev tswj ib ntus ntawm cov slag molten lossis cov ntaub ntawv kub hauv cov ntawv thov metallurgical thiab kev lag luam.

Qib no yog xaiv tshwj xeeb los muab qhov sib npaug zoo tshaj plaws ntawmlub zog, ductility, thiab kev tiv taus thermal thiab mechanical kev ntxhov siab, ua rau nws tsim nyog rau cov ladles uas raug kev ua haujlwm nqa ntau zaus, kev hloov pauv thermal, thiab kev thauj khoom cuam tshuam.

2. Tus Qauv Siv Tau

ASTM A27 / A27M- Cov Hlau Castings, Carbon, rau Daim Ntawv Thov Dav Dav

Khoom Qib:ASTM A27 Qib 70-36

Txhua qhov castings yuav tsum tau tsim, sim, thiab tshuaj xyuas kom ua raws li cov kev cai ntawm ASTM A27 tshwj tsis yog tias tus neeg yuav khoom tau teev tseg lwm yam.

3. Cov Yam Ntxwv ntawm Cov Khoom Siv - ASTM A27 Qib 70-36

ASTM A27 Qib 70-36 yog qib carbon steel nruab nrab uas muaj cov khoom zoo thiab kev ntseeg tau.

3.1 Cov Khoom Siv Kho Tshuab (Yam Tsawg Kawg Nkaus)

| Vaj tse | Qhov Yuav Tsum Tau Ua |

| Lub zog tensile | ≥ 70,000 psi (≈ 485 MPa) |

| Lub Zog Tawm | ≥ 36,000 psi (≈ 250 MPa) |

| Kev ntev (hauv 2 nti / 50 hli) | ≥ 22% |

| Kev txo qis ntawm thaj chaw | ≥ 30% |

Cov khoom siv kho tshuab no ua kom muaj peev xwm thauj khoom txaus thaum tseem tswj tau qhov kev tiv thaiv zoo heev rau kev tawg thiab tawg yooj yim.

3.2 Cov Tshuaj Lom Zem (Cov Kev Txwv Ib Txwm Muaj)

| Khoom | Cov Ntsiab Lus Tshaj Plaws |

| Cov pa roj carbon (C) | ≤ 0.35% |

| Manganese (Mn) | ≤ 0.70% |

| Phosphorus (P) | ≤ 0.05% |

| Sulfur (S) | ≤ 0.06% |

Cov pa roj carbon thiab manganese uas tswj tau pab txhawb rau qhov zoo ntawm kev casting thiab kev ua haujlwm ntawm cov khoom siv txhim khu kev qha yam tsis tas yuav siv cov khoom sib xyaw.

4. Tsim thiab Cov Qauv ntawm Lub Ladle

l Ib daim cam khwb cia lub cev lossis cam khwb cia lub cev nrog cov hooks nqa / nqa lugs

l Cov qauv sab hauv du kom txo qhov kev ntxhov siab

u Phab ntsa tuab txaus tsim los tiv taus cov thermal gradients thiab cov khoom siv kho tshuab

l Cov ntsiab lus tsa tau tsim los ntawm kev nqa khoom puv ntoob, suav nrog cov yam ntxwv kev nyab xeeb

Tus qauv tsim ntawm lub ladle qhia txogkev ruaj khov ntawm cov qauv thiab kev ua haujlwm ntev, tshwj xeeb tshaj yog nyob rau hauv qhov kub thiab txias thiab kev siv crane ntau zaus.

5. Txheej Txheem Tsim Khoom

5.1 Txoj Kev Ua Casting

l Kev siv cov khoom siv molding uas tswj tau uas tsim nyog rau cov hlau loj castings

l Kev siv cua sov ib zaug xwb yog pom zoo kom paub tseeb tias cov tshuaj lom neeg sib xws

5.2 Yaj thiab nchuav

l Hluav taws xob arc cub tawg (EAF) lossis induction cub tawg

Kev tswj hwm nruj ntawm cov tshuaj lom neeg ua ntej nchuav

l Tswj qhov kub thiab txias kom txo tau qhov tsis zoo sab hauv

5.3 Kev Kho Mob Kub

Kev kho cua sov kom zoo li qubfeem ntau yog siv

Lub Hom Phiaj:

l Txhim kho cov qauv ntawm cov noob

l Txhim kho qhov muaj zog thiab cov khoom siv kho tshuab zoo sib xws

l Txo kev ntxhov siab sab hauv

Cov kev ntsuas kev kho cua sov yuav tsum tau sau tseg thiab taug qab tau.

6. Kev Tswj Xyuas Zoo thiab Kev Tshuaj Xyuas

6.1 Kev Tshuaj Xyuas Tshuaj

l Kev tshuaj xyuas cua sov ua rau txhua qhov yaj

Cov txiaj ntsig tau sau tseg rau hauv Daim Ntawv Pov Thawj Xeem Zeb (MTC)

6.2 Kev Ntsuas Tshuab

l Cov daim coupon kuaj pov los ntawm tib lub cua sov thiab cua sov kho ua ke nrog lub ladle:

l Kev sim Tensile

l Kev txheeb xyuas lub zog ntawm cov qoob loo

l Kev ntev thiab txo qis ntawm thaj chaw

6.3 Kev Tshuaj Xyuas Tsis Ua Rau Puas Tsuaj (yog siv tau)

Nyob ntawm seb qhov project xav tau dab tsi:

l Kev soj ntsuam pom (100%)

l Kev Ntsuas Cov Khoom Sib Nqus (MT) rau cov kab nrib pleb ntawm qhov chaw

Kev Ntsuas Ultrasonic (UT) rau kev ruaj ntseg sab hauv

6.4 Kev Tshuaj Xyuas Qhov Ntev

l Kev txheeb xyuas cov duab kos uas tau pom zoo

l Kev saib xyuas tshwj xeeb rau kev nqa cov qauv ntawm cov nuv thiab cov seem tseem ceeb ntawm cov khoom thauj

7. Cov Ntaub Ntawv thiab Daim Ntawv Pov Thawj

Cov ntaub ntawv hauv qab no feem ntau yog muab:

Daim Ntawv Pov Thawj Xeem Zeb (EN 10204 3.1 lossis sib npaug)

l Daim ntawv qhia txog cov tshuaj lom neeg

l Cov txiaj ntsig ntawm kev sim tshuab

l Cov ntaub ntawv kho cua sov

Cov ntawv qhia NDT (yog tias xav tau)

Daim ntawv qhia txog kev tshuaj xyuas qhov ntev

Tag nrho cov ntaub ntawv tuaj yeem taug qab mus rau qhov kub thiab casting batch.

8. Daim Ntawv Thov Scope

Cov lauj kaub hlau uas tsim los rau ASTM A27 Qib 70-36 yog siv dav hauv:

l Cov nroj tsuag hlau thiab cov chaw ua hlau

l Cov txheej txheem tswj cov slag

l Cov chaw cob qhia txog kev ua hlau

l Kev ua haujlwm hloov khoom siv hauv kev lag luam hnyav

Qib no tshwj xeeb tshaj yog rau cov ntawv thov uasductility thiab kev nyab xeeb nyob rau hauv dynamic loadyog qhov tseem ceeb.

9. Cov txiaj ntsig ntawm kev siv ASTM A27 Qib 70-36 rau cov Ladles

l Kev sib npaug zoo ntawm lub zog thiab ductility

Txo qhov kev pheej hmoo ntawm kev tawg tawg hauv qab thermal shock

l Tus nqi zoo piv rau cov qib siab dua, qib qis dua

l Kev ntseeg tau zoo rau cov ntawv thov casting hnyav

Kev lees txais dav los ntawm cov neeg soj ntsuam thiab cov tuam txhab engineering

Cov Ntaub Ntawv Txog Kev Ntim Khoom & Kev Thauj Mus Los

Cov NCM pom zoo (Tus lej them nqi):8454100000

Hom Ntim Khoom Siv:

Cov ntoo skid los yog crate ua raws li kev cai rau kev thauj mus los hauv hiav txwv.

Cov roj tiv thaiv xeb lossis cov zaj duab xis tiv thaiv xeb uas siv rau ntawm cov chaw.

Siv cov hlua hlau thiab ntoo thaiv kom ruaj ntseg kom tsis txhob muaj kev txav mus los thaum lub sijhawm thauj mus los.

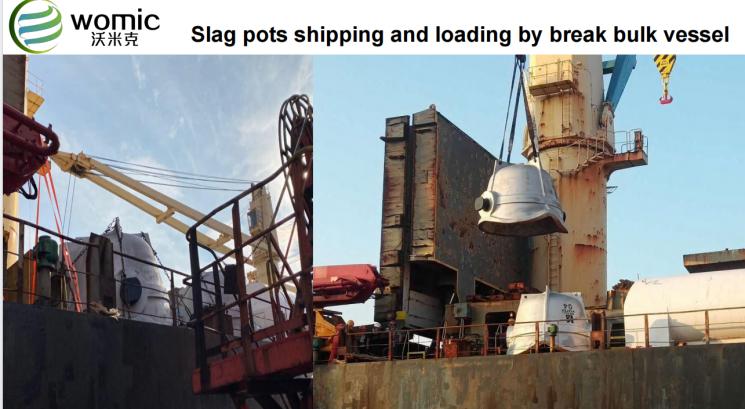

Hom kev xa khoom:Thawv,lub nkoj loj:

Thawv Rack tiaj tus- Nyiam dua rau qhov yooj yim ntawm crane loading / unloading.

Qhib Lub Thawv Sab Saum Toj- Siv thaum qhov kev tshem tawm ntsug yog qhov txhawj xeeb.

Lub Nkoj Loj- Rau qhov loj me tsis tuaj yeem thauj khoom rau hauv cov thawv

Xav tau daim ntawv tso cai rau kev thauj mus los hauv zos?

Yog, vim yog qhov loj ntawm cov lauj kaub, ibdaim ntawv tso cai thauj khoom tshwj xeebfeem ntau yuav tsum muaj rau kev xa khoom los ntawm txoj kev lossis tsheb ciav hlau. Cov ntaub ntawv thiab cov duab kos duab tuaj yeem muab los pab nrog daim ntawv thov daim ntawv tso cai.

Yog tias muaj cov khoom thauj loj heev, yuav siv hom khoom siv twg los tuav?

Crawler Cranesnrog lub peev xwm txaus rau qhov me me thiab qhov hnyav.

Cov cranes ntug dej hiav txwvrau cov lauj kaub slag hnyav dua 28tons

Txhua qhov chaw nqa khoom tau tsim thiab sim kom ntseeg tau tias muaj kev nyab xeeb thiab ua raws li txoj cai.

10. Xaus Lus

ASTM A27 Qib 70-36 yog ib qho khoom siv zoo thiab siv tau nyiaj tsawg rau cov hlau siv rau hauv cov chaw ua haujlwm nyuaj. Nws cov khoom siv kho tshuab, ua ke nrog kev tswj hwm tshuaj lom neeg thiab kev kho cua sov kom zoo, muab kev ntseeg siab thiab kev nyab xeeb rau kev ua haujlwm ntev.

Peb txaus siab rau peb tus kheejkev pabcuam kho kom haum, cov voj voog tsim khoom sai, thiabkev xa khoom thoob ntiaj teb, xyuas kom meej tias koj cov kev xav tau tshwj xeeb tau raug ua tiav nrog kev ua tib zoo thiab kev ua tau zoo.

Lub Vas Sab: www.womicsteel.com

Email: sales@womicsteel.com

Xov tooj/WhatsApp/WeChat: Victor: +86-15575100681 los yog Jack: +86-18390957568

Lub sijhawm tshaj tawm: Lub Ib Hlis-22-2026