1. Txheej Txheem Cej Luam ntawm Lub Tuam Txhab

Womic Steel yog lub tuam txhab tsim cov kav dej thiab cov raj hlau tsis xeb uas paub thoob ntiaj teb, tshwj xeeb hauv cov khoom siv zoo rau cov ntawv thov tseem ceeb. Nrog ntau xyoo ntawm kev paub dhau los thiab lub chaw tsim khoom zoo tshaj plaws, peb tau tso peb tus kheej ua tus khub txhim khu kev qha rau cov lag luam uas xav tau kev ua haujlwm raug, kev ruaj khov, thiab kev lees paub zoo. Peb cov raj SA213-TP304L seamless yog tsim los rau cov chaw ua haujlwm siab, muab kev tiv thaiv corrosion tsis sib xws, lub zog kho tshuab, thiab kev ua haujlwm zoo.

2. Cov Qauv Siv Tau

Peb cov raj SA213-TP304L yog tsim ua raws li ASTM A213/A213M, uas qhia txog cov raj ferritic thiab austenitic alloy-steel boiler, superheater, thiab heat-exchanger uas tsis muaj qhov sib txuas. Ntxiv mus, peb cov khoom ua tau raws li qhov yuav tsum tau ua ntawm ASME Seem II rau cov hlab siab thiab tau ntawv pov thawj raws li ISO 9001: 2015 thiab PED 2014/68/EU. Kev tshuaj xyuas los ntawm cov neeg thib peb xws li TUV, SGS, Lloyd's Register, thiab DNV tuaj yeem npaj los txhawb cov ntaub ntawv tshwj xeeb thiab kev tswj xyuas zoo.

3. Qhov Loj thiab Khoom Ntau Yam

Womic Steel muaj cov raj SA213-TP304L hauv ntau qhov ntau thiab tsawg los pab txhawb rau ob qho tib si tus qauv thiab kev siv kho kom haum:

- Sab nraud txoj kab uas hla: 6mm rau273.1hli (1/4" mus rau10")

- Phab ntsa tuab: 0.5 hli txog 12 hli

- Ntev: Txog li 12 meters lossis kho kom haum rau cov neeg siv khoom

Peb kuj muab kev kam rau siab nruj nrog OD deviation txog li ± 0.05 hli thiab phab ntsa thickness precision txog li ± 0.03 hli. Peb cov kab ntau lawm txhawb nqa metric thiab imperial sizing, nrog rau kev txiav, khoov, thiab beveling kev pabcuam.

4. Cov Khoom Siv Tshuaj thiab Tshuab

SA213-TP304L yog cov hlau tsis muaj carbon tsawg uas ua los ntawm 304 stainless hlau uas ua kom muaj kev vuam zoo dua thiab txo qhov kev pheej hmoo ntawm kev xeb intergranular tom qab vuam. Nws cov khoom sib xyaw tau kho kom zoo rau kev ntseeg tau hauv qhov kub thiab txias thiab qhov chaw xeb:

Cov Tshuaj Muaj Peev Xwm Ib Txwm Muaj:

- Cov pa roj carbon (C): ≤ 0.035%

- Chromium (Cr): 18.0–20.0%

- Nickel (Ni): 8.0–12.0%

- Manganese (Mn): ≤ 2.00%

- Silicon (Si): ≤ 1.00%

- Phosphorus (P): ≤ 0.045%

- Sulfur (S): ≤ 0.030%

Lub Zog Kho Tshuab:

- Lub zog tensile: ≥ 485 MPa

- Lub zog tawm los: ≥ 170 MPa

- Kev ntev: ≥ 35%

- Qhov nyuaj: ≤ 90 HRB

Qhov kev sib xyaw ua ke no ua kom muaj kev ua tau zoo tshwj xeeb hauv cov txheej txheem siab, cov chaw muaj tshuaj lom neeg hnyav, thiab cov ntawv thov thermal cycling siab.

5. Kev Tsim Khoom Siv Siab Tshaj Plaws

Womic Steel lub raj SA213-TP304L yog tsim los ntawm kev siv cov kauj ruam tsim khoom uas tswj tau zoo:

1. Kev Xaiv Khoom Siv Raw: Peb yuav cov billets los ntawm cov neeg muag khoom hauv tsev zoo tshaj plaws nrog cov khoom sib xws ruaj khov. Txhua yam khoom siv raw raug txheeb xyuas siv cov thev naus laus zis Positive Material Identification (PMI).

2. Kev Tho Kub: Kev rho tawm kub siab ua rau cov qauv khoob, ua kom cov qauv noob sib xws thiab qhov sib npaug zoo tshaj plaws.

3. Kev Kos Duab Txias: Cov kauj ruam no ua rau cov khoom siv kho tshuab zoo dua, txo qhov roughness ntawm qhov chaw, thiab coj cov raj mus rau lawv qhov ntev kawg.

4. Kev Ua Kub Kub Rau Cov Tshuaj: Ua ntawm 1050–1150°C ua raws li kev tua dej sai sai, cov kauj ruam no txo qhov kev ntxhov siab sab hauv thiab txhim kho kev tiv thaiv xeb.

5. Pickling thiab Passivation: Cov nplaim ntawm lub raj yog acid-treated thiab chemically passivated los kho cov txheej oxide tiv thaiv.

6. Kev Ncaj Thiab Kev Ntsuas Loj: Cov raj xa dej raug dhau los ntawm ntau lub tshuab dov kom zoo meej thiab ntsuas raws li qhov yuav tsum tau ua.

6. Cov Txheej Txheem Kev Ntsuas Uas Ruaj Khoov

Yuav kom lav qhov zoo sib xws, Womic Steel yuam kom muaj kev sim hauv tsev thiab sab nraud:

Kev Ntsuas Hydrostatic: Paub meej tias txhua lub raj muaj kev ncaj ncees nyob rau hauv cov xwm txheej siab.

Kev Ntsuas Tam Sim No Eddy: Nrhiav cov kab nrib pleb me me thiab cov kev tsis sib txuas yam tsis ua rau lub raj puas tsuaj.

Kev Tshuaj Xyuas Ultrasonic: Tshawb xyuas qhov sib npaug ntawm cov qauv sab hauv thiab nrhiav pom qhov tsis zoo uas zais cia.

Kev Ntsuas Kev Sib Tsoo Intergranular (IGC): Txheeb xyuas qhov kev tiv thaiv kev sib txhuam tom qab vuam.

Kev Ntsuas Tensile thiab Hardness: Cov khoom siv kho tshuab raug kuaj raws li ASTM A370 kom ntseeg tau tias ua raws li tag nrho.

Kev Tshuaj Xyuas Qhov Chaw Tiav: Paub meej tias ua raws li Ra ≤ 1.6μm (lossis zoo dua, raws li qhov yuav tsum tau ua).

7. Cov Ntawv Pov Thawj thiab Kev Ntsuam Xyuas Zoo

Txhua pawg khoom xa tuaj nrog Daim Ntawv Pov Thawj Xeem Mill (MTC) tag nrho raws li EN 10204 3.1 lossis 3.2. Womic Steel lub Hoobkas tau ntawv pov thawj rau ISO 9001: 2015, thiab peb yog cov neeg muab khoom tau pom zoo rau ntau lub tuam txhab EPC thoob ntiaj teb. Txhua yam khoom siv siab tau ntawv pov thawj raws li ASME Boiler thiab Pressure Vessel Code thiab European Pressure Equipment Directive (PED).

8. Kev Lag Luam Daim Ntawv Thov

Lub raj SA213-TP304L siv dav hauv:

Kev Tsim Hluav Taws Xob: Superheaters, reheaters, thiab condensers

Cov Chaw Tsim Tshuaj thiab Petrochemical: Cov kab ua haujlwm thiab cov hlab siab

Tshuaj: Cov pa dej huv thiab WFI (Dej rau Kev Txhaj Tshuaj) cov txheej txheem

Khoom Noj thiab Dej Haus: Kev thauj mus los ntawm cov kua dej huv

Kev Tsim Kho Marine: Cov khoom sib pauv cua sov thiab cov kav dej txias hauv dej hiav txwv

Roj thiab Roj Av: Kev xa roj mus rau sab qis thiab cov kab hluav taws xob

Nws txoj kev tiv taus corrosion thiab lub peev xwm los tiv taus kev ntxhov siab thermal cyclic ua rau nws tseem ceeb heev rau hauv qhov chaw ib puag ncig hnyav.

9. Lub voj voog tsim khoom thiab lub sijhawm xa khoom

Womic Steel muab cov sijhawm xa khoom zoo tshaj plaws hauv kev lag luam uas txhawb nqa los ntawm cov saw hlau muab khoom yooj yim thiab kev tsim khoom loj:

- Lub Sijhawm Ua Khoom Siv Txheem:15–25 hnub ua haujlwm

- Kev xa khoom sai rau cov xaj ceev: sai li 10 hnub ua haujlwm

- Muaj Peev Xwm Ntau Lawm Txhua Hli: Tshaj 1200 metric tons

- Cov Khoom Siv Raw: Ntau tshaj 500 tons npaj txhij rau kos duab hauv Tshuag

Qhov no ua kom muaj kev ywj pheej thiab kev ntseeg tau, txawm tias nyob rau hauv cov sijhawm ua haujlwm nruj.

10. Kev Ntim Khoom thiab Kev Tshawb Xyuas Tau

Peb lub ntim khoom ua kom muaj kev tiv thaiv tag nrho thiab kev taug qab thaum lub sijhawm thauj mus los thiab khaws cia:

- Cov hau yas kawg tiv thaiv kev ua qias tuaj

- Muab khi thiab qhwv rau hauv zaj duab xis tiv thaiv xeb thiab cov siv sia

- Cov ntoo crates lossis pallets seaworthy rau kev xa khoom containerized

- Txhua pob khoom muaj tus lej cua sov, qhov loj me, cov khoom siv, ID pawg, thiab QR code.

Qhov no tso cai rau cov neeg siv khoom taug qab txhua lub raj rov qab mus rau nws cov cua sov tsim khoom kom pom tseeb tag nrho.

11. Lub zog ntawm kev thauj mus los thiab kev xa khoom

Womic Steel ua haujlwm los ntawm cov chaw nres nkoj loj hauv Suav teb, muab kev xa khoom thoob ntiaj teb zoo:

- Kev xa khoom FCL thiab LCL nrog kev txhim kho thawv

- Cov hlua khi hlau thiab cov ntoo wedges los ruaj ntseg cov khoom thauj

- Kev koom tes nrog cov neeg xa khoom zoo tshaj plaws rau kev xa khoom raws sijhawm

- Kev txhawb nqa kev tshem tawm kev lis kev cai thiab kev sib koom tes tshuaj xyuas ua ntej xa khoom

Cov neeg siv khoom tau txais txiaj ntsig los ntawm kev hloov kho tshiab ntawm kev xa khoom tiag tiag thiab ETAs raug.

12. Kev Ua Haujlwm Hauv Tsev thiab Kev Tsim Khoom

Peb mus dhau qhov kev tsim cov raj xa dej los ntawm kev muab cov kev pabcuam ua tiav raws li koj xav tau:

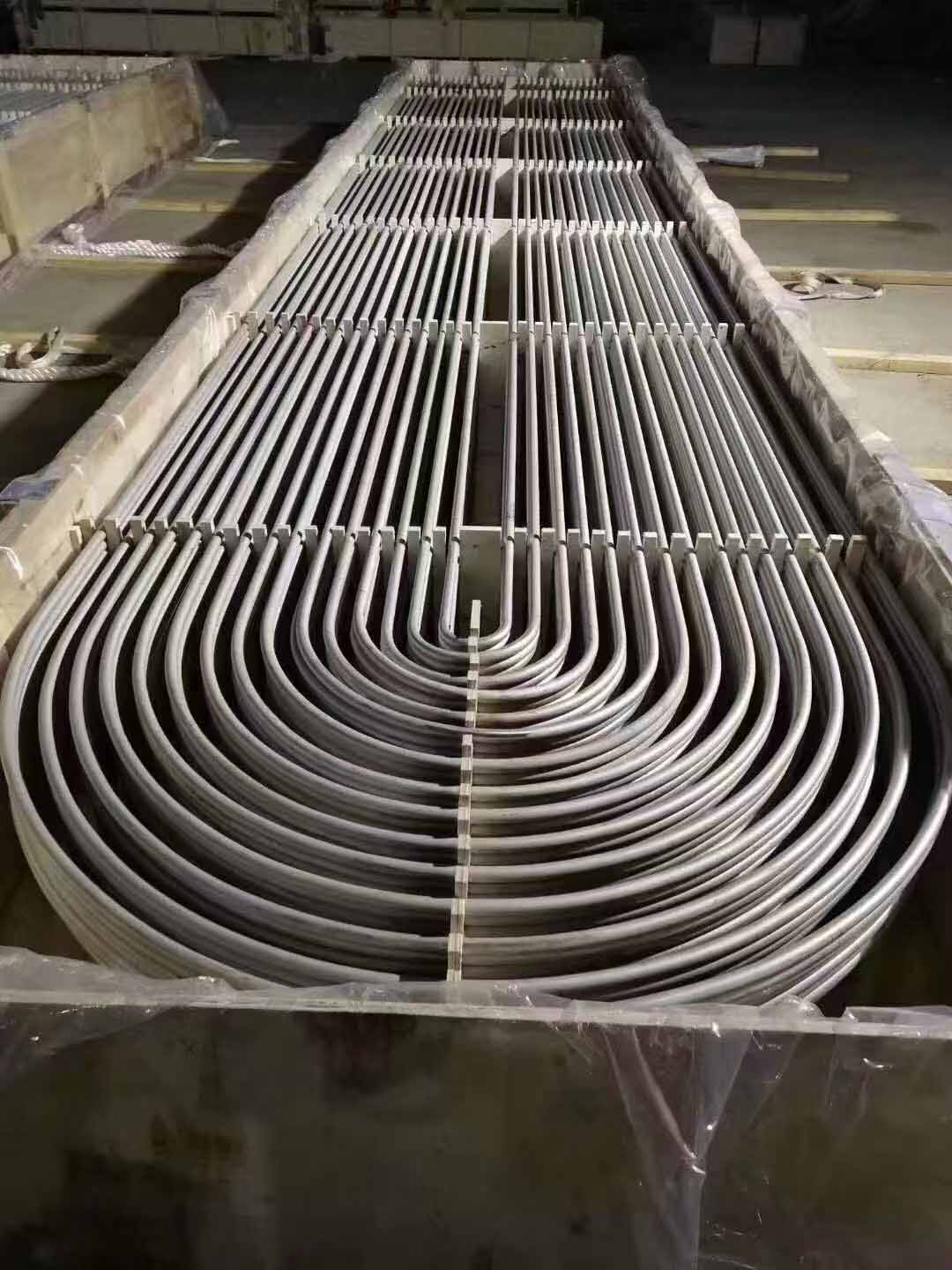

- U-bending thiab serpentine coil tsim

- Xaus beveling, threading, thiab facing

- Qhov thiab perforation rau cov raj lim dej

- Kev txhuam nto (Ra ≤ 0.4μm rau kev siv huv)

Cov kev pabcuam ntxiv no tshem tawm qhov xav tau cov neeg muag khoom thib ob, txuag cov neeg siv khoom lub sijhawm thiab tus nqi.

13. Vim li cas ho xaiv Womic Steel?

Womic Steel muab cov kev daws teeb meem stainless hlau puv ntoob nrog cov txiaj ntsig tsis sib xws:

- Muaj cov khoom siv raw sai los ntawm kev koom tes ntev ntawm cov chaw tsim khoom

- Cov kab tsis siv neeg rau kev kos duab, annealing, thiab kev tshuaj xyuas

- Cov kws tshaj lij engineers uas muaj ntau tshaj 20 xyoo kev paub txog kev ua haujlwm hauv thaj teb

- Kev pabcuam rau cov neeg siv khoom thiab kev txhawb nqa ntau hom lus

- Kev tswj xyuas zoo hauv qhov chaw thiab 100% kev taug qab

Txij li ntawm cov qauv tsim mus rau qhov ntau thiab tsawg, peb ua kom muaj kev ntseeg siab, kev sib xws, thiab kev txaus siab ntawm cov neeg siv khoom.

Xaiv Womic Steel Group ua koj tus khub txhim khu kev qha rauCov kav hlau tsis xebthiab kev ua tau zoo tshaj plaws ntawm kev xa khoom. Txais tos nug!

Lub Vas Sab: www.womicsteel.com

Email: sales@womicsteel.com

Xov tooj/WhatsApp/WeChat: Victor: +86-15575100681 los yog Jack: +86-18390957568

Lub sijhawm tshaj tawm: Plaub Hlis-21-2025