1. Txheej txheem cej luam ntawm cov khoom siv

347H cov yeeb nkab stainless hlau yog cov hlau stainless hlau uas muaj cov pa roj carbon ntau thiab ruaj khov uas paub txog nws lub zog kub siab, kev vuam zoo heev, thiab kev tiv thaiv zoo rau kev xeb intergranular. Kev ntxiv niobium (Nb) txhim kho lub zog nkag thiab tiv thaiv chromium carbide los ntawm cov ciam teb ntawm cov noob, ua kom ntseeg tau tias muaj kev tiv thaiv zoo rau kev hnov lus.

2.Cov Tshuaj Lom Zem (Ib txwm muaj)

| Khoom | Cov ntsiab lus (%) |

| C | 0.04 – 0.10 |

| Cr | 17.0 – 19.0 |

| Ni | 9.0 – 13.0 |

| Si | ≤1.0 |

| Mn | ≤ 2.00 |

| P | ≤ 0.045 |

| S | ≤ 0.030 |

3. Cov Khoom Siv Kho Tshuab & Kev Sib Tsoo

Cov Khoom Siv Kho Tshuab (ASTM A213):

- Lub zog tensile ≥ 515 MPa

- Lub zog tawm los ≥ 205 MPa

- Kev ntev ≥ 35%

- Lub zog tawg ntawm 600 ° C: >100 MPa

Kev Tiv Thaiv Kev Xeb:

- Zoo heev intergranular corrosion tsis kam vim Nb stabilization

- Zoo tiv taus hauv nitric acid, acetic acid, alkaline ib puag ncig, thiab dej hiav txwv

- Kuaj rau kev xeb ntawm cov ntsev uas yaj, ua pov thawj tias ua tau zoo hauv CSP cov tso tsheb cia ntsev uas yaj

- Muaj kev cuam tshuam me ntsis rau cov pitting uas ua rau chloride tshwm sim dua li 316L, txo qis los ntawm kev passivation thiab kev kho qhov chaw

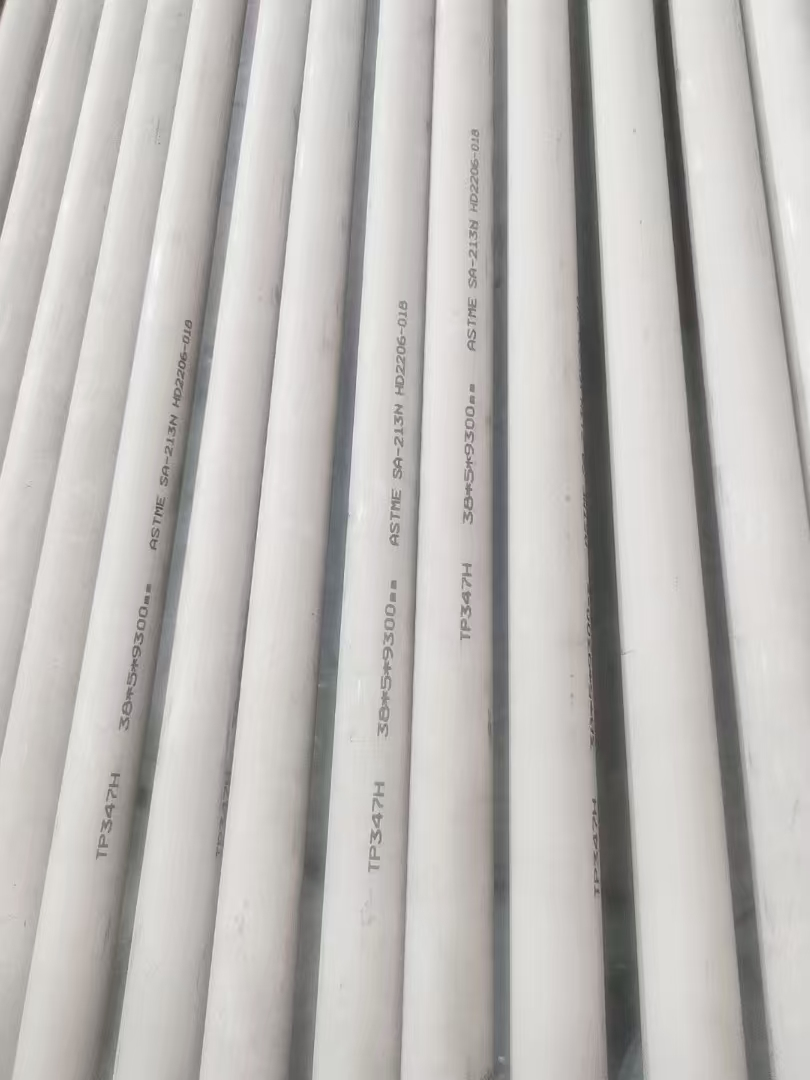

4. Cov Lus Qhia Txog Khoom Siv

Qhov Loj:

- Cov Yeeb Nkab Seamless: OD 1/4 "–36", phab ntsa tuab SCH10–SCH160

- Cov raj xa dej precision: OD 10mm–108mm, kos txias

- Cov Yeeb Nkab Vuam: Cov yeeb nkab nyias mus rau tuab siv TIG, PAW, thiab SAW vuam

- Ntev: Txog li 12 meters; kev cai txiav ntev muaj

Cov Qauv Tsim Khoom:

- ASTM A213/A312, ASME SA213/SA312

- EN 10216-5, GB/T 5310

- Ua raws li lub thawv siab: PED, AD2000 W0, ASME Code Section VIII Div. 1

5. Txheej Txheem Tsim Khoom

1. Cov Khoom Siv Raw: Cov hlau billets uas tau ntawv pov thawj los ntawm cov chaw tsim khoom hauv tsev thiab thoob ntiaj teb

2. Kub Dov: Cov hlau billets kub txog 1150–1200 ° C, tho thiab dov rau cov kav dej loj lossis phab ntsa tuab

3. Kev Kos Duab Txias: Kev kos duab txias ntau zaus rau qhov loj me thiab qhov chaw tiav

4. Kev Kho Mob Kub: Kev kub hnyiab ntawm 980–1150 ° C, kev tua dej sai sai kom txo tau cov carbide precipitation

5. Kev Vuam: GTAW (TIG), PAW, thiab SAW cov txheej txheem, siv ER347 filler wire rau kev ruaj khov; muaj cov kev xaiv rov qab purging

6. Kev Ua Tiav Ntawm Qhov Chaw: Pickling, passivation (HNO₃/HF), thiab mechanical polishing (Ra ≤ 0.2µm thaum thov)

7. Kev Tshuaj Xyuas: 100% RT (kev kuaj duab hluav taws xob) rau cov vuam; ultrasonic, hydrostatic, PMI, kev kuaj xeb intergranular raws li qhov xav tau

6. Daim Ntawv Pov Thawj & Kev Tswj Xyuas Zoo

Womic Steel cov kav dej stainless hlau 347H tau ntawv pov thawj raws li:

- ISO 9001: 2015

- PED 2014/68/EU

- AD2000 W0

- ASME Boiler & Pressure Vessel Code

Txhua pawg khoom raug kuaj xyuas kom zoo, suav nrog:

- Kev ntsuam xyuas tshuab (tensile, impact, flattening, flaring)

- Kev ntsuam xyuas xeb (IGC ib ASTM A262)

- Kev sim tsis puas tsuaj (UT, RT, Eddy tam sim no)

- Kev tshuaj xyuas qhov ntev thiab kev taug qab tag nrho

7. Cov Ntawv Thov

347H stainless hlau yeeb nkab yog dav siv rau hauv:

- Kev Tsim Hluav Taws Xob: Superheaters, reheaters, cov kav dej loj hauv cov chaw tsim hluav taws xob thermal subcritical thiab supercritical

- Lub Zog Thermal Los Ntawm Hnub Ci: Cov thoob dej kub uas yaj hauv ntsev (450–565°C), tau siv tau zoo hauv cov haujlwm thoob plaws Suav teb (Yumen, Haixi)

- Petrochemical: Cov raj cua sov, cov reactors hydroprocessing (tiv taus H₂-H₂S-H₂O ib puag ncig)

- Aerospace: Cov kav dej tso pa tawm ntawm lub cav thiab cov kav dej cua turbine (ua haujlwm txog li 850 ° C)

- Cov Khoom Siv Hloov Kub: Cov condenser kub thiab cov kav dej hauv cov chaw ua roj thiab cov kab ke hauv dej hiav txwv

8. Lub Sijhawm Ua Khoom

- Cov Raj Tsis Muaj Qhov Txuas (Qhov Loj Txheem): 15–25 hnub

- Qhov Loj Tshwj Xeeb / Cov Kav Dej Phab Ntsa Tuab: 30–45 hnub

- Cov Lus Txiav Txim Loj: Muaj peev xwm ntau dua 3,000 tons / hli ua kom xa khoom sai txawm tias nyob rau lub sijhawm ceev ceev

9. Kev Ntim Khoom & Kev Xa Khoom

Womic Steel muab cov ntim khoom ruaj ntseg thiab hloov kho tau:

- Cov Ntoo Seaworthy lossis Cov Ncej Hlau Bundles

- Cov hau yas kawg, roj tiv thaiv xeb, thiab qhwv zaj duab xis

- Txhua lub thawv xa khoom raws li ISPM-15 tus qauv

Qhov Zoo ntawm Kev Thauj Khoom:

- Cov nqi CIF / CFR sib tw

- Kev xa khoom sai sai rau chaw nres nkoj mus rau sab hnub tuaj Asia, Is Nrias teb, Tebchaws Europe, thiab Middle East

- Muaj zog thauj khoom rau kev tiv thaiv kev khoov, tiv thaiv kev plam, thiab tiv thaiv kev sib tsoo thaum lub sijhawm xa khoom

10. Cov Kev Pabcuam Ua Haujlwm

- Khoov (txias thiab kub-ua)

- Kev Txiav Txim Siab

- Xov thiab Xaus tiav

- Kev sib dhos vuam (spools thiab lub luj tshib)

- Kev cai machining ib daim duab

11. Vim li cas ho xaiv Womic Steel?

- Chav Kuaj Xyuas thiab Txhim Kho hauv Tsev

- Cov khoom siv raw khoom ruaj khov ua kom cov voj voog xa khoom luv luv

- Ntau xyoo ntawm kev paub txog kev ua hlau, tshwj xeeb tshaj yog hauv cov hlau kub siab

- Kev taug qab tag nrho thiab cov ntaub ntawv pov thawj rau kev ua raws li cov khoom siv siab

- Ib qho chaw muab kev daws teeb meem rau kev yuav khoom, kev ua tiav, thiab kev xa tawm ntawm cov kav dej hlau tsis xeb

Yog xav tau cov ntaub ntawv qhia txog kev siv tshuab, tus nqi, thiab cov lus hais txog qhov project, hu rau Womic Steel hnub no. Peb npaj txhij los txhawb koj cov kev xav tau ntawm cov kav dej ua haujlwm siab nrog kev ua haujlwm raug, ceev, thiab kev ncaj ncees.

Xaiv Womic Steel Group ua koj tus khub txhim khu kev qha rauCov kav hlau tsis xebthiab kev ua tau zoo tshaj plaws ntawm kev xa khoom. Txais tos nug!

Lub Vas Sab: www.womicsteel.com

Email: sales@womicsteel.com

Xov tooj/WhatsApp/WeChat: Victor: +86-15575100681 los yog Jack: +86-18390957568

Lub sijhawm tshaj tawm: Plaub Hlis-16-2025